-64-

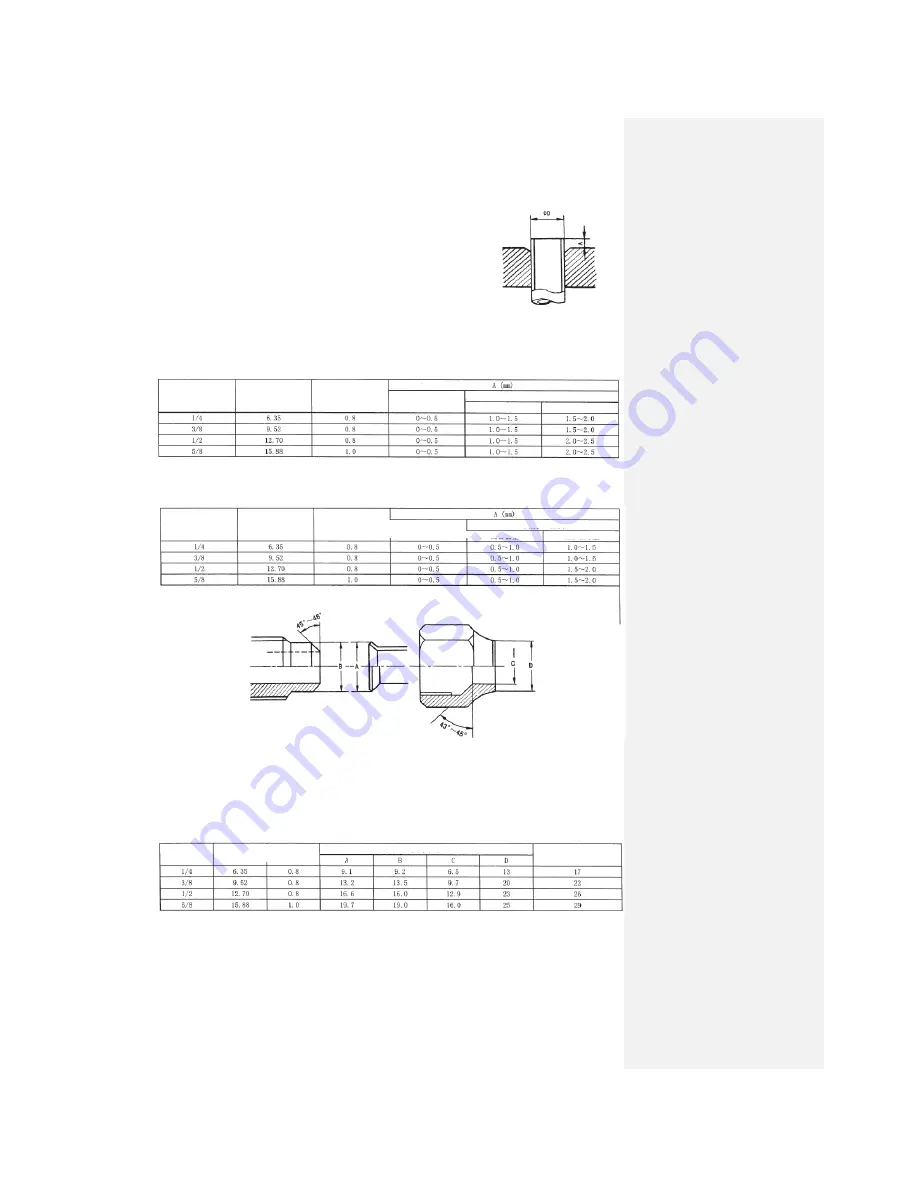

d) Flaring

Ensure to clean the clamps and copper pipes.

Use the clamping bars to conduct flaring correctly.

Use the flare tools for R410A or conventional flare tools.

The size of flaring varies depending on the kinds of flare tool.

Please note that the size must be adjusted to “Size A” with the

size adjustment scaled rule when using conventional flare tools.

Figure 3 Flare tool

Table 5 R410A flaring sizes

Table 6 R22 flaring sizes

Figure 4 Relationship between flare nut and flaring sealing surface

Table 7 Sizes of R410A flaring and flare nut

[Unit: mm]

Rating

diameter

Outside

diameter

Width of

flare nut

Size

Thickness

Rating diameter Outside diameter

(mm)

Thickness

(mm)

Flare tool for R410A

Clutch type

Conventional flare tools

Clutch type

Wing nut type

Rating diameter Outside diameter

(mm)

Thickness

(mm)

Flare tool for R410A

Clutch type

Conventional flare tools

Clutch type

Wing nut type

Summary of Contents for SRC25QA-S

Page 10: ... 7 3 ELECTRICAL WIRING DIAGRAM 3 1 Circuit diagram 25QA S ...

Page 11: ... 8 3 2 Circuit diagram 35QA S ...

Page 22: ... 19 B Prevent Range I in jiggle operation from changing to Range C operation ...

Page 58: ... 55 12 Check method for outdoor unit 1 Circuit diagram of 25QA S outdoor unit ...

Page 59: ... 56 2 Circuit diagram of 35QA S outdoor unit ...

Page 81: ... 78 ...

Page 86: ... 83 RAC SRK35QA S PANEL FAN ASSY ...

Page 88: ... 85 20 21 RYD436A021 LOUVER ASSY 1 20 RYD436A020 LOUVER 12 21 RYD129A048 PLATE CONNECTING 2 ...

Page 92: ... 89 ...

Page 94: ... 91 ...

Page 98: ... ...

Page 100: ... 19 RYF937A002A CLAMP WIRE 1 ...