-

-

'14 • SRF-T-163

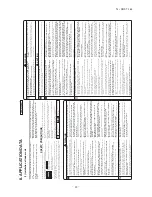

Accessories for outdoor unit

• Model name and power source

• Refrigerant piping length

• Piping, wiring and miscellaneous small parts

• Indoor unit installation manual

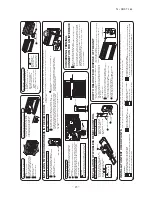

Necessary tools for the installation work

Wrench key (Hexagon) [4m/m]

Vacuum pump

Vacuum pump adapter (Anti-reverse flow type)

(Designed specifically for R410A)

Gauge manifold (Designed specifically for R410A)

Charge hose (Designed specifically for R410A)

Flaring tool set (Designed specifically for R410A)

Gas leak detector (Designed specifically for R410A)

Gauge for projection adjustment

(Used when flare is made by using conventional flare tool)

9

10

11

12

13

14

15

16

Plus headed driver

Knife

Saw

Tape measure

Hammer

Spanner wrench

Torque wrench [14.0

~

62.0N·m (1.4

~

6.2kgf·m)]

Hole core drill (65mm in diameter)

1

2

3

4

5

6

7

8

Grommet (Heat pump type only)

Drain elbow (Heat pump type only)

Q’ty

4

1

1

2

Option parts

Sealing plate

Sleeve

Inclination plate

Putty

Drain hose (extension hose)

Piping cover

(for insulation of connection piping)

Q’ty

1

1

1

1

1

1

Check befor

e installation work

a

b

c

d

e

f

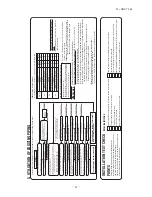

CAUTION

•

Car

ry out the electrical work for ground lead with care.

Do not connect the ground lead to the gas line, water line, lightning conductor or telephone line

’s ground lead. Incorrect gro

unding can cause unit faults such as electric shocks due to short-circuiting.

•

Use the circuit breaker for all pole correct capacity. Circuit breaker should be the one that disconnect all poles under over current.

Using the incorrect circuit breake

r, it can cause the unit malfunction and fire.

•

Install isolator or disconnect switch on the power supply wiring in accordance with the local codes and regulations.

The isolator should be locked in OFF state in accordance with EN60204-1.

•

Af

te

r m

ai

nt

en

an

ce

, a

ll

w

iri

ng

, w

iri

ng

tie

s

an

d

th

e

lik

e,

sh

ou

ld

b

e

re

tu

rn

ed

to

th

ei

r o

rig

in

al

s

ta

te

a

nd

w

iri

ng

ro

ut

e,

a

nd

th

e

ne

ce

ss

ar

y

cl

ea

ra

nc

e

fro

m

al

l m

et

al

pa

rts

s

ho

ul

d

be

s

ec

ur

ed

.

•

Se

cu

re

a

sp

ac

e

fo

r i

ns

ta

lla

tio

n,

in

sp

ec

tio

n

an

d

m

ai

nt

en

an

ce

s

pe

ci

fie

d

in

th

e

m

an

ua

l.

Insufficient space can result in accident such as personal inju

ry due to falling from

the installation place.

•

Take care when car

rying the unit by hand.

If the unit weights more than 20kg, it must be carried by two or more persons. Do not car

ry by the plastic straps, always use the car

ry handle when car

rying the unit

by hand. Use gloves to minimize the risk of cuts by the aluminum fins.

•

Dispose of any packing materials correctly.

Any remaining packing materials can cause personal inju

ry as it contains nails and

wo

od

.A

nd

to

av

oi

d

da

ng

er

o

fs

uf

fo

ca

tio

n,

be

su

re

to

ke

ep

th

e

pl

as

tic

wr

ap

pe

r

aw

ay

fr

om

c

hi

ld

re

n

an

d

to

d

is

po

se

a

fte

r t

ea

r i

t u

p.

•

Be sure to insulate the refrigerant pipes so as not to condense the ambient air moisture on them.

In

su

ffi

ci

en

t i

ns

ul

at

io

n

ca

n

ca

us

e

co

nd

en

sa

tio

n,

w

hi

ch

c

an

le

ad

to

m

oi

st

ur

e

da

m

ag

e

on

th

e

ce

ili

ng

,f

lo

or

,f

ur

ni

tu

re

an

d

an

y

ot

he

rv

al

ua

bl

es

.

•

W

he

n

pe

rfo

rm

th

e

ai

r c

on

di

tio

ne

r o

pe

ra

tio

n

(c

oo

lin

g

or

dr

yi

ng

o

pe

ra

tio

n)

in

w

hi

ch

ve

nt

ila

to

r i

s

in

st

al

le

d

in

th

e

ro

om

. I

n

th

is

ca

se

, u

si

ng

th

e

ai

r

co

nd

iti

on

er

in

p

ar

al

le

l w

ith

th

e

ve

nt

ila

to

r,

th

er

e

is

th

e

po

ss

ib

ili

ty

th

at

dr

ai

n

w

at

er

m

ay

b

ac

kf

lo

w

in

a

cc

or

da

nc

e

w

ith

th

e

ro

om

la

ps

e

in

to

th

e

ne

ga

tiv

e

pr

es

su

re

s

ta

tu

s.

T

he

re

fo

re

,s

et

up

th

e

op

en

in

g

po

rt

su

ch

as

in

co

rp

or

at

e

th

e

ai

r i

nt

o

th

e

ro

om

th

at

m

ay

a

pp

ro

pr

ia

te

to

v

en

til

at

io

n

(F

or

ex

am

pl

e;

Op

en

th

e

do

or

a

lit

tle

).

In

a

dd

iti

on

, j

us

ta

s

ab

ov

e,

s

o

se

tu

p

th

e

op

en

in

g

po

rt

if

th

e

ro

om

la

ps

e

in

to

n

eg

at

iv

e

pr

es

su

re

st

at

us

du

e

to

re

gi

st

er

o

ft

he

w

in

d

fo

r t

he

h

ig

h

ris

e

ap

ar

tm

en

te

tc

.

•

Do

n

ot

in

st

al

l t

he

u

ni

t i

n

th

e

lo

ca

tio

ns

li

ste

d

be

lo

w

.

•

Lo

ca

tio

ns

wh

er

ec

ar

bo

n

fib

er,

m

eta

lp

ow

de

ro

ra

ny

po

wd

er

is

flo

ati

ng

.

•

Lo

ca

tio

ns

w

he

re

an

y s

ub

sta

nc

es

th

at

ca

n

aff

ec

t t

he

u

ni

t s

uc

h

as

su

lp

hi

de

g

as

,

ch

lo

rid

e g

as

, a

cid

an

d

alk

ali

ne

ca

n

oc

cu

r.

•

Ve

hi

cle

s a

nd

sh

ip

s.

•

Lo

ca

tio

ns

w

he

re

co

sm

eti

c o

r s

pe

cia

l s

pr

ay

s a

re

o

fte

n

us

ed

.

•

Lo

ca

tio

ns

w

ith

di

re

ct

ex

po

su

re

of

oi

lm

ist

an

d

ste

am

su

ch

as

kit

ch

en

an

d

m

ac

hi

ne

p

lan

t.

•

Lo

ca

tio

ns

w

he

re

an

ym

ac

hi

ne

sw

hi

ch

ge

ne

ra

te

hi

gh

fre

qu

en

cy

ha

rm

on

ics

ar

e

us

ed

.

•

Lo

ca

tio

ns

w

ith

sa

lty

at

m

os

ph

er

es

su

ch

as

co

as

tli

ne

s.

•

Lo

ca

tio

ns

w

ith

he

av

ys

no

w

(If

in

sta

lle

d,

be

su

re

to

pr

ov

id

eb

as

ef

lam

ea

nd

sn

ow

ho

od

m

en

tio

ne

d

in

th

em

an

ua

l).

•

Lo

ca

tio

ns

w

he

re

th

e u

ni

t i

s e

xp

os

ed

to

ch

im

ne

y s

m

ok

e.

•

Lo

ca

tio

ns

at

hi

gh

alt

itu

de

(m

or

et

ha

n

10

00

m

hi

gh

).

•

Lo

ca

tio

ns

w

ith

am

m

on

ic

atm

os

ph

er

es

.

•

Lo

ca

tio

ns

w

he

re

h

ea

t r

ad

iat

io

n

fro

m

o

th

er

h

ea

t s

ou

rc

e c

an

af

fec

t t

he

u

ni

t.

•

Lo

ca

tio

ns

w

ith

ou

t g

oo

d

air

ci

rc

ul

ati

on

.

•

Lo

ca

tio

ns

w

ith

an

y o

bs

tac

les

w

hi

ch

ca

n

pr

ev

en

t i

nl

et

an

d

ou

tle

t a

ir

of

th

e u

ni

t.

•

Lo

ca

tio

ns

w

he

re

sh

or

tc

irc

ui

to

fa

ir

ca

n

oc

cu

r (

in

ca

se

of

m

ul

tip

le

un

its

in

sta

lla

tio

n)

.

•

Lo

ca

tio

ns

w

he

re

str

on

g

air

bl

ow

sa

ga

in

st

th

ea

ir

ou

tle

to

fo

ut

do

or

un

it.

•

Lo

ca

tio

ns

w

he

re

so

m

eth

in

g

lo

ca

ted

ab

ov

e t

he

u

ni

t c

ou

ld

fa

ll.

It

ca

n

ca

us

e r

em

ar

ka

bl

e d

ec

re

as

e i

n

pe

rfo

rm

an

ce

, c

or

ro

sio

n

an

d

da

m

ag

e o

f

co

m

po

ne

nt

s,

m

alf

un

cti

on

an

d

fir

e.

•

Do

n

ot

in

st

al

l t

he

o

ut

do

or

un

it

in

th

e

lo

ca

tio

ns

lis

te

d

be

lo

w

.

•

Lo

ca

tio

ns

wh

er

ed

isc

ha

rg

ed

ho

ta

ir

or

op

er

ati

ng

so

un

d

of

th

eo

ut

do

or

un

it

ca

n

bo

th

er

n

eig

hb

or

ho

od

.

•

Lo

ca

tio

ns

wh

er

eo

ut

let

air

of

th

eo

ut

do

or

un

it

bl

ow

sd

ire

ctl

yt

o

an

an

im

al

or

pl

an

ts.

Th

eo

ut

let

air

ca

n

aff

ec

ta

dv

er

se

ly

to

th

ep

lan

te

tc.

•

Lo

ca

tio

ns

wh

er

ev

ib

ra

tio

n

ca

n

be

am

pl

ifi

ed

an

d

tra

ns

m

itt

ed

du

et

o

in

su

ffi

cie

nt

str

en

gt

h

of

st

ru

ctu

re

.

•

Lo

ca

tio

ns

wh

er

ev

ib

ra

tio

n

an

d

op

er

ati

on

so

un

d

ge

ne

ra

ted

by

th

eo

ut

do

or

un

it

ca

n

aff

ec

ts

er

io

us

ly

(o

n

th

ew

all

or

at

th

ep

lac

en

ea

rb

ed

ro

om

).

•

Lo

ca

tio

ns

wh

er

ea

n

eq

ui

pm

en

ta

ffe

cte

d

by

hi

gh

ha

rm

on

ics

is

pl

ac

ed

(T

V

se

to

r

ra

di

o

re

ce

ive

ri

sp

lac

ed

w

ith

in

5m

).

•

Lo

ca

tio

ns

wh

er

ed

ra

in

ag

ec

an

no

tr

un

of

fs

afe

ly.

It

ca

n

aff

ec

t s

ur

ro

un

di

ng

en

vir

on

m

en

t a

nd

ca

us

e a

cl

aim

.

•

Do

n

ot

in

st

al

l t

he

u

ni

t n

ea

r t

he

lo

ca

tio

n

w

he

re

le

ak

ag

e

of

c

om

bu

st

ib

le

ga

se

s

ca

n

oc

cu

r.

If

lea

ke

d

ga

se

s a

cc

um

ul

ate

ar

ou

nd

th

e u

ni

t,

it

ca

n

ca

us

e f

ire

.

•

Do

no

t i

ns

ta

ll

th

e

un

it

w

he

re

co

rr

os

iv

e

ga

s

(s

uc

h

as

su

lfu

ro

us

a

ci

d

ga

s

et

c.

)

or

c

om

bu

st

ib

le

ga

s

(s

uc

h

as

th

in

ne

r a

nd

p

et

ro

le

um

ga

se

s)

ca

n

ac

cu

m

ul

at

e

or

c

ol

le

ct

,o

rw

he

re

vo

la

til

e

co

m

bu

st

ib

le

s

ub

st

an

ce

s

ar

e

ha

nd

le

d.

Co

rro

si

ve

ga

s

ca

n

ca

us

e

co

rro

si

on

of

he

at

ex

ch

an

ge

r,

br

ea

ka

ge

of

pl

as

tic

pa

rts

an

d

et

c.

An

d

co

m

bu

st

ib

le

ga

s

ca

n

ca

us

e

fir

e.

•

Do

n

ot

in

st

al

l n

or

u

se

th

e

sy

st

em

cl

os

e

to

th

e

eq

ui

pm

en

t t

ha

t g

en

er

at

es

el

ec

tro

m

ag

ne

tic

fi

el

ds

o

rh

ig

h

fre

qu

en

cy

h

ar

m

on

ic

s.

Eq

ui

pm

en

ts

uc

h

as

in

ve

rte

rs

,s

tan

db

yg

en

er

ato

rs

,m

ed

ica

lh

ig

h

fre

qu

en

cy

eq

ui

pm

en

ts

an

d

tel

ec

om

m

un

ica

tio

n

eq

ui

pm

en

ts

ca

n

aff

ec

t t

he

sy

ste

m

, a

nd

ca

us

e

m

alf

un

cti

on

sa

nd

br

ea

kd

ow

ns

.T

he

sy

ste

m

ca

n

als

o

aff

ec

tm

ed

ica

le

qu

ip

m

en

ta

nd

tel

ec

om

m

un

ica

tio

n

eq

ui

pm

en

t,

an

d

ob

str

uc

ti

ts

fu

nc

tio

n

or

ca

us

ej

am

m

in

g.

•

Do

n

ot

in

st

al

l t

he

o

ut

do

or

u

ni

ti

n

a

lo

ca

tio

n

w

he

re

in

se

ct

s

an

d

sm

al

l

an

im

al

s

ca

n

in

ha

bi

t.

In

se

cts

an

d

sm

all

an

im

als

ca

n

en

ter

th

e e

lec

tri

c p

ar

ts

an

d

ca

us

e d

am

ag

e o

r f

ire

.

In

str

uc

t t

he

u

se

r t

o

ke

ep

th

e s

ur

ro

un

di

ng

s c

lea

n.

•

Do

n

ot

us

e

th

e

ba

se

fl

am

e

fo

ro

ut

do

or

un

it

w

hi

ch

is

c

or

ro

de

d

or

d

am

ag

ed

du

e

to

lo

ng

pe

rio

ds

o

f o

pe

ra

tio

n.

Us

in

g

an

ol

d

an

d

da

m

ag

eb

as

ef

lam

ec

an

ca

us

et

he

un

it

fal

lin

g

do

wn

an

d

ca

us

e

pe

rs

on

al

in

ju

ry

.

•

Do

n

ot

u

se

a

ny

m

at

er

ia

ls

o

th

er

th

an

a

fu

se

w

ith

the

c

or

re

ct

ra

tin

g

in

th

e

lo

ca

tio

n

w

he

re

fu

se

s

ar

e

to

b

e

us

ed

.

Co

nn

ec

tin

g

th

e

ci

rc

ui

tw

ith

co

pp

er

w

ire

or

o

th

er

m

et

al

th

re

ad

ca

n

ca

us

e

un

it

fa

ilu

re

a

nd

fi

re

.

•

Do

n

ot

to

uc

h

an

y

bu

tto

ns

w

ith

w

et

ha

nd

s.

It

ca

n

ca

us

e e

lec

tri

c s

ho

ck

s.

•

Do

n

ot

to

uc

h

an

y

re

fri

ge

ra

nt

p

ip

es

w

ith

y

ou

r h

an

ds

w

he

n

th

e

sy

st

em

is

in

op

er

at

io

n.

Du

rin

g

op

er

ati

on

th

er

efr

ig

er

an

tp

ip

es

be

co

m

ee

xtr

em

ely

ho

to

re

xtr

em

ely

co

ld

de

pe

nd

in

g

th

eo

pe

ra

tin

g

co

nd

iti

on

,a

nd

it

ca

n

ca

us

eb

ur

n

in

ju

ry

or

fro

st

in

ju

ry

.

•

Do

n

ot

to

uc

h

th

e

su

ct

io

n

or

a

lu

m

in

um

fin

o

n

th

e

ou

td

oo

r u

ni

t.

Th

is

m

ay

ca

us

ei

nj

ur

y.

•

Do

n

ot

p

ut

a

ny

th

in

g

on

th

e

ou

td

oo

r u

ni

t a

nd

op

er

at

in

g

un

it.

Th

is

m

ay

ca

us

ed

am

ag

et

he

ob

jec

ts

or

in

ju

ry

du

et

o

fal

lin

g

to

th

eo

bj

ec

t.

•

Do

n

ot

u

se

th

e

un

it

fo

r s

pe

ci

al

p

ur

po

se

s

su

ch

as

s

to

rin

g

fo

od

s,

c

oo

lin

g

pr

ec

is

io

n

in

st

ru

m

en

ts

a

nd

p

re

se

rv

at

io

n

of

a

ni

m

al

s,

p

la

nt

s

or

ar

t.

•

Do

n

ot

c

le

an

u

p

th

e

un

it

w

ith

w

at

er

.

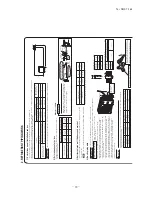

Notabilia as a unit designed for R410A

•

Do

not

use

any

refrigerant

other

than

R410A.

R410A

will

rise

to

pressure

about

1.6

times

higher

than

that

of

a

conventional

refrigerant.

A

cylinder

containing

R410A

has

a

pink

indication

mark

on

the

top.

•

A

unit

designed

for

R410A

has

adopted

a

different

size

indoor

unit

service

valve

charge

port

and

a

different

size

check

joi

nt

provided

in

the

unit

to

prevent

the

charging

of

a

wrong

refrigerant

by

mistake.

The

processed

dimension

of

the

flared

part

of

a

refrigerant

pipe

and

a

flare

nut’s

parallel

side

measurement

have

also

been

al

tered

to

raise

strength

against

pressure.

Accordingly,

you

are

required

to

arrange

dedicated

R410A

tools

listed

in

the

table

on

the

left

before

installing

or

servicing

this

unit.

•

Do

not

use

a

charge

cylinder.

The

use

of

a

charge

cylinder

will

cause

the

refrigerant

composition

to

change,

which

results

in

performance

degradation.

•

In

charging

refrigerant,

always

take

it

out

from

a

cylinder

in

the

liquid

phase.

•

All

indoor

units

must

be

models

designed

exclusively

for

R410A.

Check

connectable

indoor

unit

models

in

a

catalog,

etc.

(A

wr

ong

indoor

unit,

if

connected

into

the

system,

will

impair

proper

system

operation)

Summary of Contents for SRF25ZMXA-S

Page 2: ......

Page 3: ... 14 SRF T 163 TECHNICAL MANUAL ...

Page 12: ... 10 14 SRF T 163 3 Remote control Unit mm 60 26 167 a Wireless remote control ...

Page 93: ... 91 14 SRF T 163 WARING CAUTION 3 Super link E board SC ADNA E F ...

Page 94: ... 92 14 SRF T 163 ...

Page 100: ... 98 14 SRF T 163 CRCE0010 12 13 14 3 2 1 4 4 5 10 10 4 7 8 9 6 15 16 11 CONTROL PARTS SET ...

Page 106: ... 104 14 SRF T 163 CRCE0010 12 13 14 3 2 1 4 4 5 10 10 4 7 8 9 6 15 16 11 CONTROL PARTS SET ...

Page 112: ... 110 14 SRF T 163 CRCE0010 12 13 14 3 2 1 4 4 5 10 10 4 7 8 9 6 15 16 11 CONTROL PARTS SET ...

Page 114: ... 112 14 SRF T 163 CRBE0276 6 13 11 12 15 16 3 17 14 2 4 9 8 7 5 1 8 8 10 PANEL FAN ASSY ...

Page 118: ... 116 14 SRF T 163 CRBE0276 6 13 11 12 15 16 3 17 14 2 4 9 8 7 5 1 8 8 10 PANEL FAN ASSY ...

Page 122: ... 120 14 SRF T 163 CRBE0315 9 13 15 16 14 17 7 6 4 1 8 3 11 5 18 10 10 10 2 12 PANEL FAN ASSY ...