-

-

'15 • SRK-T-172

Insulation of connecting portion

①

Cover the connection portion of the refrigerant piping with the pipe

cover and seal them.

If neglecting to do so, moisture occurs on the piping and water will

drip out.

②

Finishing and fixing

ⓐ

Tie up the piping with wrapping tape, and shape it so that it

conforms to which the pipe is attached.

ⓑ

Fix them with clamps as right figure.

Vinyl tape

To cover the connecting portion with

insulation materials, cut upper portion

and then seal it with insulation

materials.

Cover the exterior portion

with covering tape and shape

the piping so it will match the

contours of the route that the

piping to take. Also fix the

wiring and pipings to the wall with

clamps.

Insulation

Refrigerant piping

Electrical wiring

Covering tape

Drain hose

Tapping screw

g

Additional refrigerant charge

Models SRK10CRV-S

SRK13CRV-S

SRK10CRS-S, S3, S4, S5, S6

SRK13CRS-S, S3, S4, S5, S6

Models SRK10CRV-S1

SRK13CRV-S1

SRK10CRS-S1, S2

SRK13CRS-S1, S2

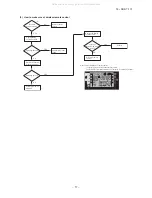

Air purge

Securely tighten the operation valve cap and the check joint blind nut

after adjustment.

Operation valve size

(mm)

Operation valve cap

tightening torque (N·m)

Check joint blind nut

tightening torque (N·m)

F

6.35 (1/4")

20 ~ 30

10 ~ 12

F

9.52 (3/8")

F

12.7 (1/2")

25 ~ 35

F

15.88 (5/8")

30 ~ 40

Compound pressure gauge

Operation valve cap

Operation valve

(three-way valve)

Operation valve

cap

-0.1MPa

(-76cmHg)

Handle Lo

Pressure gauge

Handle Hi

Charge hose

(Designed specifically for R410A)

Vacuum pump adapter

(Anti-reverse flow type)

(Designed specifically for R410A)

Vacuum pump

Charge hose (Designed specifically for R410A)

Check joint

Operation valve

(two-way valve)

Gauge manifold

(Designed specifically

for R410A)

①

Tighten all flare nuts in the pipings both indoor

and outside wall so as not to cause leak.

②

Connect operation valve, charge hose, manifold

valve and vacuum pump as is illustrated right.

③

Open manifold valve handle Lo to its full

width, and perform vacuum or evacuation.

Continue the vacuum or evacuation operation

for 15 minutes or more and check to see that

the vacuum gauge reads -0.1MPa.

④

After completing vacuum operation, close the

Lo handle and stop operation of the vacuum

pump.

⑤

After completing vacuum operation, fully

open operation valve (Both gas and liquid

sides) with hexagon headed wrench.

⑥

Check for possible leakage of gas in the

connection parts of both indoor and outdoor.

v

Since the system uses check joints differing in diameter

from those found on the conventional models, a charge hose

(for R22) presently in use is not applicable. Please use one

designed specifically for R410A.

v

Please use an anti-reverse flow type vacuum pump adapter

so as to prevent vacuum pump oil from running back into

the system. Oil running back into an air-conditioning system

may cause the refrigerant cycle to break down.

When refrigerant piping exceeds 5m conduct additional refrigerant charge after refrigerant sweeping.

5m over 15m: Additional charge amount per meter = 10g/m

[Example]

How much amount of additional charge for 15m piping?

(15 - 5)m × 10g/m = 100g

100g for additional charge

g

Additional refrigerant charge

When refrigerant piping exceeds 7.5m conduct additional refrigerant charge after refrigerant sweeping.

7.5m over 15m: Additional charge amount per meter = 10g/m

[Example]

How much amount of additional charge for 15m piping?

(15 - 7.5)m × 10g/m = 75g

75g for additional charge

All manuals and user guides at all-guides.com

Summary of Contents for SRK10CRS-S

Page 2: ...All manuals and user guides at all guides com ...

Page 3: ... 15 SRK T 172 TECHNICAL MANUAL All manuals and user guides at all guides com ...

Page 60: ... 58 All manuals and user guides at all guides com ...

Page 64: ... 62 15 SRK T 172 4 6 10641 All manuals and user guides at all guides com ...

Page 68: ... 66 15 SRK T 172 4 6 10641 All manuals and user guides at all guides com ...

Page 72: ... 70 15 SRK T 172 4 6 10641 All manuals and user guides at all guides com ...