-

33

-

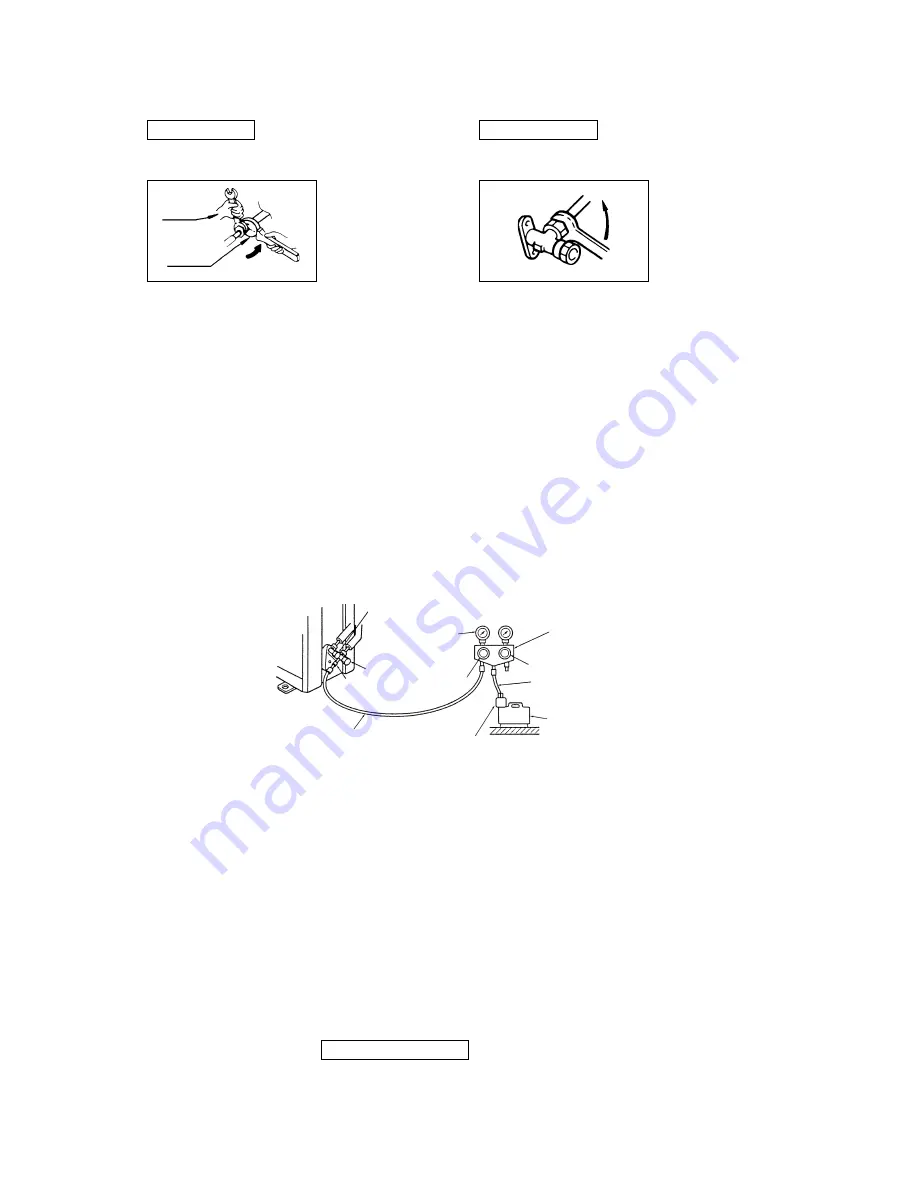

Service Valve

(three-way valve)

Charge hose

(Designed specifically for R410A)

Compound

pressure

gauge

Pressure

gauge

Gauge Manifold

(Designed specifically for R410A)

Handle Hi.

Vacuum pump

Vacuum pump adapter

(Anti-reverse flow type)

(Designed specifically for R410A)

Charge hose

(Designed specifically for R410A)

Service Port

—0.1MPa

(—76cmHg)

Handle Lo

Service Valve

(two-way valve)

¡

Always use a Torque wrench and back up spanner to tighten the flare nut.

(c)

Air purge

(i)

Tighten all flare nuts in the pipings both indoor and outside will so as not to cause leak.

(ii)

Connect service valve, charge hose, manifold valve and vacuum pump as is illustrated below.

(iii) Open manifold valve handle Lo to its full width, and perform vacuum or evacuation.

Continue the vacuum or evacuation operation for 15 minutes or more and check to see that the vacuum gauge reads – 0.1

MPa (– 76 cmHg).

(iv) After completing vacuum operation, fully open service valve (Both gas and liquid sides) with hexagon headed wrench.

(v)

Detach the charge hoses.

(vi) Check for possible leakage of gas in the connection parts of both indoor and outdoor.

(b)

Connection of refrigerant piping

Indoor unit side

¡

Connect firmly gas and liquid side

pipings by Torque wrench.

Outdoor unit side

¡

Connect firmly gas and liquid side

pipings by Torque wrench.

¡

Specified torquing value:

Liquid side (ø6.35) : 14.0~18.0N·m (1.4~1.8kgf·m)

Gas side (ø9.52)

: 34.0~42.0N·m (3.4~4.2kgf·m)

(ø12.7)

: 49.0~61.0N·m (4.9~6.1kgf·m)

¡

Use one more spanner to fix the valve.

Spanner

(for fixing

the piping)

Torque

wrench

¡

Specified torquing value:

Liquid side (ø6.35) : 14.0~18.0N·m (1.4~1.8kgf·m)

Gas side (ø9.52)

: 34.0~42.0N·m (3.4~4.2kgf·m)

(ø12.7)

: 49.0~61.0N·m (4.9~6.1kgf·m)

¡

Since the system uses service ports differing in diameter from those found on the conventional models, a charge hose (for R22)

presently in use is not applicable.

Please use one designed specifically for R410A

¡

Please use an anti-reverse flow type vacuum pump adapter so as to prevent vacuum pump oil from running back into the system.

Oil running back into an air-conditioning system may cause the refrigerant cycle to break down.

Additional refrigerant charge

¡

20, 25, 35 type

Additional refrigerant charge is not required at all.

¡

50 type

When refrigerant piping exceeds 15m conduct additional refrigerant charge by weight after refrigerant piping completion.

Additional charge amount per meter = 20g/m

[Example]

How much amount of additional charge for 25m piping?

(25 – 15)m

×

20g/m = 200g

200g for additional charge

Summary of Contents for SRK56CE-S1

Page 138: ... 136 MEMO ...

Page 262: ... 260 MEMO ...