-

42

-

'10 • SRK-T-098

'09•SRK-DB-087D

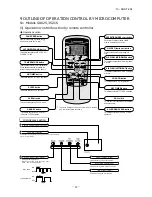

Cable name plate

Power supply terminal block

○

It holds cables in place and protect the terminal

connection from external force.

○

This clamp is for the cable in the outside

diameter 9~15mm.

Please adjust it when not suitable.

○

Please be sure to carry out D-type (type III)

grounding work.

○

It has stuck on the lid of a control box.

Grounding terminal

Cable clamp

Indoor - Outdoor

connecting wire

Power cable

power cable, indoor - outdoor connecting wire circuit diagram

CAUTION

Please connect the earthed line of indoor and outdoor

connecting wire to a bracket part of the illustration

CAUTION

Power cable, indoor-outdoor connecting wires

Always use an earth leakage circuit breaker designed for inverter circuits to

prevent a faulty operation.

●

Always perform grounding system installation work with the power cord unplugged.

Outdoor unit

Switchgear or Circuit breaker

1

1

2/N

2/N

3

1 2/N 3

Indoor unit

Earth leakage breaker

(Harmonic resistant type)

Interconnecting and

grounding wires

(minimum)

20

25

35

2.0

mm

2

30A

16A

1.5

mm

2

×4

15A,30mA,

0.1sec or less

Switchgear or Circuit Breaker

Switch breaker Over current protector

rated capacity

Earth leakage breaker

●

The specifications shown in the above table are for units without heaters. For units with heaters, refer to

the installation instructions or the construction instructions of the indoor unit.

●

Switchgear or Circuit breaker capacity which is calculated from MAX. over current should be chosen along the

regulations in each country.

●

The cable specifications are based on the assumption that a metal or plastic conduit is used with no more than

three cables contained in a conduit and a voltage drop is 2%. For an installation falling outside of these

conditions, please follow the internal cabling regulations. Adapt it to the regulation in effect in each country.

Power souce

(minimum)

Model

Phase

Single-phase

INSTALLATION TEST CHECK POINTS

After installation

Check the following points again after completion of the installation, and before turnig on the power. Conduct a test run again and ensure that the unit operates properly.

Explain to the customer how to use the unit and how to take care of the unit following the instruction manual.

Power cables and connecting wires are securely fixed to the terminal block.

The power supply voltage is correct as the rating.

The drain hose is fixed securely.

Operational valve is fully open.

No gas leaks from the joints of the operational valve.

The pipe joints for indoor and outdoor pipes have been insulated.

The reverse flow check cap is attached.

The cover of the pipe cover (A) faces downward to prevent rain from entering.

Gaps are properly sealed between the pipe covers (A) (B) and the wall surface / pipes.