-

-

'14•SRK-T-153

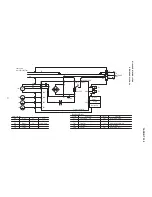

(2) Outdoor units

All models

Symbol

Meaning of Marks

Parts name

Capacitor for CM

Cc

Capacitor for FMo

CFo

Compressor motor

CM

Fan motor

FMo

Motor protector for CM

51C

Terminal block

T

Connector

Sh

1

Power source

220-240V 50Hz

INDOOR

UNIT

FMo

BLACK

ORANGE

W

HI

TE

R

ED

W

HI

TE

Cc

O

R

AN

G

E

CFo

W

H

IT

E

ORANGE

WHITE

WHITE

BLACK

BLACK

WHITE

1

2

T

W

H

IT

E

CM

BLACK

BLACK

51C

2

3

1

RED

C

S

R

Sh

1

T

WHITE

1

2

CAPACITOR

Summary of Contents for SRK10CNS

Page 46: ... 45 14 SRK T 153 3 Wireless remote control Unit mm 60 17 3 150 Unit mm 60 17 3 150 ...

Page 71: ... 70 14 SRK T 153 4 Troubleshooting procedure If the air conditioner runs NO YES 71 ...

Page 79: ... 78 14 SRK T 153 ...

Page 83: ... 82 14 SRK T 153 4 6 10641 ...

Page 87: ... 86 14 SRK T 153 4 6 10641 ...

Page 91: ... 90 14 SRK T 153 4 6 10641 ...

Page 95: ... 94 14 SRK T 153 4 6 10641 ...

Page 99: ... 98 14 SRK T 153 4 6 10641 ...

Page 103: ... 102 14 SRK T 153 4 6 10641 ...

Page 108: ... 107 14 SRK T 153 MEMO ...

Page 114: ... 113 14 SRK T 153 MEMO ...

Page 117: ... 116 14 SRK T 153 CRBE0290 6 11 9 10 13 14 3 15 12 2 4 8 7 5 1 7 7 PANEL FAN ASSY ...

Page 121: ... 120 14 SRK T 153 CRBE0290 6 11 9 10 13 14 3 15 12 2 4 8 7 5 1 7 7 PANEL FAN ASSY ...

Page 125: ... 124 14 SRK T 153 CRBE0290 6 11 9 10 13 14 3 15 12 2 4 8 7 5 1 7 7 PANEL FAN ASSY ...

Page 129: ... 128 14 SRK T 153 CRBE0290 6 11 9 10 13 14 3 15 12 2 4 8 7 5 1 7 7 PANEL FAN ASSY ...

Page 133: ... 132 14 SRK T 153 CRBE0290 6 11 9 10 13 14 3 15 12 2 4 8 7 5 1 7 7 PANEL FAN ASSY ...

Page 137: ... 136 14 SRK T 153 CRBE0290 6 11 9 10 13 14 3 15 12 2 4 8 7 5 1 7 7 PANEL FAN ASSY ...

Page 141: ... 140 14 SRK T 153 CRBE0221 12 16 17 1 2 3 5 6 7 8 9 10 13 16 14 15 4 11 PANEL FAN ASSY ...