-69-

(1) Tools for R410A

a) Manifold pressure gauge

● As R410A has the property of high pressure, conventional tools can’t be used.

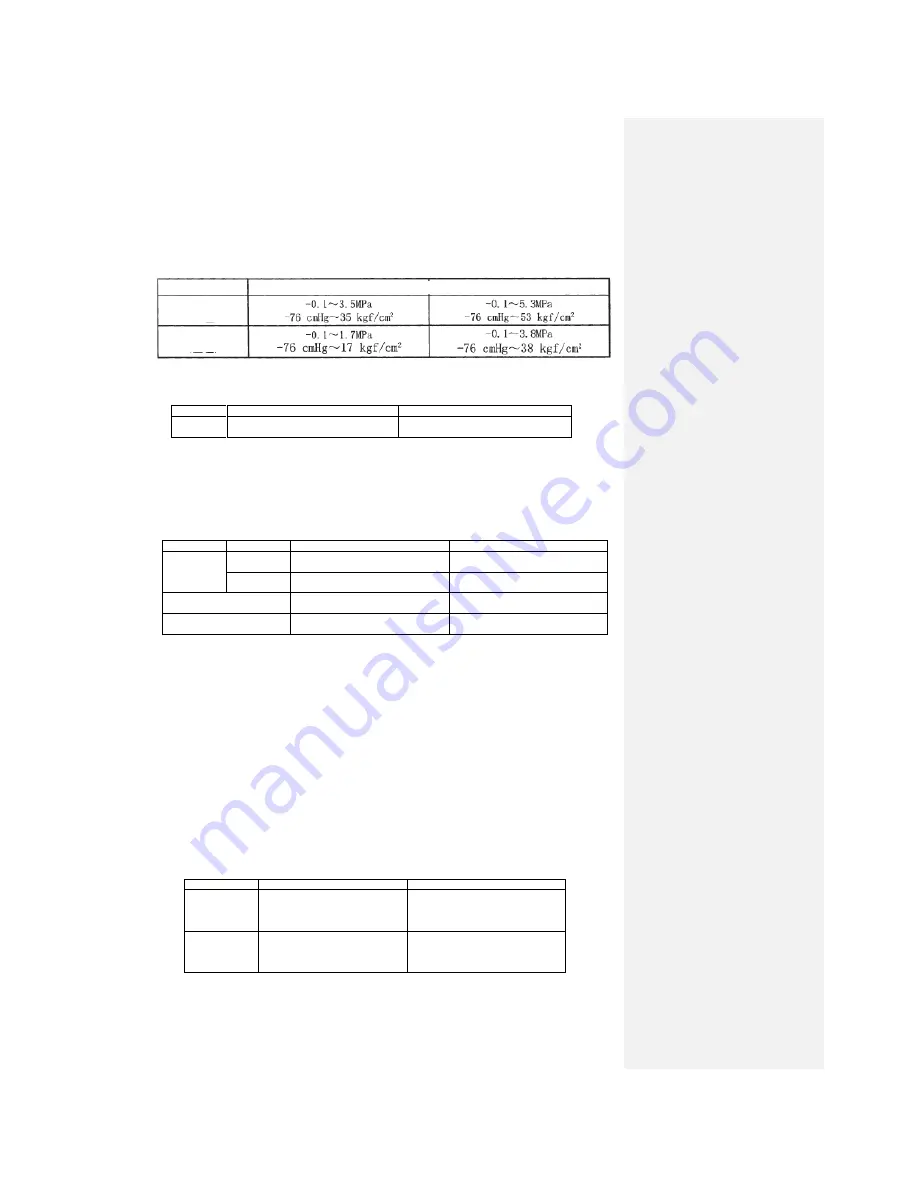

Table 11 Difference between conventional high/low pressure gauge and pressure gauge for

R410A

● In order to prevent charging other types of refrigerant accidently, the shapes of the various

ports of the branch manifold are changed.

Table 12 Difference between conventional branch manifold and branch manifold for R410A

Conventional branch manifold

Branch manifold for R410A

Port size

7/16 UNF

20 screw threads per inch

1/2 UNF

20 screw threads per inch

b) Charge hose

● Due to the property of high pressure of R410A, the pressure impedance of the charge hose

must be improved and the material is changed to HFC impedance type material.

Furthermore, in order to comply with the sizes of the various ports of the branch manifold,

the sizes of hose caps are also changed. In addition, in order to prevent gas pressure

reaction, the charge hose with a valve mounted beside the hose cap may be used.

Table 13 Difference between conventional charge hose and charge hose for R410A

Conventional charge hose

Charge hose for R410A

Pressure

impedance

Normal

pressure

3.4 MPa (34 kgf/cm

2

)

5.1 MPa (51 kgf/cm

2

)

Breakdown

pressure

17.2 MPa (172 kgf/cm

2

)

27.4 MPa (274 kgf/cm

2

)

Engineering material

NBR rubber

HNBR rubber

With nylon coating inside

Size of hose cap

7/16 UNF

20 screw threads per inch

1/2 UNF

20 screw threads per inch

c) Electronic loadcell scale for charging refrigerant

● As a kind of HFC, due to the properties of high pressure and high vapor rate, R410A can’t

keep the liquid state and foam state of pneumatolytic refrigerant in the cylinder when the

charging cylinder is used to charge R410A, and the value is difficult to read. Therefore, it

is recommended to use an electronic loadcell scale for charging refrigerant.

● The electronic loadcell scale can measure the weight of the refrigerant cylinder though the

4 supporting points, therefore it has higher strength. The connection of the charge hose has

two ports, one for R22 (7/16 UNF, 20 screw threads per inch) and one for R410A (1/2

UNF, 20 screw threads per inch), so it can be used to charge general refrigerants.

● There are two types of electronic loadcell scale for charging refrigerant, one for 10kg

cylinders and one for 20kg cylinders.

Electronic loadcell scale for 10kg cylinders precision ±2g

Electronic loadcell scale for 20kg cylinders precision ±5g

● Refrigerant can be charged manually by opening/closing the valve.

d) Torque wrench (for rating diameters of 1/2 and 5/8)

● In order to enhance the pressure impedance, the size of flare nut is changed. Therefore the

side-to-center distance of the torque wrench for R410A vary.

Table 14 Difference between conventional wrench and wrench for R410A

Conventional torque wrench

Torque wrench for R410A

For 1/2

(side-to-center

distance x

torque)

24mm x 55N · m

(550 kgf · cm)

26mm x 55N · m

(550 kgf · cm)

For 5/8

(side-to-center

distance x

torque)

27mm x 65N · m

(650 kgf · cm)

29mm x 65N · m

(650 kgf · cm)

Conventional pressure gauge

Pressure gauge designed specifically for R410A

High pressure gauge

(Red)

Compound pressure

gauge (Blue)

Summary of Contents for SRC25QA-S

Page 10: ... 7 3 ELECTRICAL WIRING DIAGRAM 3 1 Circuit diagram 25QA S ...

Page 11: ... 8 3 2 Circuit diagram 35QA S ...

Page 22: ... 19 B Prevent Range I in jiggle operation from changing to Range C operation ...

Page 58: ... 55 12 Check method for outdoor unit 1 Circuit diagram of 25QA S outdoor unit ...

Page 59: ... 56 2 Circuit diagram of 35QA S outdoor unit ...

Page 81: ... 78 ...

Page 86: ... 83 RAC SRK35QA S PANEL FAN ASSY ...

Page 88: ... 85 20 21 RYD436A021 LOUVER ASSY 1 20 RYD436A020 LOUVER 12 21 RYD129A048 PLATE CONNECTING 2 ...

Page 92: ... 89 ...

Page 94: ... 91 ...

Page 98: ... ...

Page 100: ... 19 RYF937A002A CLAMP WIRE 1 ...