-

-

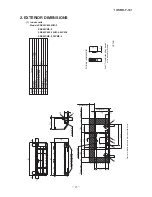

'13•SRK-T-141

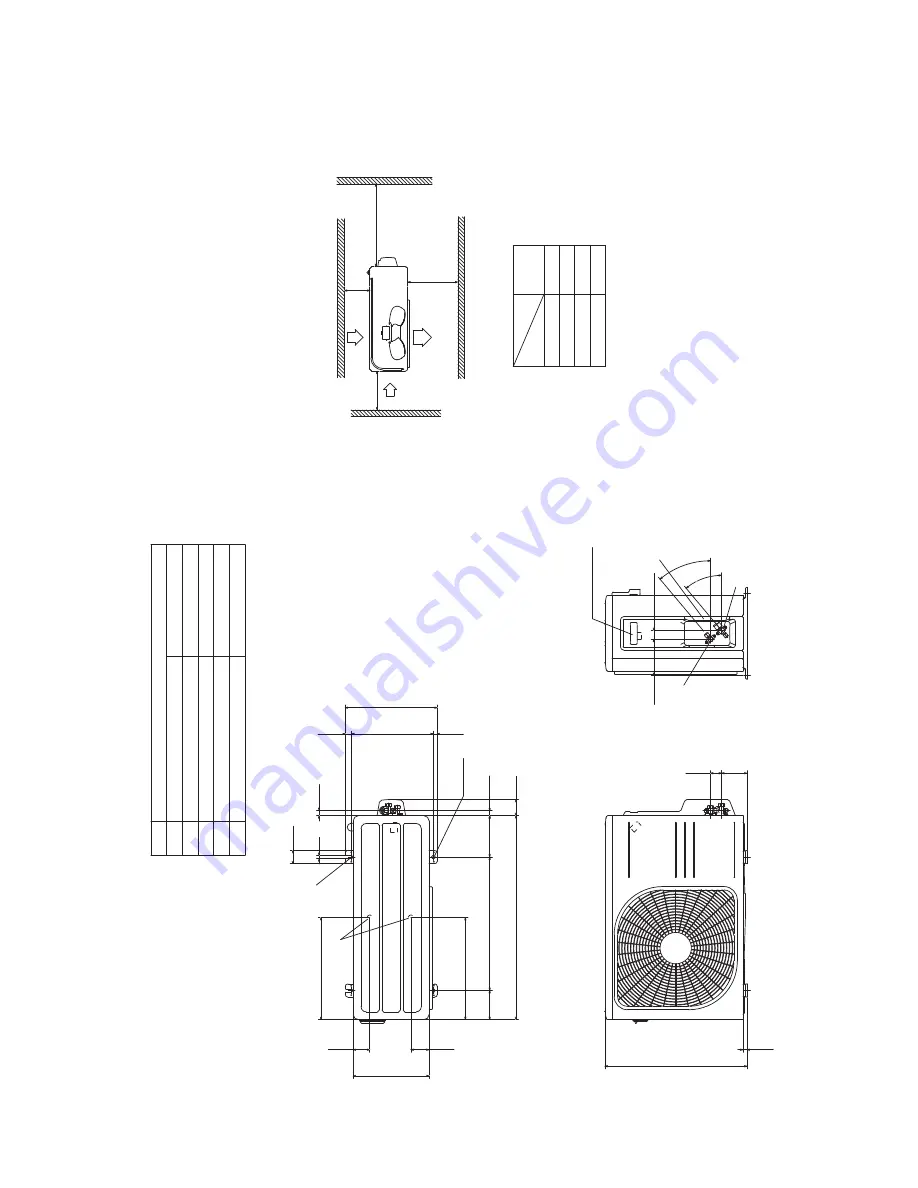

Models SRC12CM-3, 12CM-4, 12CM-5

)

eral

F

()

"4

/

1

(

53.

6

φ

Content

C

Pipe

/

cable draw-out hole

D

E

Anchor bolt hole

Drain discharge hole

Symbol

B

A

Service valve connection

(

gas side

)

M10×4places

φ

20×2places

Service valve connection

(

liquid side

)

)

eral

F

()

"2

/

1

(

7.2

1

φ

L2

Intake

Outlet

Intake

L3

L1

Minimum installation space

Service space

( )

Notes

.se

dis

ruof

lla

no

slla

wy

bd

edn

uorr

us

ebt

ont

su

mtI

)

1

(

(

2

)

The unit must be fixed with anchor bolts.

An anchor bolt must not

protrude more than 15mm.

(

3

)

Where the unit is subject to strong winds, lay it in such

a direction that the blower outlet faces perpendicularly to the dominant wind direction.

(

4

)

Leave 1m or more space above the unit.

(

5

)

A

wall in front of the blower outlet must not exceed the unit he

ight.

(

6

)

The model name label is attached on the right side of the unit.

L4

L2

L3

L4

L1

100

100

600

Open

Examples of

Dimensions

installation

15.8

543.8

390.6

390.6

63.4

69.4

290

11

1.6

510

158.4

780

61.9

18.9

14.8

351.6

2-16x12

312.5

24.3

50.6

12

97.7

42.5

Terminal block

40°

40°

138.4

33.5

19.9

D

E

A

C

B

Unit:mm

mm

Summary of Contents for SRK05CM

Page 2: ... 13 SRK T 141 TECHNICAL MANUAL ...

Page 73: ... 72 13 SRK T 141 CRBE0358 7 4 12 6 1 14 15 7 6 5 8 3 6 9 6 13 11 10 2 PANEL FAN ASSY ...

Page 77: ... 76 13 SRK T 141 CRBE0358 7 4 12 6 1 14 15 7 6 5 8 3 6 9 6 13 11 10 2 PANEL FAN ASSY ...

Page 81: ... 80 13 SRK T 141 CRBE0361 7 4 12 6 1 14 15 7 6 5 8 3 6 9 6 13 11 10 2 PANEL FAN ASSY ...

Page 85: ... 84 13 SRK T 141 CRBE0358 7 4 12 6 1 14 15 7 6 5 8 3 6 9 6 13 11 10 2 PANEL FAN ASSY ...

Page 89: ... 88 13 SRK T 141 CRBE0358 7 4 12 6 1 14 15 7 6 5 8 3 6 9 6 13 11 10 2 PANEL FAN ASSY ...