-

14

-

Timer operation

(time)

Temperature

setting (˚C)

Start

Heating

0

-1.0

-2.0

-3.0

-6.0

0

0.5

1.0

2.0

Start

Timer operation

(time)

Temperature

setting (˚C)

Cooling

+1.0

0

-1.0

0

1.0

2.0

(2)

Sleep timer operation

Pressing the SLEEP button causes the temperature to be controlled as shown in the following chart with respect to the set

temperature.

4.6 Timer operation

(1)

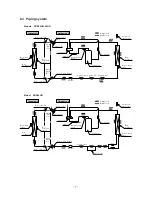

Comfortable timer setting (ON timer)

(3)

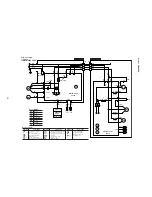

OFF timer operation

The Off timer can be set at a specific time (in 10-minute units) within a 24-hour period.

Corrects the starting time of next operation by

calculating the temperature difference.

(Example) Heating

Setting temperature

Room temperature

Operation starting time

Time

Setting time

15 min.

10 min.

5 min.

earlier

earlier

earlier

¡

If the difference (= Setting temperature – Room tempera-

ture) is 4ºC, the correction value is found to be +5 min-

utes from the table shown above so that the starting time

of next operation is determined as follows:

15 min. e 5 min. = 20 min. earlier

↑

↑

Current operation

Correction value

start time

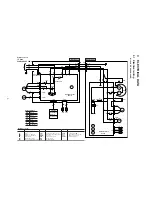

If the timer is set at ON when the operation select switch is set at the cooling or heating, or the cooling or heating in auto mode

operation is selected, the comfortable timer starts and determines the starting time of next operation based on the initial value of 15

minutes and the relationship between the room temperature at the setting time (temperature of room temperature sensor) and the

setting temperature. (Max. 60 minutes)

Operation mode

Operation start time correction value (Min.)

3 < Room temp. – Setting temp.

1 < Room temp. – Setting temp. 3

Room temp. – Setting temp. 1

At cooling

+5

No change

–5

3 < Setting temp. – Room temp.

2 < Setting temp. – Room temp. 3

Setting temp. – Room temp. 2

At heating

+5

No change

–5

Notes (1) At 5 minutes before the timer ON time, operation starts regardless of the temperature of the room temperature sensor (Th1).

(2) This function does not operate when in the Dry or Auto Dry mode.

However, the operation in item (1) does operate in the Auto Dry mode.

(3) During the comfortable timer operation, both the RUN light and TIMER light illuminate and the TIMER light goes off after expiration of the timer, ON setting

time.

=

<

=

<

=

<

=

<