-

76

-

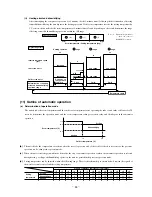

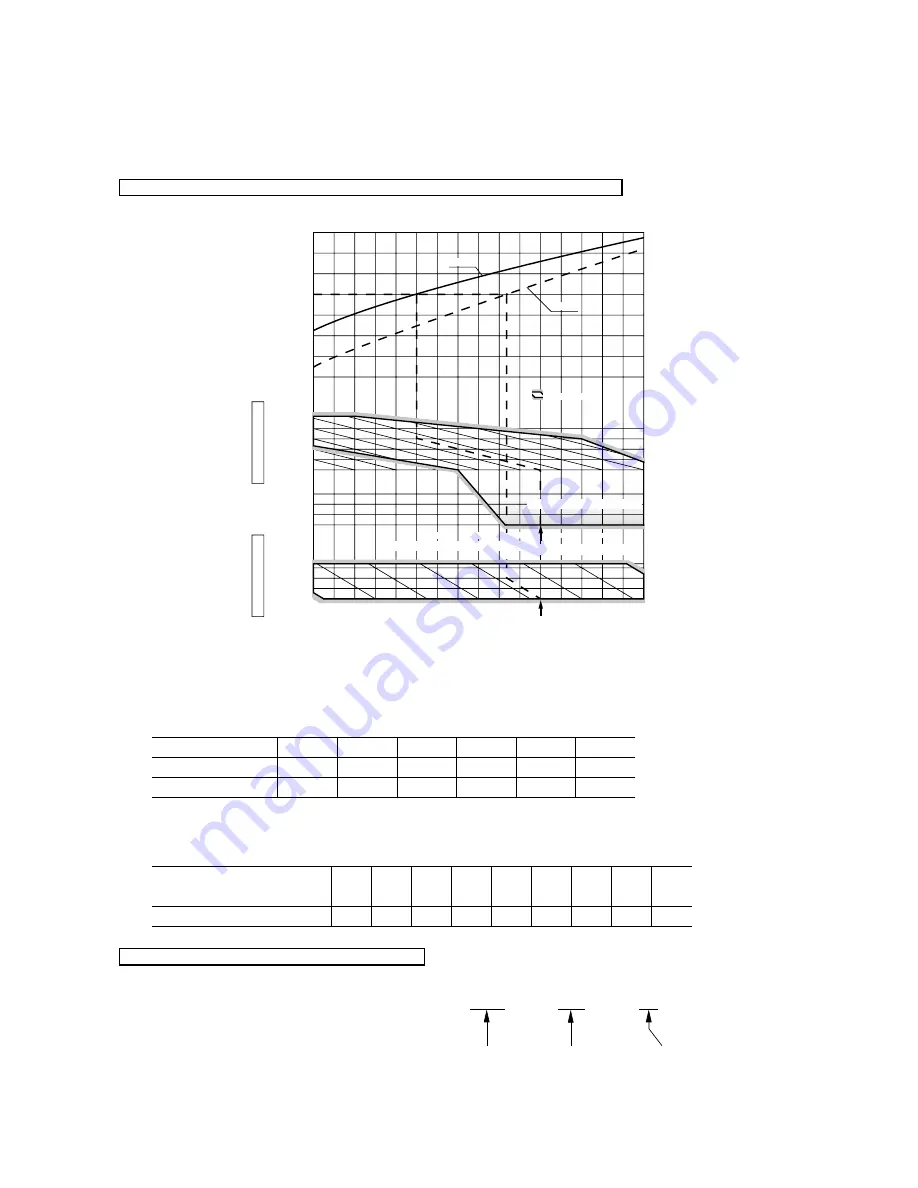

(5) Selection chart

Correct the cooling and heating capacity in accordance with the conditions as follows. The net cooling and heating capacity can be

obtained in the following way.

Net capacity = Capacity shown on specification

✕

Correction factors as follows.

(a)

Coefficient of cooling and heating capacity in relation to temperatures

(b)

Correction of cooling and heating capacity in relation to one way length of refrigerant piping

It is necessary to correct the cooling and heating capacity in relation to the one way piping length between the indoor and outdoor

units.

(c)

Correction relative to frosting on outdoor heat exchanger during heating

In additions to the foregoing corrections (a), (b) the heating capacity needs to be adjusted also with respect to the frosting on the

outdoor heat exchanger.

How to obtain the cooling and heating capacity

Example : The net cooling capacity of the model SRK63ZE-S1 with the piping length of 15m, indoor wet-bulb temperature at 19.0˚C

and outdoor dry-bulb temperature 35˚C is Net cooling capacity = 6300

✕

0.975

✕

1.0

=

6143W

SRK63ZE-S1

Length 15m

Factor by air

temperatures

Cooling

Heating

22

20

18

16

14

0.6

0.7

0.8

0.9

1.0

1.2

1.1

1.3

0

-5

-10

-15

Applicable range

Depends on installed situation

24

26

20

25

30

35

40

46

10

15

20

25

27

Outdoor air W.B. temperature ˚C W.B.

-15

-10

-5

0

5

10

15

Indoor air W.B. temperature ˚C W.B. ISO-T1 Standard Condition

Cooling operation

Outdoor air D.B.

temperature

˚CD. B.

Coefficient of cooling

&

Heating capacity in

relation to temperature

Heating operation

Indoor air D.B.

temperature

˚CD. B.

ISO-T1 Standard Condition

Piping length [m]

Cooling

Heating

7

1.0

1.0

10

0.99

1.0

15

0.975

1.0

20

0.965

1.0

25

0.95

1.0

0.935

1.0

30

Air inlet temperature of

outdoor unit in ˚C WB

Adjustment coefficient

-10

0.95

-9

0.94

-7

0.93

-5

0.91

-3

0.88

-1

0.86

1

0.87

3

0.92

5

1.00

Summary of Contents for SRK56CE-S1

Page 138: ... 136 MEMO ...

Page 262: ... 260 MEMO ...