-

64

-

(4)

Recovering procedures

a) According to the instructions for handling the refrigerant recovering equipment (described in the attached instruction manual),

operate the equipment to recover refrigerant.

b) During the operation, take care of the following cautions.

1

Ascertain that the refrigerant recovering equipment is running as required and always monitor the state of operation so that

adequate steps can be taken in an emergency.

2

During the operation, remain at work site to ensure safety.

3

If you have to leave your work site for any unavoidable reason, stop the operation after ascertaining that the recovering

cylinder is not overcharged.

c) During the operation, if the refrigerant recovering equipment’s overcharging prevention mechanism operates and the equip-

ment stops automatically, replace the recovering cylinder with an empty one.

d) If the pressure gauge’s reading increases after a short time from the accomplishment of recovery and automatic stoppage of the

refrigerant recovering equipment, restart the equipment and, if it stops again, finish the recovery.

(5)

Procedures after recovery

a) Close the valves on the air conditioner subjected to refrigerant recovery, the refrigerant recovering equipment and the recover-

ing cylinder.

b) Detach the recovering cylinder charged with refrigerant and store it as required by law.

7.4.2 Accessories/tools

In order to carry out R410A recovery, a variety of accessories/tools are required.

Shown below are standard accessories.

(1)

Recovering cylinder

• Use a recovering cylinder designated by the equipment manufacturer.

• A detachable cylinder must be such that it complies with the laws and regulations concerned.

• Do not use an ordinary cylinder as a recovering cylinder.

Note 1: A cylinder available when R410A was purchased, is a borrowed one.

Note 2: As a cylinder available when R410A was purchased, is provided with a check valve, it cannot be used as a recovering

cylinder.

• Types (by function)

• Caution

It is prohibited by law to recover R410A into a throw-away service can or one-way cylinder.

(2)

Drier

• A desiccant container for removing the water content of R410A.

• A drier should be prepared as expendables.

• Keep the drier sealed just before fitting it.

• Required to protect the R410A recovering equipment.

(3)

Connection hose

a) Charge port and charge port packing

• Usually, it is sold independently of a refrigerant cylinder.

• In the case of a two-port cylinder, the diameter may be special.

Inquire the manufacture for confirmation.

• A packing is expendables.

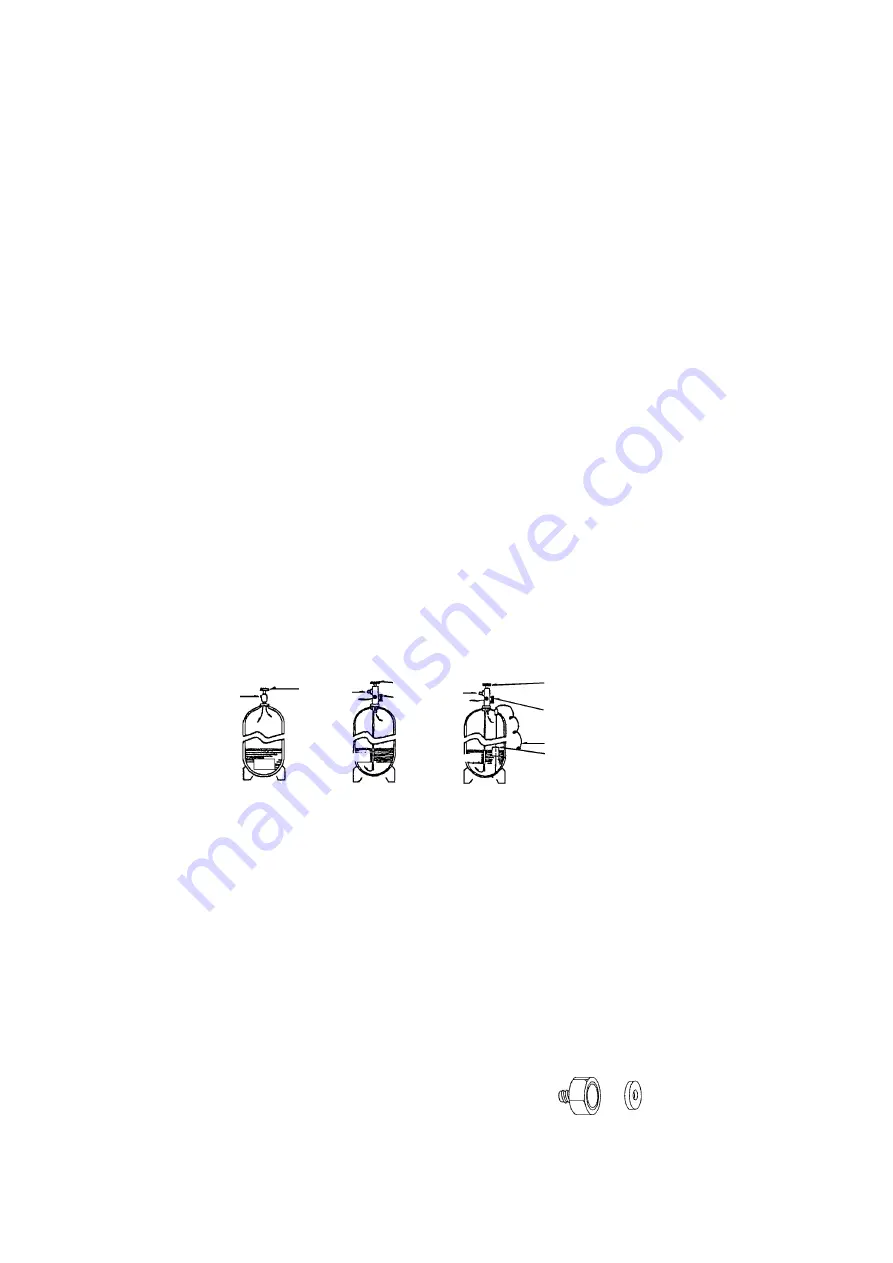

Fig.8 Cylinder types

Valve

Valve for liquid

Valve for gas

Liquid

Liquid

Valve for liquid the tube is inserted to

a level close to the cylinder bottom.

Valve for gas

(for gas releasing)

Signal line

Float

Liquid

(a) Basic type

• 1-port valve

• Can be used for

R410A recovery.

• Inverted when

delivering liquid

R410A.

(b) 2-port valve type

• Capable of delivering

liquid R410A or

releasing gas in the

upright position.

• Convenient for

servicing.

(c) Float type special

cylinder

• With a built-in float

(signal) for prevention of

overcharging

(c)

}

Charge port