'20 • SRF-DB-310

-

35

-

2. OUTDOOR UNIT INSTALLATION

Note as a unit designed for R32

• Do not use any refrigerant other than R32. R32 will rise to pressure about 1.6 times higher than that of

a conventional refrigerant. A cylinder containing R32 has a light blue indication mark on the top.

• Do not use a charge cylinder. The use of a charge cylinder will cause the refrigerant composition to

change, which results in performance degradation.

• In charging refrigerant, always take it out from a cylinder in the liquid phase.

• All indoor units must be models designed exclusively for R32. Check connectable indoor unit models in

a catalog, etc. (A wrong indoor unit, if connected into the system, will impair proper system operation)

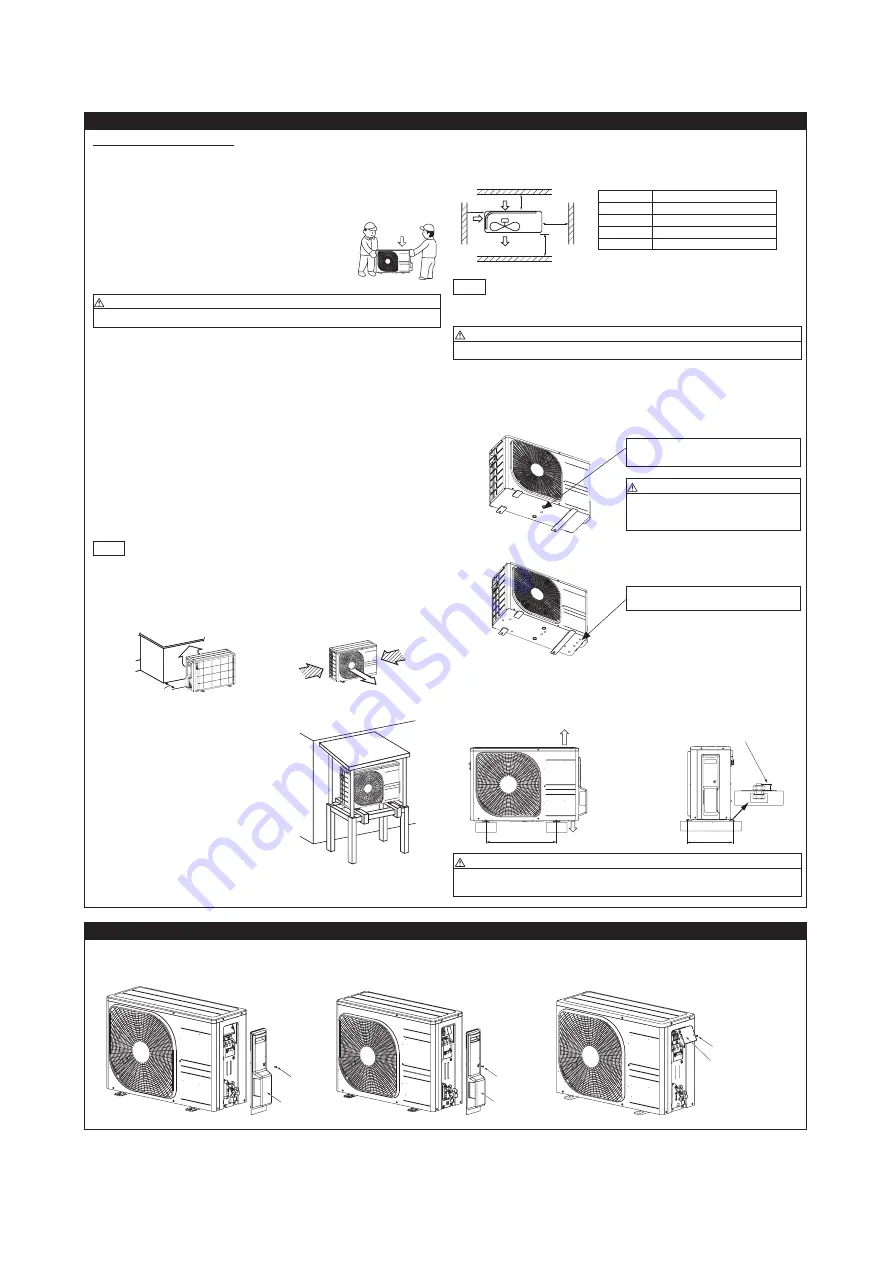

1. Haulage

• Always carry or move the unit with two or more persons.

• The right hand side of the unit as viewed from the front (outlet side) is

heavier.

A person carrying the right hand side must take care of this fact. A per-

son carrying the left hand side must hold the handle provided on the

front panel of the unit with his right hand and the corner column section

of the unit with his left hand.

CAUTION

When a unit is hauled, take care of its gravity center position which is shifted towards right hand side.

If the unit is not hauled properly, it can go off balance and fall resulting in serious injury.

2. Selecting the installation location

Select the suitable installation location where:

• Unit will be stable, horizontal and free of any vibration transmission.

• There is no obstacle which can prevent smooth air circulation from inlet and outlet side of the unit.

• There is enough space for service and maintenance of unit.

• Neighbours are not bothered by noise or air generating from the unit.

• Outlet air of the unit does not blow directly to animals or plants.

• Drain water can be discharged properly.

• There is no risk of flammable gas leakage.

• There are no other heat sources nearby.

• Unit is not directly exposed to rain or sunlight.

• Unit is not directly exposed to oil mist and steam.

• Chemical substances like ammonia (organic fertilizer), calcium chloride (snow melting agent) and acid

(sulfurous acid etc.), which can harm the unit, will not generate or accumulate.

• Unit is not directly exposed to corrosive gases (like sulphide gas, chloride gas), sea breeze or salty

atmosphere.

• No TV set or radio receiver is placed within 1 m.

• Unit is not affected by electromagnetic waves and/or high-harmonic waves generated by other equipments.

• Strong wind does not blow against the unit outlet.

• Heavy snowfalls do not occur (If installed, provide proper protection to avoid snow accumulation).

NOTE

If the unit is installed in the area where there is a possibility of strong wind or snow accumulation, the fol-

lowing measures are required.

(1) Location of strong wind

• Place the unit with its outlet side facing the wall. • Place the unit such that the direction of air from

the outlet gets perpendicular to the wind direction.

Over 500mm

Wind

direction

Wind

direction

(2) Location of snow accumulation

• Install the unit on the base so that the bottom is

higher than snow cover surface.

• Install the unit under eaves or provide the roof on

site.

3. Installation space

• There must be 1 m or larger space between the unit and the wall in at least 1 of the 4 sides. Walls

surrounding the unit from 4 sides is not acceptable. The wall height on the outlet side should be 1200

mm or less. Refer to the following figure and table for details.

NOTE

When more than one unit are installed side by side, provide a 250 mm or wider interval between them

as a service space.

CAUTION

When more than one unit are installed in parallel directions, provide sufficient inlet space so that short-cir

-

cuiting may not occur.

4. Drain piping work (If necessary)

Carry out drain piping work by using a drain elbow and a drain grommet supplied separately as acces-

sories if condensed water needs to be drained out.

(1) Install drain elbow and drain grommet.

(2) Seal around the drain elbow and drain grommet with putty or adequate caulking material.

<SRC20/25/35/50ZS-W>

Do not put a grommet on this hole.

This is a supplementary drain hole to discharge

drain water, when a large amount of it is gathered.

CAUTION

Do not use drain elbow and drain grommet if there

is a possibility to have several consecutive days of

sub zero temperature. (There is a risk of drain water

freezing inside and blocking the drain.)

<SRC20/25/35ZS-WA>

Do not block the drain holes when installing the

outdoor unit.

5. Installation

• Install the unit on a flat level base.

• While installing the unit, keep space and fix the unit’s legs with 4 anchor bolts as shown in the figure

below. The protrusion of an anchor bolt from the foundation surface must be kept within 15 mm.

200mm over

If drain piping work was carried

out, keep the clearance more

than 100mm.

510mm

313mm

15m

m

Anchor bolt (M10-12) × 4 pcs.

CAUTION

• Install the unit properly so that it does not fall over during earthquake, strong wind, etc.

•

Make sure that unit is installed on a flat level base. Installing unit on uneven base may result in unit

malfunction.

3. PREPARATION FOR WORK

1. Removing service cover

Remove the screw. Slide service cover downwards and remove it.

2. Removing terminal cover

Remove the screw and take out terminal cover.

(For SRC50, terminal cover is attached to service cover.

Therefore, there is no need to remove terminal cover separately.)

Heavy

Screw

Service cover

<SRC20/25/35>

<SRC50>

Screw

Terminal cover

Screw

Service cover

Installation space (mm)

L1

280 or more

L2

100 or more

L3

80 or more

L4

250 or more

Inlet

(

Service

space

)

Inlet

Outlet

L3

L4

L1

L2