-74-

(4) Recovery procedure

a) According to the instructions on refrigerant recovery device (see the operation manual

supplied), operate the device to recover refrigerant.

b) Pay attention to the following during the operation.

①

Confirm that the refrigerant recovery device runs according to the requirements and the

operation status is always monitored, so as to take correct actions in case of emergency.

②

During the operation, stay at the working site to ensure safety.

③

If you have to leave the working site due to irresistible reasons, confirm the recovery

cylinder is not over charged before stopping the operation.

c) If, during the operation, the overcharge protection of the refrigerant recovery device is

triggered and the device stops automatically, please replace with an empty recovery

cylinder.

d) If the reading of the pressure gauge increases not long after the recovery is completed and

the refrigerant recovery device stops automatically, please restart the device. If the device

stops again, end the recovery.

(5) Procedure after the recovery is completed

a) Close the valves of the air conditioner from which refrigerant has been recovered, the

refrigerant recovery device, and the recovery cylinder.

b) Disconnect the recovery cylinder for charging refrigerant and store it according to the

regulations.

7.4.2 Accessories/tools

A number of accessories/tools are used to recover R410A.

The following are standard accessories.

(1) Recovery cylinder

● Use the recovery cylinder specified by the equipment manufacturer.

● Be sure to use a removable cylinder compliant with the laws and regulations.

● Do not use a general cylinder as recovery cylinder.

Note 1: The cylinder used when R410A is bought is borrowed.

Note 2: The cylinder used when R410A is bought, which has a check valve, can’t be used

as recovery cylinder.

● Types (divided by function)

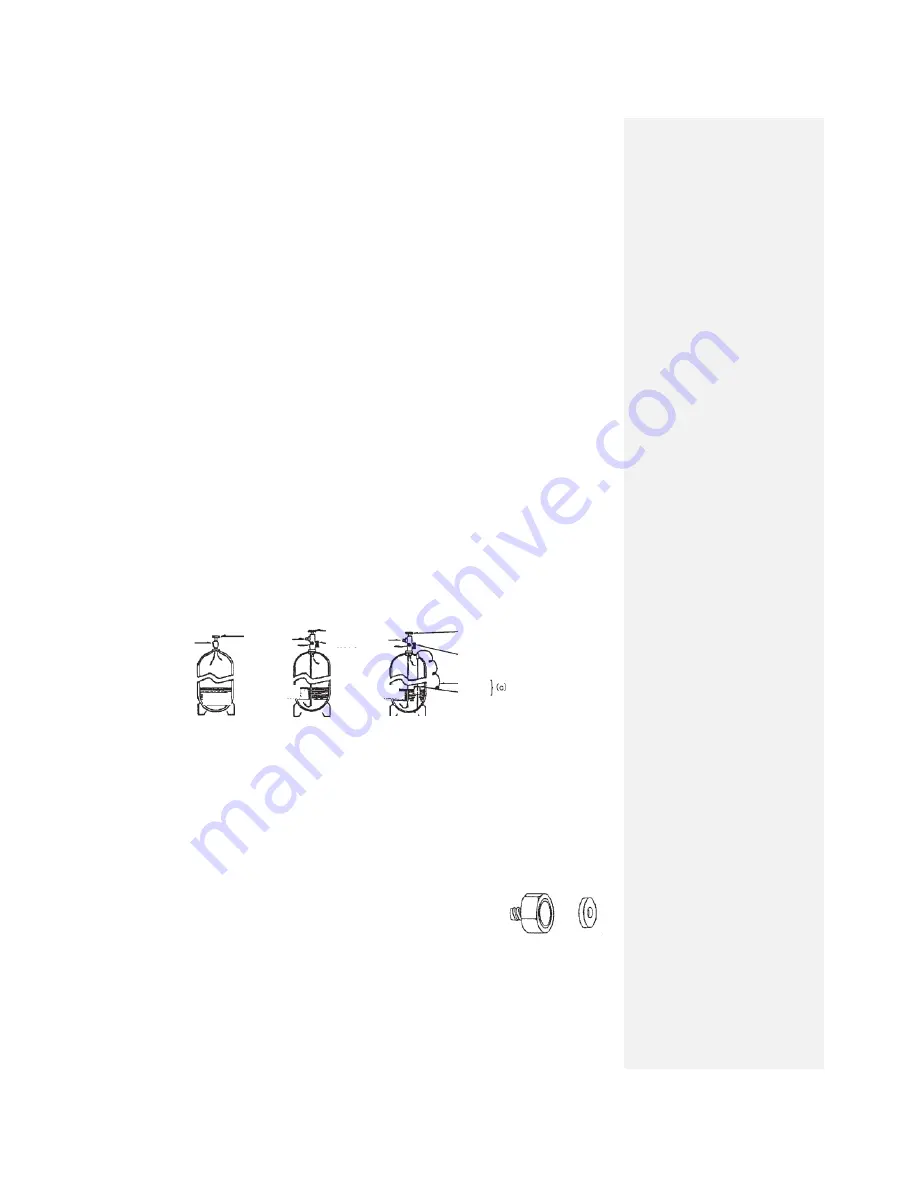

Figure 8 Types of cylinder

● Note

Laws prohibit recovery of R410A into discarded cylinders or one-way cylinders.

(2) Dryer

● A desiccant container used to remove water from R410A

●The dryer should be used as supplies.

● Before the installation, keep the dryer sealed.

● Used to protect the R410A recovery device.

(3) Connection hose

a) Charging port and charging port sealing ring

● It is generally sold separately from the refrigerant cylinder.

● The use of a two-port cylinder, which may have special

diameter, should be confirmed by the manufacturer.

● Sealing rings are supplies.

Liquid valve

Gas valve

Valve

(a) Basic type

● 1-port valve

● Suitable for R410A

recovery

●Turn it to pour out

liquid R410A.

(b) 2-port valve

● Can provide liquid

R410A or release

gas at the vertical

position.

● Easy to maintain.

Liquid

(c) Floater type

dedicated cylinder

● With a floater in it to

prevent overcharge.

Insert the conduit of the liquid valve

near the bottom of the cylinder.

Gas valve

(For releasing gas)

Signal cable

Floater

Liquid

Liquid

Charging port

Summary of Contents for SRC25QA-S

Page 10: ... 7 3 ELECTRICAL WIRING DIAGRAM 3 1 Circuit diagram 25QA S ...

Page 11: ... 8 3 2 Circuit diagram 35QA S ...

Page 22: ... 19 B Prevent Range I in jiggle operation from changing to Range C operation ...

Page 58: ... 55 12 Check method for outdoor unit 1 Circuit diagram of 25QA S outdoor unit ...

Page 59: ... 56 2 Circuit diagram of 35QA S outdoor unit ...

Page 81: ... 78 ...

Page 86: ... 83 RAC SRK35QA S PANEL FAN ASSY ...

Page 88: ... 85 20 21 RYD436A021 LOUVER ASSY 1 20 RYD436A020 LOUVER 12 21 RYD129A048 PLATE CONNECTING 2 ...

Page 92: ... 89 ...

Page 94: ... 91 ...

Page 98: ... ...

Page 100: ... 19 RYF937A002A CLAMP WIRE 1 ...