-

124

-

(2)

Servicing

(a)

Evacuation

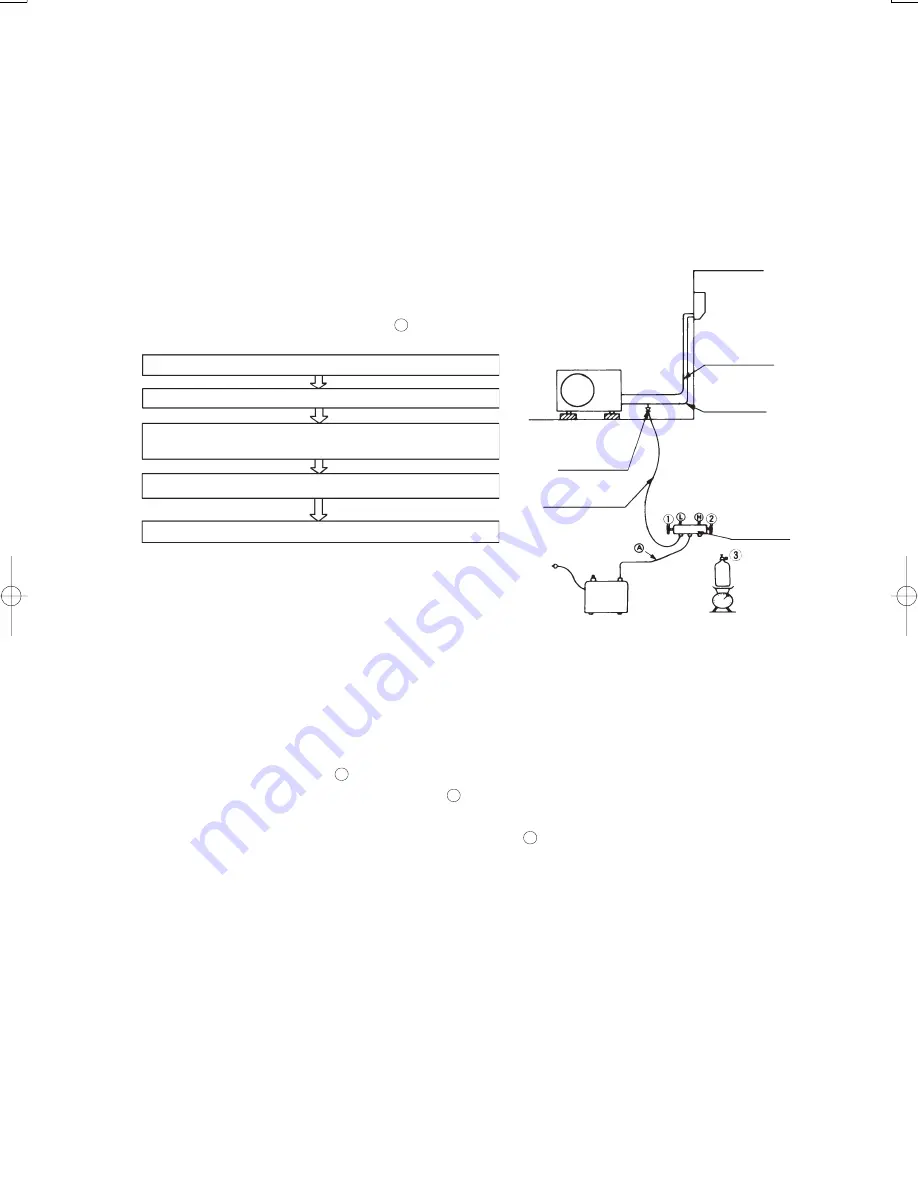

The evacuation is an procedure to purge impurities......noncondensable gas, air, moisture from the refrigerant equipment by using

a vacuum pump. Since the refrigerant R410A is very insoluble in water, even a small amount of moisture left in the refrigerant

equipment will freeze, causing what is called water clogging.

¡

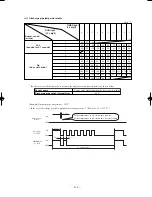

Evacuation procedure

(i)

Check to ensure that there is no internal pressure in the unit. If there is an internal pressure, it

should be relieved through the check joint.

(ii)

Connect the service hoses of the gauge manifold to the check joint of the gas & liquid piping.

(iii) Connect a vacuum pump to the charge hose A . Repeat evacuation in the following sequence.

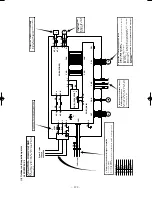

(b)

Refrigerant charge

(i)

Discharge refrigerant entirely from the unit and evacuate the unit.

Note: Addition of refrigerant without evacuation is unreasonable, because it will result in low charge or overcharge.

(ii)

Keep the gauge manifold and connect a refrigerant cylinder to the unit.

(iii) Record the weight of the refrigerant cylinder on the balance. This is necessary for making sure of the charged refrigerant

amount.

(iv) Purge air from the charge hose A

Firstly loose the connecting portion of the charge hose A at the gauge manihold side and open the valve

3

for a few seconds,

and then immediately retighten it after observing that gas is blow out from the loosened portion.

(v)

Open the valve

1

and

3

after discharging air from the charge hose A , then the liquid refrigerant begins flowing from the

cylinder into the unit. Be sure to erect the refrigerant cylinder upright to let liquid refrigerant flow into the unit.

(vi) When refrigerant has been charged into the system to some extent, refrigerant flow becomes stagnant, when that happens,

start the compressor in cooling cycle until the unit is filled with refrigerant to the specified weight.

(vii) Making sure of the refrigerant amount, close the valve

3

(viii) Disconnect the charge hose from the unit. Cover the valve ports of the refrigerant piping with caps and tighten them securely.

(ix) Check for gas leakage applying a gas leak detector along the piping line.

(x)

Start the air conditioner and make sure of its operating condition......high side and low side pressures and temperature difference

between return air and supply air.

2.7 REFRIGERANT PIPING INSTALLATION/SERVICING

MANUAL FOR AIR CONDITONERS USING R410A

This is same as chapter 1.7. Refer to page 45.

Notes (1) Do not use the refrigerant pressure to expel air.

(2) Do not use the compressor for evacuation.

(3) Do not operate the compressor in the vacuum condition.

Service hose

Liquid side

Gas side

Check joint

Charge hose

Vacuum

pump

Refrigerant

cylinder

Gauge

manifold

Stop the vacuum pump.

Start the vacuum pump.

Compound pressure gauge indicates –0.1 MPa (–76 cmHg)

Operate the vacuum pump for more than 15 minutes after –0.1 MPa

(–76 cmHg) is indicated.

Close low pressure valve

1

of gauge manifold.

Summary of Contents for SRK13ZEV-S4

Page 2: ...TECHNICAL MANUAL 1 SRK13ZEV S4 2 2 SRK22ZEV S4 60 1 ...

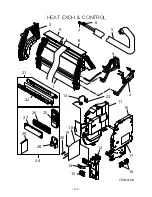

Page 126: ...PARTS LIST INDOOR UNIT SRK13ZEV S4 SRK22ZEV S4 OUTDOOR UNIT SRC13ZEV S4 SRC22ZEV S4 125 ...

Page 134: ...MEMO 133 ...

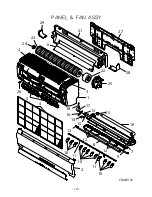

Page 137: ... 136 CRBE0226 1 3 4 2 5 6 7 8 9 10 11 12 13 PANEL FAN ASSY ...

Page 145: ...ROOM AIR CONDITIONING TECHNICAL MANUAL PARTS LIST Manual No 06 SRK T 054 ...