-

-

'14•SRK-T-153

Insulation of connecting portion

①

Cover the connection portion of the refrigerant piping with the

pipe cover and seal them.

If neglecting to do so, moisture occurs on the piping and water

will drip out.

②

Finishing and fixing

ⓐ

Tie up the piping with wrapping tape, and shape it so that it conforms

to which the pipe is attached.

ⓑ

Fix them with clamps as right figure.

Vinyl tape

To cover the connecting portion with insula-

tion materials, cut upper portion and then seal

it with insulation materials.

Cover the exterior portion with cov-

ering tape and shape the piping so it

will match the contours of the route

that the piping to take. Also fix the

wiring and pipings to the wall with

clamps.

Insulation

Refrigerant piping

Electrical wiring

Covering tape

Drain hose

Tapping screw

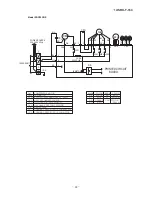

Additional refrigerant charge

Air purge

①

Tighten all flare nuts in the pipings both

indoor and outside wall so as not to

cause leak.

②

Connect service valve, charge hose,

manifold valve and vacuum pump as is

illustrated below.

③

Open manifold valve handle Lo to its

full width, and perform vacuum or

evacuation.

Continue the vacuum or evacuation op-

eration for 15 minutes or more and

check to see that the vacuum gauge

reads – 0.1 MPa (– 76 cmHg).

④

After completing vacuum operation,

fully open service valve (Both gas and

liquid sides) with hexagon headed

wrench.

⑤

Fully open service valve (Both gas and

liguid sides) with hexagon headed

wrench.

⑥

Detach the charge hoses.

⑦

Check for possible leakage of gas in the

connection parts of both indoor and out-

door.

(three-way valve)

Charge hose (Designed specifically for R22)

Compound pressure gauge

Pressure gauge

Gauge manifold

(Designed specifically for R22)

Handle Hi

Vacuum pump

Vacuum pump adapter

(Anti-reverse flow type)

(Designed specifically for R22)

Charge hose

(Designed specifically for R22)

Check joint

-0.1MPa

(-76cmHg)

Handle Lo

Operation valve

Operation valve

(two-way valve)

Operation valve

cap

Operation valve

cap

Operation valve cap

tightening torque (N•m)

Check joint blind nut

tightening torque (N•m)

ø6.35 (1/4")

ø9.52 (3/8")

10~12

ø12.7 (1/2")

25~35

ø15.88 (5/8")

30~40

20~30

Operation valve size

(mm)

Securely tighten the operation valve cap and the check joint blind nut after adjustment.

Please use an anti-reverse flow type vacuum pump adapter so as to prevent vacuum pump oil from running back into the system.

Oil running back into an air-conditioning system may cause the refrigerant cycle to break down.

Additional refrigerant

Less than 7m : Not required

More than 7m :10g/m

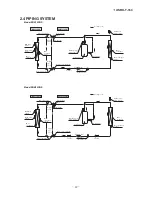

How to relocate or dispose of the unit

In order to protect the environment, be sure to pump down (recovery of

refrigerant).

Pump down is the method of recovering refrigerant from the indoor unit

to the outdoor unit when the pipes are removed from the unit.

<How to pump down>

①

Connect charge hose to check joint.

②

Liquid side : Close the liquid valve with hexagon wrench key.

Gas side : Fully open the gas valve.

Carry out cooling operation. (If indoor temperature is low, operate

forced cooling operation.)

③

After low pressure gauge become 0.01MPa, close the gas valve then

stop cooling operation.

Forced cooling operation

Turn on a power supply again after a while after turn

off a power supply. Then press continually the ON/

OFF button 5 seconds or more.

Unit ON/OFF button

Summary of Contents for SRK10CNS

Page 46: ... 45 14 SRK T 153 3 Wireless remote control Unit mm 60 17 3 150 Unit mm 60 17 3 150 ...

Page 71: ... 70 14 SRK T 153 4 Troubleshooting procedure If the air conditioner runs NO YES 71 ...

Page 79: ... 78 14 SRK T 153 ...

Page 83: ... 82 14 SRK T 153 4 6 10641 ...

Page 87: ... 86 14 SRK T 153 4 6 10641 ...

Page 91: ... 90 14 SRK T 153 4 6 10641 ...

Page 95: ... 94 14 SRK T 153 4 6 10641 ...

Page 99: ... 98 14 SRK T 153 4 6 10641 ...

Page 103: ... 102 14 SRK T 153 4 6 10641 ...

Page 108: ... 107 14 SRK T 153 MEMO ...

Page 114: ... 113 14 SRK T 153 MEMO ...

Page 117: ... 116 14 SRK T 153 CRBE0290 6 11 9 10 13 14 3 15 12 2 4 8 7 5 1 7 7 PANEL FAN ASSY ...

Page 121: ... 120 14 SRK T 153 CRBE0290 6 11 9 10 13 14 3 15 12 2 4 8 7 5 1 7 7 PANEL FAN ASSY ...

Page 125: ... 124 14 SRK T 153 CRBE0290 6 11 9 10 13 14 3 15 12 2 4 8 7 5 1 7 7 PANEL FAN ASSY ...

Page 129: ... 128 14 SRK T 153 CRBE0290 6 11 9 10 13 14 3 15 12 2 4 8 7 5 1 7 7 PANEL FAN ASSY ...

Page 133: ... 132 14 SRK T 153 CRBE0290 6 11 9 10 13 14 3 15 12 2 4 8 7 5 1 7 7 PANEL FAN ASSY ...

Page 137: ... 136 14 SRK T 153 CRBE0290 6 11 9 10 13 14 3 15 12 2 4 8 7 5 1 7 7 PANEL FAN ASSY ...

Page 141: ... 140 14 SRK T 153 CRBE0221 12 16 17 1 2 3 5 6 7 8 9 10 13 16 14 15 4 11 PANEL FAN ASSY ...