-

-

'14 • SRF-T-163

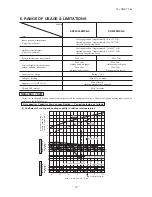

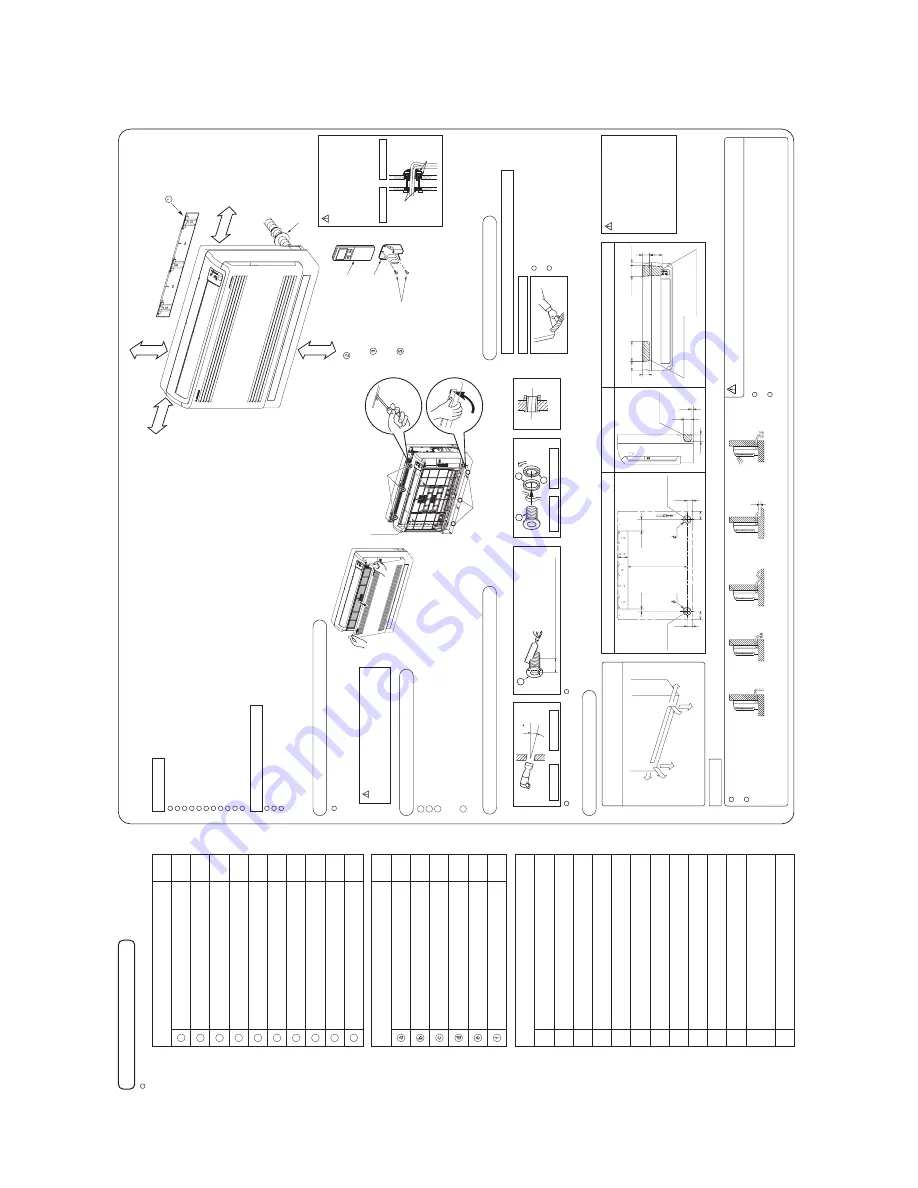

Necessary tools for the installation work

1

2

3

4

5

6

7

8

9

10

11

12

13

1

1

1

1

1

1

Q’ty

Option parts

Sealing plate

Sleeve

Inclination plate

Putty

Drain hose (extension hose)

Piping cover (for insulation of connection piping)

Plus headed driver

Knife

Saw

Tape measure

Hammer

Spanner wrench

Torque wrench

Hole core drill (65mm in diameter)

Wrench key (Hexagon) [4m/m]

Flaring tool set

Gas leak detector

Pipe bender

Gauge for projection adjustment Used when flare is made by using conventional flare tool

(

)

( )

14.0 ~ 61.0N·m (1.4 ~ 6.1kgf·m)

(

Designed specifically

for R410A

)

BEFORE INSTALLATION

R410A REFRIGERANT USED

FLOOR TYPE AIR CONDITIONER

IN

ST

AL

LA

TI

ON

M

AN

UA

L

FO

R

IN

DO

OR

U

N

IT

RFB012A007

1

1

1

9

2

2

2

2

1

2

Q’ty

Standard accessories (Installation kit)

Accessories for indoor unit

Installation board (Attached to the rear of the indoor unit)

Wireless remote control

Remote control holder

Batter

y

[R03 (AAA, Micro) 1.5V]

Air-cleaning filters

Filter holders (Attached to the front panel of indoor unit)

Pipe cover (200mm)

Tapping screws (for installation board ø4 X 25mm)

Wood screws (for remote control switch holder ø3.5 X 16mm)

1

2

3

4

5

6

7

8

9

10

Band

(

)

Designed specifically

for R410A

W

A

RNING

s

Installation must be carried out by the qualified installe

r.

If you install the system by yourself, it may cause serious t

rouble such as

water leaks, electric shocks, fi

re and personal injur

y, as a

result of a system

malfunction. Do not carry out the installation and maintenance work except

the by qualified installe

r.

s

Install the system in full acco

rdance with the installation manual.

Incor

rect installation may cause bursts, personal injur

y, water leaks, electric

shocks and fi

re.

s

Be su

re to use only for household and

residence.

If this appliance is installed in inferior envi

ronment such as machine shop

and etc., it can cause malfunction.

s

Use the original accessories and the specified components for

installation.

If parts other than those p

rescribed by us a

re used, It may cause water

leaks, electric shocks, fi

re and personal injury.

s

Install the unit in a location with good support.

Unsuitable installation locations can cause the unit to fall and cause

material damage and personal injury.

s

Ventilate the working a

rea well in the event of

refrigerant leakage

during installation.

If the

refrigerant comes into contact with naked flames, poisonous gas is

pr

oduced.

s

When installing in small

rooms, take p

revention measu

res not to

exceed the density limit of

refrigerant in the event of leakage,

refer

red by the formula (acco

rdance with ISO5149).

If the density of

refrigerant exceeds the limit, please consult the dealer and

install the ventilation system, otherwise lack of oxygen can occu

r, which

can cause serious accident.

s

After completed installation, check that no

refrigerant leaks f

rom

the system.

If

refrigerant leaks into the

room and comes into contact with an oven or

other hot surface, poisonous gas is p

roduced.

s

Use the p

rescribed pipes, fla

re nuts and tools for R410A.

Using existing parts (for R22 or R407C) can cause the unit failu

re and

serious accidents due to burst of the

refrigerant ci

rcuit.

s

Tighten the fla

re nut by to

rque w

rench with specified method.

If the fla

re nut we

re tightened with excess to

rque, this may cause burst and

refrigerant leakage after a long period.

s

The electrical installation must be carried out by the qualified

electrician in acco

rdance with “the norm for electrical work” and

“national wiring

regulation”, and the system must be connected to

the dedicated ci

rcuit.

Power supply with insu

fficient capacity and incor

rect function done by

imp

roper work can cause electric shocks and fi

re.

s

Be su

re to shut o

ff the power befo

re starting electrical work.

Failu

re to shut o

ff the power can cause electric shocks, unit failu

re or

incor

rect function of equipment.

s

Be su

re to use the cables conformed to safety standa

rd and cable

ampacity for power distribution work.

Unconformable cables can cause electric leak, anomalous heat p

roduction

or fi

re.

s

This appliance must be connected to main power supply by means

of a ci

rcuit b

reaker or switch (fuse:16A) with a contact separation of

at least 3mm.

s

When plugging this appliance, a plug conforming to the norm

IEC60884-1 must be used.

s

Use the p

rescribed cables for electrical connection, tighten the

cables secu

rely in terminal block and

relieve the cables cor

rectly to

p

revent overloading the terminal blocks.

Loose connections or cable mountings can cause anomalous heat

pr

oduction or fi

re.

s

Arrange the wiring in the cont

rol box so that it cannot be pushed up

further into the box. Install the service panel cor

rectly.

Incor

rect installation may

result in overheating and fi

re.

s

Be su

re to switch o

ff the power supply in the event of installation,

inspection or servicing.

If the power supply is not shut o

ff, the

re is a risk of electric shocks, unit

failu

re or personal injury due to the unexpected start of fan.

s

Be su

re to wear p

rotective goggles and gloves while at work.

s

Earth leakage b

reaker must be installed.

If the earth leakage b

reaker is not installed, it can cause electric shocks.

CAUTION

s

Use the ci

rcuit b

reaker of cor

rect capacity. Ci

rcuit b

reaker should

be the one that disconnect all poles under over cur

rent.

Using the incor

rect one could cause the system failu

re and fi

re.

s

Install isolator or disconnect switch on the power supply wiring in

acco

rdance with the local codes and

regulations.

The isolator should be locked in OFF state in acco

rdance with EN60204-1.

s

Be su

re to install indoor unit p

roperly acco

rding to the installation

manual in o

rder to run o

ff the drainage smoothly.

Imp

roper installation of indoor unit can cause d

ropping water into the

room

and damaging personal p

roperty.

s

Install the drainage pipe to run o

ff drainage secu

rely acco

rding to

the installation manual.

Incor

rect installation of the drainage pipe can cause d

ropping water into the

room and damaging personal p

roperty.

s

Be su

re to install the drainage pipe with descending slope of 1/100

or mo

re, and not to make traps and ai

r-bleedings.

Check if the drainage runs o

ff secu

rely during commissioning and ensu

re

the space for inspection and maintenance.

s

Secu

re a space for installation, inspection and maintenance

specified in the manual.

Insu

fficient space can

result in accident such as personal injury due to

falling f

rom the installation place.

s

For installation work, be ca

reful not to get inju

red with the heat

exchange

r, piping fla

re portion or sc

rews etc.

s

Be su

re to insulate the

refrigerant pipes so as not to condense the

ambient air moistu

re on them.

Insu

fficient insulation can cause condensation, which can lead to moistu

re

damage on the ceiling, floo

r, fu

rnitu

re and any other valuables.

s

W

he

n

p

er

fo

rm

t

he

a

ir

c

o

nd

iti

o

ne

r

o

p

er

at

io

n

(c

o

o

lin

g

o

r

d

ry

in

g

o

p

er

a-

tio

n)

in

w

hi

ch

v

en

til

at

o

r

is

in

st

al

le

d

in

t

he

r

o

o

m

. I

n

th

is

c

as

e,

u

si

ng

t

he

ai

r

co

nd

iti

o

ne

r

in

p

ar

al

le

lw

ith

th

e

ve

nt

ila

to

r,

th

er

e

is

th

e

p

o

ss

ib

ili

ty

th

at

d

ra

in

w

at

er

m

ay

b

ac

kf

lo

w

in

a

cc

o

rd

an

ce

w

ith

t

he

r

o

o

m

la

p

se

in

to

th

e

ne

g

at

iv

e

pr

es

su

re

s

ta

tu

s.

T

he

re

fo

re

, s

et

u

p

t

he

o

p

en

in

g

p

o

rt

s

uc

h

as

in

co

rp

o

ra

te

t

he

a

ir

in

to

t

he

r

o

o

m

t

ha

t

m

ay

a

p

p

ro

p

ri

at

e

to

v

en

til

a-

tio

n

(F

or

e

xa

m

p

le

; O

p

en

t

he

d

o

o

r

a

lit

tle

).

In

a

d

d

iti

o

n,

ju

st

a

s

ab

o

ve

, s

o

se

t

up

t

he

o

p

en

in

g

p

o

rt

if

t

he

r

o

o

m

la

p

se

in

to

n

eg

at

iv

e

p

re

ss

ur

e

st

at

us

d

ue

t

o

r

eg

is

te

r

o

f t

he

w

in

d

fo

r

th

e

hi

g

h

ri

se

a

p

ar

tm

en

t

et

c.

s

Be su

re to perform air tightness test by p

ressurizing with nit

rogen

gas after completed

refrigerant piping work.

If the density of

refrigerant exceeds the limit in the event of

refrigerant

leakage in the small

room, lack of oxygen can occu

r, which can cause

serious accidents.

s

Do not install the unit in the locations listed belo

w

.

t

Locations whe

re carbon fibe

r, metal powder or any powder is floating.

t

Locations whe

re any substances that can a

ffect the unit such as sulphide

gas, chloride gas, acid and alkaline can occu

r.

t

Vehicles and ships.

t

Locations whe

re cosmetic or special sprays a

re often used.

t

Locations with di

rect exposu

re of oil mist and steam such as kitchen and

machine plant.

t

Locations whe

re any machines which generate high f

requency harmonics

ar

e used.

t

Locations with salty atmosphe

res such as coastlines.

t

Locations with heavy snow (If installed, be su

re to p

rovide base flame and

snow hood mentioned in the manual).

t

Locations whe

re the unit is exposed to chimney smoke.

t

Locations at high altitude (mo

re than 1000m high).

t

Locations with ammonic atmosphe

res.

t

Locations whe

re heat radiation f

rom other heat sou

rce can a

ffect the unit.

t

Locations without good air ci

rculation.

t

Lo

ca

tio

ns

w

ith

an

y

ob

st

ac

le

s

w

hi

ch

ca

n

pr

ev

en

ti

nl

et

an

d

ou

tle

ta

ir

of

th

e

un

it.

t

Locations whe

re short ci

rcuit of air can occur (in case of multiple units

installation).

t

Locations whe

re st

rong air blows against the air outlet of outdoor unit.

t

Locations whe

re something located above the unit could fall.

It can cause

remarkable dec

rease in performance, cor

rosion and damage

of components, malfunction and fi

re.

s

Do not install the indoor unit in the locations listed below (Be su

re

to install the indoor unit acco

rding to the installation manual for

each model because each indoor unit has each limitation).

t

Locations with any obstacles which can p

revent inlet and outlet air of the

unit.

t

Locations whe

re vibration can be amplified due to insu

fficient st

rength of

structu

re.

t

Locations whe

re the infra

red

receiver is exposed to the di

rect sunlight or

the st

rong light beam (in case of the infra

red specification unit).

t

Locations whe

re an equipment a

ffected by high harmonics is placed (TV

set or radio

receiver is placed within 1m).

t

Locations whe

re drainage cannot run o

ff safely.

It can a

ffect performance or function and etc.

s

Do not install the unit near the location whe

re leakage of

combustible gases can occu

r.

If leaked gases accumulate a

round the unit, it can cause fi

re.

s

Do not install the unit whe

re cor

rosive gas (such as sulfu

rous acid

gas etc.) or combustible gas (such as thinner and pet

roleum gases)

can accumulate or collect, or whe

re volatile combustible

substances a

re handled.

Cor

rosive gas can cause cor

rosion of heat exchange

r, b

reakage of plastic

parts and etc. And combustible gas can cause fi

re.

s

Do not use the indoor unit at the place whe

re water splashes may

occur such as in laundries.

Since the indoor unit

is n

ot

w

at

erp

ro

of,

it

can

caus

e

el

ectr

ic

sho

cks

and fi

re

.

s

Do not install nor use the system close to the equipment that

generates elect

romagnetic fields or high f

requency harmonics.

Equipment such as inverters, standby generators, medical high f

requency

equipments and telecommunication equipments can a

ffect the system, and

cause malfunctions and b

reakdowns. The system can also a

ffect medical

equipment and telecommunication equipment, and obstruct its function or

cause jamming.

s

Do not place any variables which will be damaged by getting wet

under the indoor unit.

When the

relative humidity is higher than 80% or drainage pipe is clogged,

condensation or drainage water can d

rop and it can cause the damage of

valuables.

s

Do not install the wireless

remote cont

rol at the di

rect sunlight.

It can cause malfunction or deformation of the wireless

remote cont

rol.

s

Do not use the unit for special purposes such as storing foods,

cooling p

recision instruments and p

reservation of animals, plants or

art.

It can cause the damage of the items.

s

Do not use any materials other than a fuse with the cor

rect rating in

the location whe

re fuses a

re to be used.

Connecting the ci

rcuit with copper wi

re or other metal th

read can cause

unit failu

re and fi

re.

s

Do not touch any buttons with wet hands.

It can cause electric shocks.

s

Do not touch any

refrigerant pipes with your hands when the

system is in operation.

During operation the

refrigerant pipes become ext

remely hot or ext

remely

cold depending the operating condition, and it can cause bu

rn injury or

frost injury.

s

Carry out the electrical work for g

round lead with ca

re.

Do not connect the g

round lead to the gas line, water line, lightning conductor or telephone line

’s g

round lead. Incor

rect g

ro

unding can cause unit faults

such as electric shocks due to short-ci

rcuiting.

s

Do not put the drainage pipe di

rectly into drainage channels whe

re

poisonous gases such as sulphide gas can occu

r.

Poisonous gases will flow into the

room th

rough drainage pipe and

seriously a

ffect the user

’s health and safety. This can also cause the

cor

rosion of the indoor unit and a

resultant unit failu

re or

refrigerant leak.

s

Ensu

re that no air enters in the

refrigerant ci

rcuit when the unit is

installed and

removed.

If air enters in the

refrigerant ci

rcuit, the p

ressu

re in the

refrigerant ci

rcuit

becomes too high, which can cause burst and personal injury.

s

Do not p

rocessing, splice the power co

rd, or sha

re a socket with

other power plugs.

This may cause fi

re or electric shock due to defecting contact, defecting

insulation and ove

r-cur

rent etc.

s

Do not bundling, winding or p

rocessing for the power co

rd. O

r, do

not deforming the power plug due to t

read it.

This may cause fi

re or heating.

s

Do not vent R410A into the atmosphe

re : R410A is a fluorinated

g

reenhouse gas, cove

red by the Kyoto P

rotocol with G

roval

W

arming Potential (GWP)=1975.

s

Do not run the unit with

removed panels or p

rotections.

Touching

rotating equipments, hot surfaces or high voltage parts can cause

personal injury due to entrapment, bu

rn or electric shocks.

s

Do not perform any change of p

rotective device itself or its setup

condition.

The fo

rced operation by short-ci

rcuiting p

rotective device of p

ressu

re

switch and temperatu

re cont

roller or the use of non specified component

can cause fi

re or burst.

W

A

RNING

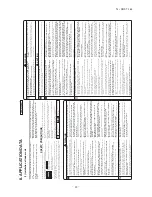

SAFETY PRECAUTIONS

t

Read the “SAFETY PRECAUTIONS” ca

refully first of all and strictly follow it

during the installation work in o

rder to p

rotect yourself.

t

The p

recautionary items mentioned below a

re distinguished into two levels,

and .

:

W

rong installation would cause serious consequences such

as injuries or death.

:

W

rong installation might cause serious consequences

depending on ci

rcumstances.

Both mentions the important items to p

rotect your health and safety so strictly

follow them by any means.

t

B

e

su

re

to

co

nf

irm

no

an

om

al

y

on

th

e

eq

ui

pm

en

t

by

co

m

m

is

si

on

in

g

af

te

r

co

m

-

pl

et

ed

in

st

al

la

tio

n

an

d

ex

pl

ai

n

th

e

op

er

at

in

g

m

et

ho

ds

as

w

el

la

s

th

e

m

ai

nt

en

an

ce

m

et

ho

ds

of

th

is

eq

ui

pm

en

tt

o

th

e

us

er

a

cc

or

di

ng

to

th

e

ow

ne

r’s

m

an

ua

l.

t

Keep the installation manual together with owner

’s manual at a place whe

re

any user can

read at any time. Mo

reover if necessar

y, ask to hand them to a

new use

r.

t

For installing qualified personnel, take p

recautions in

respect to themselves by

using suitable p

rotective clothing, g

roves, etc., and then perform the

installation works.

t

Please pay attention not to fall down the tools, etc. when installing the unit at

the high position.

t

If unusual noise can be hea

rd during operation, consult the deale

r.

t

The meanings of “Marks” used he

re a

re shown as follows:

Never do it under any

ci

rcumstances.

Always do it acco

rding to the

instruction.

CAUTION

W

A

RNING

CAUTION

W

A

RNING

s

This installation manual illustrates the method of installing an indoor

unit.

s

For electrical wiring work, please see instructions set out on the

backside.

s

For outdoor unit installation and

refrigerant piping, please

refer to

page 26

s

A wi

red

remote cont

rol unit is supplied separately as an optional part.

s

When install the unit, be su

re to check whether the selection of

installation place, power supply specifications, usage limitation (piping

length, height di

ffe

rences between indoor and outdoor units, power

supply voltage and etc.) and installation spaces.

Befo

re installation check that the power supply matches the air conditione

r.

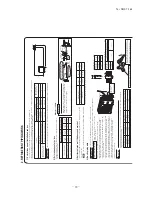

Right

Rear

Downwa

rd

Left

rear

Left downwa

rd

Left

60

15

60

60

22.7

85.3

100

55

157.2

76.3

For Right or Left

rear pipin

g

For Right or Left piping

Right/Left piping

For Right or Left bottom piping

Left bottom piping

Right bottom piping

SELECTION OF INS

TALL

A

TION LOC

A

TION

INS

TALL

A

TION OF INDOOR UNIT

Indoor unit

Installing the support of piping

(Install at location that meets the following conditions, after getting app

roval f

rom the customer)

Wi

reless

remote cont

rol

In case of piping in the right

rear di

rection

When drilling the wall that contains a metal lath, wi

re lath or metal plate, be su

re to use pipe hole sleeve sold separately.

Taping of the exterior

Top

Thicknese of the wall + 1.5cm

5

ø65

In

d

oo

r s

id

e

O

ut

d

oo

rs

id

e

In

d

oo

rs

id

e

O

ut

d

oo

r s

id

e

Installed state

Tu

rn

to

tighten

b

b

c

a

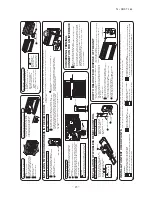

Open and detachment of the air inlet panel

Drilling of holes and fixtu

re of sleeve (Option parts)

How to

remove the f

ront panel

Indoor unit piping di

rection

CAUTION

Drainage

The drain hose

tip is in water

Higher than

specified

W

avy

The gap to the g

round

is 5 cm or less

The drain hose tip

is in the gutter

Odor f

rom

the gutter

Whe

re the

re is no obstructions to the air flow and whe

re the cooled and heated air can be evenly distributed.

A solid place whe

re the unit or the wall will not vibrate.

A place whe

re the

re will be enough space for servicing. (Whe

re space mentioned below can be secu

red)

Whe

re wiring and the piping work will be easy to conduct.

The place whe

re

receiving part is not exposed to the di

rect rays of the sun or the st

rong rays of the st

reet lighting.

A place whe

re it can be easily drained.

A place separated at least 1m away f

rom the television or the radio. (

To p

revent interfe

rence to images and sounds.)

Places whe

re this unit is not a

ffected by the high f

requency equipment or electric equipment.

A

void installing this unit in place whe

re the

re is much oil mist.

Places whe

re the

re is no electric equipment or household under the installing unit.

Install the indoor unit on flat wall.

A place whe

re the air conditioner can be

received the signal su

rely during operating the wi

reless

remote cont

rol.

Places whe

re the

re is no a

ffected by the TV and radio etc.

Do not place whe

re exposed to di

rect sunlight or near heat devices such as a stove.

To

open, pull the panel at both ends of upper

part and

release latches, and undo the strings.

Then

remove the panel.

When

removing the ai

r-inlet panel, be

ca

reful not to d

rop it on your feet.

CAUTION

Remove the air inlet panel.

Remove the 5 set sc

rews.

Remove the 3 latches in the upper section.

If the latches a

re di

fficult to

remove, push the latch portion out using a sc

rew

drive

r, for example.

Move the lower part of the panel forwa

rd and

remove the 6 latches in the

under section.

1

2

3

4

Wi

reless

remote cont

rol

Remote cont

rol holder

W

ood sc

rews

Installation boa

rd

5 cm minimum

fr

om the wall

5

cm

+ Ser

vice

space

(3

0c

m

)

fr

om

the

wall

7 cm minimum f

rom the ceiling

15 cm or below

fr

om the floor

Sleeve (sold separately)

C

A

UTION

putty

putty

Indoor side

Outdoor side

Completely seal the hole

on the

w

all with putt

y.

Otherwis

e, fu

rnitur

e, or

othe

r, m

ay be

w

etted

b

y

lea

ked

w

ater or d

ewing.

C

A

UTION

Be ca

reful not to st

ress the

connecting

refrigerant

pipse. (Do not pull with a

fo

rce of larger than 5 kgf.)

If imp

roperly installed, it

may cause abnormal noise

and vibration.

Latch

Latch

The sc

rew of the lid is tightened secu

rely.

Drill a hole with whole co

re drill

.

In case of

rear piping draw out, cut o

ff the lower

and the right side portions of the sleeve colla

r.

18.5

91.5

45

65

65

65

470

80

65

45

Right

rear

piping

Left

rear

piping

Piping is possible in the rear, left, left rear,

left downward, right or downward direction.

Tape only the portion that goes through

the wall.

Always tape the wiring with the piping.

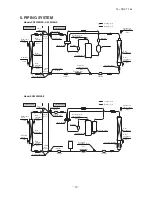

A

rr

an

ge

th

e

d

ra

in

h

os

e

in

a

d

ow

nw

ar

d

an

gl

e.

A

void the following

drain piping.

Pour water to the drain pan located under the heat exchange

r, and ensu

re that

the water is discharged outdoo

r.

When the extended drain hose is indoo

r, secu

rely insulate it with a heat insulator

available in the market.

Su

fficient ca

re

m

ust be ta

ken not to damage

the panel when connecting pipe

s.

Go th

rough all installation steps and check if the dralnage is all right.

Otherwise water leak may occu

r.

Summary of Contents for SRF25ZMXA-S

Page 2: ......

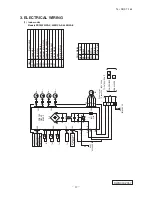

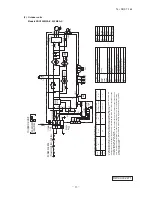

Page 3: ... 14 SRF T 163 TECHNICAL MANUAL ...

Page 12: ... 10 14 SRF T 163 3 Remote control Unit mm 60 26 167 a Wireless remote control ...

Page 93: ... 91 14 SRF T 163 WARING CAUTION 3 Super link E board SC ADNA E F ...

Page 94: ... 92 14 SRF T 163 ...

Page 100: ... 98 14 SRF T 163 CRCE0010 12 13 14 3 2 1 4 4 5 10 10 4 7 8 9 6 15 16 11 CONTROL PARTS SET ...

Page 106: ... 104 14 SRF T 163 CRCE0010 12 13 14 3 2 1 4 4 5 10 10 4 7 8 9 6 15 16 11 CONTROL PARTS SET ...

Page 112: ... 110 14 SRF T 163 CRCE0010 12 13 14 3 2 1 4 4 5 10 10 4 7 8 9 6 15 16 11 CONTROL PARTS SET ...

Page 114: ... 112 14 SRF T 163 CRBE0276 6 13 11 12 15 16 3 17 14 2 4 9 8 7 5 1 8 8 10 PANEL FAN ASSY ...

Page 118: ... 116 14 SRF T 163 CRBE0276 6 13 11 12 15 16 3 17 14 2 4 9 8 7 5 1 8 8 10 PANEL FAN ASSY ...

Page 122: ... 120 14 SRF T 163 CRBE0315 9 13 15 16 14 17 7 6 4 1 8 3 11 5 18 10 10 10 2 12 PANEL FAN ASSY ...