-

-

'13•SRK-T-141

– 29 –

1 2

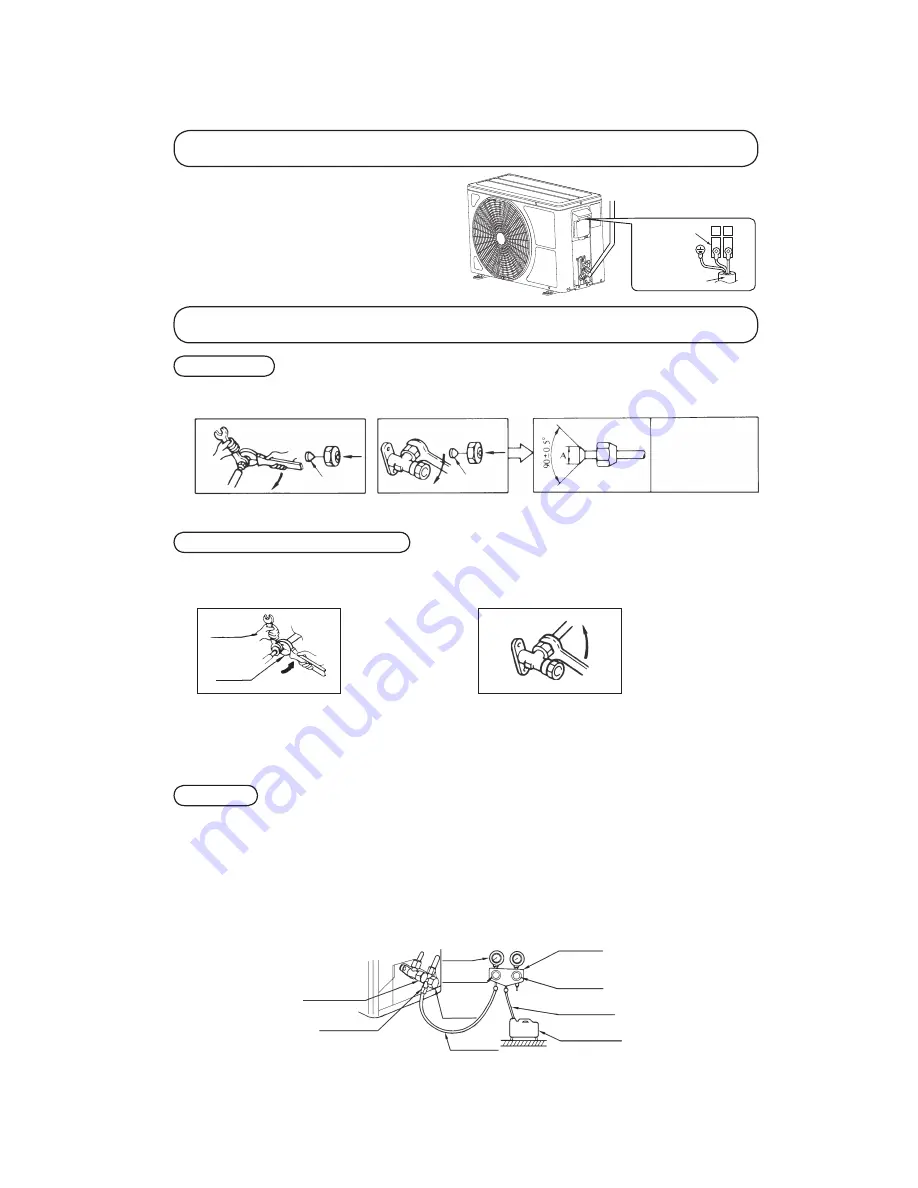

Installation of outdoor unit

1

Make sure that the unit is stable in installation. Fix the unit to

stable base.

2

Perfrom wiring, making wire terminal numbers conform to

terminal numbers of indoor unit terminal block.

3

Earth lead wire shall be longer than the other lead wires for

the electrical safety in case of the slipping out of the cord

from the anchorage.

Terminal block

Interconnecting wire

Connection of refrigerant pipings

Preparation

Connection of refrigerant piping

Air purge

Keep the openings of the pipes covered with tapes etc. to prevent dust, sand, etc. from entering them.

•

Speci

ed torquing value:

Liquid side (ø6.35)

: 14~18N·m (1.4~1.8kgf·m)

Gas side (ø9.52)

: 34~42N·m (3.4~4.2kgf·m)

Gas side (ø12.7)

: 49~61N·m (4.9~6.1kgf·m)

•

Use one more spanner to

x the valve.

1

Tighten all

are nuts in the pipings both indoor and outside wall so as not to cause leak.

2

Connect service valve, charge hose, manifold valve and vacuum pump as is illustrated below.

3

Open manifold valve handle Lo to its full width, and perform vacuum or evacuation.

Continue the vacuum or evacuation operation for 15 minutes or more and check to see that the vacuum gauge reads – 0.1 MPa

(– 76 cmHg).

4

After completing vacuum operation, fully open service valve (Both gas and liquid sides) with hexagon headed wrench.

5

Detach the charge hoses.

6

Check for possible leakage of gas in the connection parts of both indoor and outdoor.

•

Remove the

ared nuts.

(on both liquid and gas sides)

•

Remove the

ared nuts.

(on both liquid and gas sides)

•

Install the removed

ared nuts to the pipes to be connected,

then

are the pipes.

Dimension A

Liquid side

(ø6.35): 9.0 dia

Gas side

(ø9.52): 13.0 dia

(ø12.7): 16.2 dia

Press

Remove

Remove

(Do not

turn)

Spanner

for

the piping)

Torque

wrench

•

Speci

ed torquing value:

Liquid side (ø6.35)

: 14~18N·m (1.4~1.8kgf·m)

Gas side (ø9.52)

: 34~42N·m (3.4~4.2kgf·m)

Gas side (ø12.7)

: 49~61N·m (4.9~6.1kgf·m)

1

Indoor unit side

2

Outdoor unit side

1

Indoor unit side

2

Outdoor unit side

•

Connect

rmly gas and liquid side

pipings by Torque wrench.

•

Connect

rmly gas and liquid side

pipings by Torque wrench.

•

Always use a Torque wrench and back up spanner to tighten the

are nut.

Manifold

Valve

-76 cm Hg

Handle Lo

(pressure)

Charge hose

Stop valve

(Two-way valve)

Service port

Stop value

(Three-way

value)

Compound

(Gauge)

Pressure

gauge

Handle Hi

(pressure)

Charge hose

Vacuum pump

RMA012A065A-067A_Install_EN.indd 29

1/25/2013 1:12:43 PM

Summary of Contents for SRK05CM

Page 2: ... 13 SRK T 141 TECHNICAL MANUAL ...

Page 73: ... 72 13 SRK T 141 CRBE0358 7 4 12 6 1 14 15 7 6 5 8 3 6 9 6 13 11 10 2 PANEL FAN ASSY ...

Page 77: ... 76 13 SRK T 141 CRBE0358 7 4 12 6 1 14 15 7 6 5 8 3 6 9 6 13 11 10 2 PANEL FAN ASSY ...

Page 81: ... 80 13 SRK T 141 CRBE0361 7 4 12 6 1 14 15 7 6 5 8 3 6 9 6 13 11 10 2 PANEL FAN ASSY ...

Page 85: ... 84 13 SRK T 141 CRBE0358 7 4 12 6 1 14 15 7 6 5 8 3 6 9 6 13 11 10 2 PANEL FAN ASSY ...

Page 89: ... 88 13 SRK T 141 CRBE0358 7 4 12 6 1 14 15 7 6 5 8 3 6 9 6 13 11 10 2 PANEL FAN ASSY ...