-

106

-

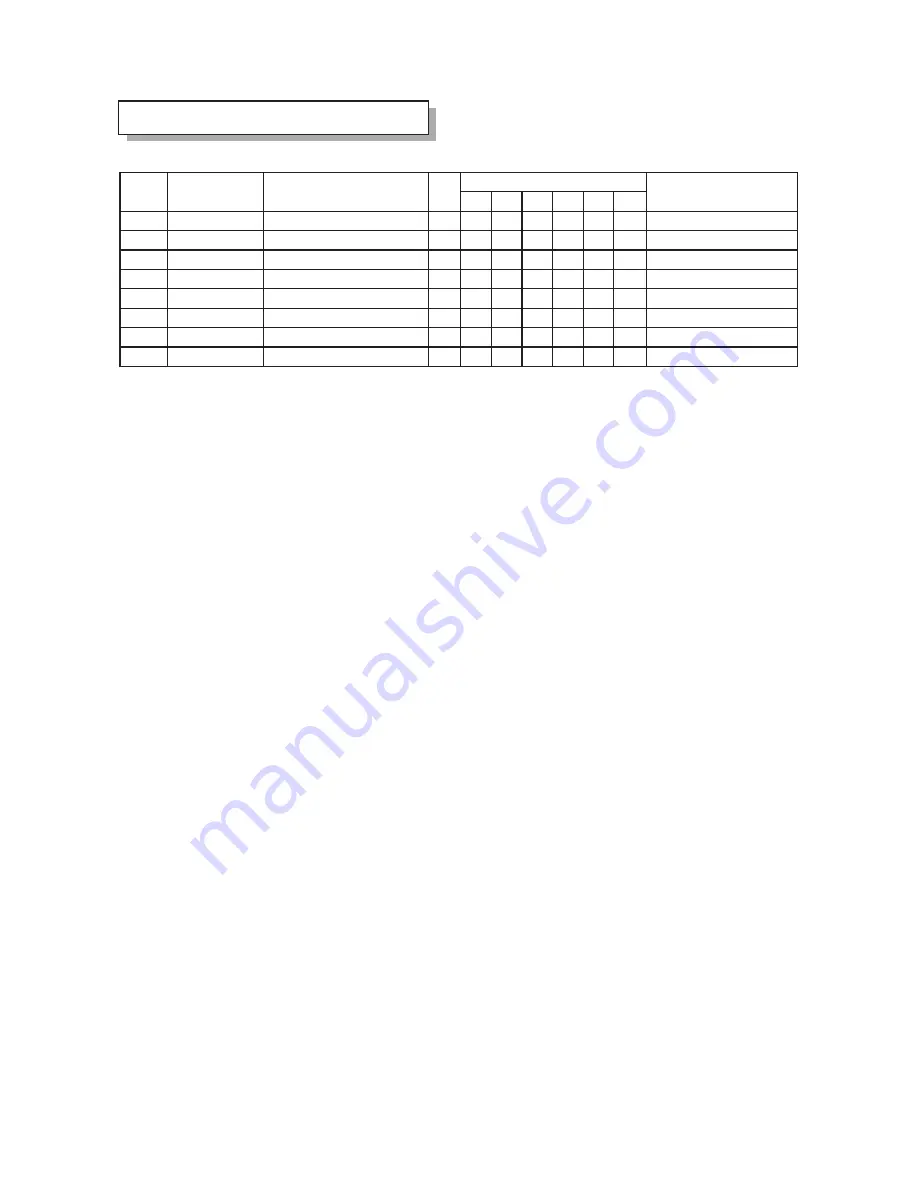

'12•SRK-T-137

SRK19CMS

END ITEM NO. : RMA002F018AD

10

30

50 100 500 1000

39 PHA129A302A COVER ASSY (PIPE)

1

1

1

1

2

4

2

1

1

1

)

R

(

D

I

L

0

0

4

A

2

3

1

W

K

R

0

4

4

2

1

1

1

)

L

(

D

I

L

1

0

4

A

2

3

1

W

K

R

1

4

42-43 RKW132A403

LID ASSY (TERMINAL)

1

1

1

2

4

43 RSA011H027

LABEL, NOTICE

1

44 RKW129A405

COVER PIPE

1

1

1

1

2

45 RKW129A213

HOLDER, FILTER

2

1

1

1

2

46 SSA913A007A SCREW,TAP

4

1

x

4

3

Recommendable Purchased Q'ty

No.

Part No.

Part Name

RE.Q

Note

Summary of Contents for SRK-13CMS-2

Page 46: ... 45 12 SRK T 137 3 Wireless remote control Unit mm 60 17 3 150 Unit mm 60 17 3 150 ...

Page 71: ... 70 12 SRK T 137 4 Troubleshooting procedure If the air conditioner runs NO YES 71 ...

Page 79: ... 78 12 SRK T 137 ...

Page 108: ... 107 12 SRK T 137 MEMO ...

Page 114: ... 113 12 SRK T 137 MEMO ...

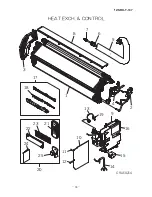

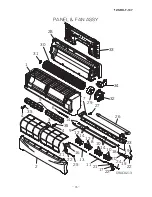

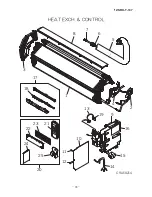

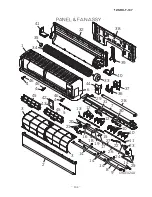

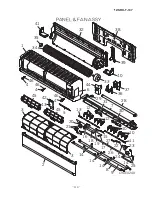

Page 117: ... 116 12 SRK T 137 CRBE0290 6 11 9 10 13 14 3 15 12 2 4 8 7 5 1 7 7 PANEL FAN ASSY ...

Page 121: ... 120 12 SRK T 137 CRBE0290 6 11 9 10 13 14 3 15 12 2 4 8 7 5 1 7 7 PANEL FAN ASSY ...

Page 125: ... 124 12 SRK T 137 CRBE0290 6 11 9 10 13 14 3 15 12 2 4 8 7 5 1 7 7 PANEL FAN ASSY ...

Page 129: ... 128 12 SRK T 137 CRBE0290 6 11 9 10 13 14 3 15 12 2 4 8 7 5 1 7 7 PANEL FAN ASSY ...

Page 133: ... 132 12 SRK T 137 CRBE0290 6 11 9 10 13 14 3 15 12 2 4 8 7 5 1 7 7 PANEL FAN ASSY ...

Page 137: ... 136 12 SRK T 137 CRBE0290 6 11 9 10 13 14 3 15 12 2 4 8 7 5 1 7 7 PANEL FAN ASSY ...

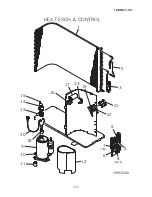

Page 141: ... 140 12 SRK T 137 CRBE0221 12 16 17 1 2 3 5 6 7 8 9 10 13 16 14 15 4 11 PANEL FAN ASSY ...