-

-

'10 • SRK-T-098

-

2

-

'10 • SRK-T-098

................................................................ 61

....................................................... 57

9.2 Models SRK20

~

35ZJX-S ...................................................................... 56

(2) Unit ON/OFF button

............................................................................ 57

(1) Operation control function by remote controller

................................... 56

(4) Custom cord switching procedure

(3) Auto restart function

........................................................................... 57

(9) Outline of heating operation

(5) Flap and louver control

..................................................................... 58

(8) Installation location setting

.................................................................. 60

(6) 3D auto operation

.............................................................................. 59

(7) Timer operation

.................................................................................... 60

(10) Outline of cooling operation

............................................................. 62

(11) Outline of automatic operation

............................................................ 62

(12) Protective control function

................................................................... 63

(13) Defrost heater control

....................................................................... 68

............................................................................... 69

10.4 Troubleshooting procedure (If the air conditioner runs)

10.3 Troubleshooting procedure (If the air conditioner does not run at all) .... 69

10.1 Cautions

............................................................................................... 69

10.2 Items to check before troubleshooting ............................................... 69

10.10 How to make sure of wireless remote controller ............................. 86

10.11 Outdoor unit inspection points

......................................................... 87

10.5 Self-diagnosis table

............................................................................ 71

10.6 Service mode (Trouble mode access function)

................................. 72

10.8 Phenomenon observed after shortcircuit, wire breakage on sensor ...... 84

10.7 Inspection procedures corresponding to detail of trouble ............... 80

10.9 Checking the indoor electrical equipment

........................................ 85

10. MAINTENANCE DATA

11.1 Instullation of wired remote controller (RC-E4)

............................... 89

11. OPTION PARTS

....................................................................................... 89

11.2 Interface kit (SC-BIKN-E)

.................................................................... 95

11.3 Super link E board (SC-ADNA-E)

....................................................... 99

■

How to read the model name

Example: SRK 20 Z

Series code

Inverter type

Product capacity

Model name

JX-S

SRK : Wall mounted type

SRC : Outdoor unit

.................. 70

'09•SRK-DB-087D

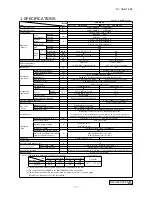

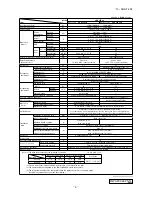

Model

Item

SRK25ZJ-S

Indoor unit

SRK25ZJ-S

Outdoor unit

SRC25ZJ-SA

Cooling capacity (1)

W

2500 (1000 (Min.) ~ 2900 (Max.))

Heating capacity (1)

W

3200 (1200 (Min.) ~ 4200 (Max.))

Power supply

1 Phase, 220 ~ 240 V, 50Hz

Operation

data (1)

Power

consumption

Cooling

kW

0.62 (0.21 ~ 0.88)

Heating

0.80 (0.27 ~ 1.36)

Running

current

Cooling

A

3.2 / 3.1 / 3.0 (220/ 230/ 240 V)

Heating

4.0 / 3.8 / 3.7 (220/ 230/ 240 V)

Inrush current

4.0 / 3.8 / 3.7 (220/ 230/ 240 V)

COP

Cooling

4.03

Heating

4.00

Noise

level

Cooling

Sound level

dB (A)

Hi: 34 Me: 28 Lo: 21

48

Power level

dB

50

60

Heating

Sound level

dB (A)

Hi: 39 Me: 31 Lo: 24

49

Power level

dB

55

61

Exterior dimensions (Height x Width x Depth)

mm

294×798×229

540×780(+62)×290

Exterior appearance

( Munsell color )

Fine snow

Stucco white

( 8.0Y 9.3/0.1 ) near equivalent

( 4.2Y 7.5/1.1 ) near equivalent

Net weight

kg

9.5

32

Refrigerant

equipment

Compressor type & Q'ty

—

RM-B5077MDE1 ( Rotary type ) x 1

Motor (Starting method)

kW

—

0.75 ( Line starting )

Refrigerant oil

0.35 ( DIAMOND FREEZE MA68 )

Refrigerant (3)

kg

R410A 0.75 (Pre-Charged up to the piping length of 15m)

Heat exchanger

Louver fins & inner grooved tubing

M fins & inner grooved tubing

Refrigerant control

Capillary tubes + Electronic expansion valve

Deice control

Microcomputer control

Air handling

equipment

Fan type & Q'ty

Tangential fan x 1

Propeller fan x 1

Motor

W

38

24

Air flow

Colling

CMM

Hi: 7.9 Me: 6.0 Lo: 5.0

32.1

Heating

Hi: 10.6 Me: 6.5 Lo: 5.1

25.6

Fresh air intake

Not possible

—

Air filter, Quality / Quantity

Polypropylene net ( washable ) x 2

—

Shock & vibration absorber

—

—

Cushion rubber ( for compressor )

Electric heater

Defrost heater 230V 110W

Operation

control

Operation switch

Wireless-Remote control

—

Room temperature control

Microcomputer thermostat

—

Operation Display

RUN: Green, TIMER: Yellow, HI POWER: Green, 3D AUTO: Green

Safety devices

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Heating overload protection( High pressure control ), Cooling overload protection

Installation

data

Refrigerant piping size ( O.D )

mm

Liquid line:

Ǿ

6.35 ( 1/4" ) Gas line:

Ǿ

9.52 ( 3/8" )

connecting method

Flare connecting

Attached length of piping

m

Liquid line : 0.53

—

Gas Line : 0.40

Insulation for piping

Necessary ( Both sides ), independent

Refrigerant line (one way )length

m

Max.15

Vertical height difference between

outdoor unit and indoor unit

Max.10 ( Outdoor unit is higher )

Max.10 ( Outdoor unit is lower )

Drain hose

Connectable ( VP 16 )

—

Power cable

—

Recommended breaker size

A

16

Connection wiring

Size x Core numbe

1.5mm

2

x 4 cores ( Including earth cable )

Connecting method

Terminal block ( Screw fixing type )

Accessories (included)

Mounting kit, Clean filter ( Allergen clear filter x 1, Photocatalytic washable deodorizing filter x 1 )

Optional parts

Interface kit ( SC-BIKN-E )

Adapted to

RoHS directive

Item

Operation

Indoor air temperature

Outdoor air temperature

Standards

DB

WB

DB

WB

Cooling

27ºC

19ºC

35ºC

24ºC

ISO-T1 , JIS C 9612

Heating

20ºC

—

7ºC

6ºC

Note (1) The data are measured at the following conditions.

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220/230/240V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 15m connecting piping.

(Purging is not required even for the short piping.)

The pipe length is 7.5m.

RWA000Z225

B