-

101

-

'17 • SCM-T-225

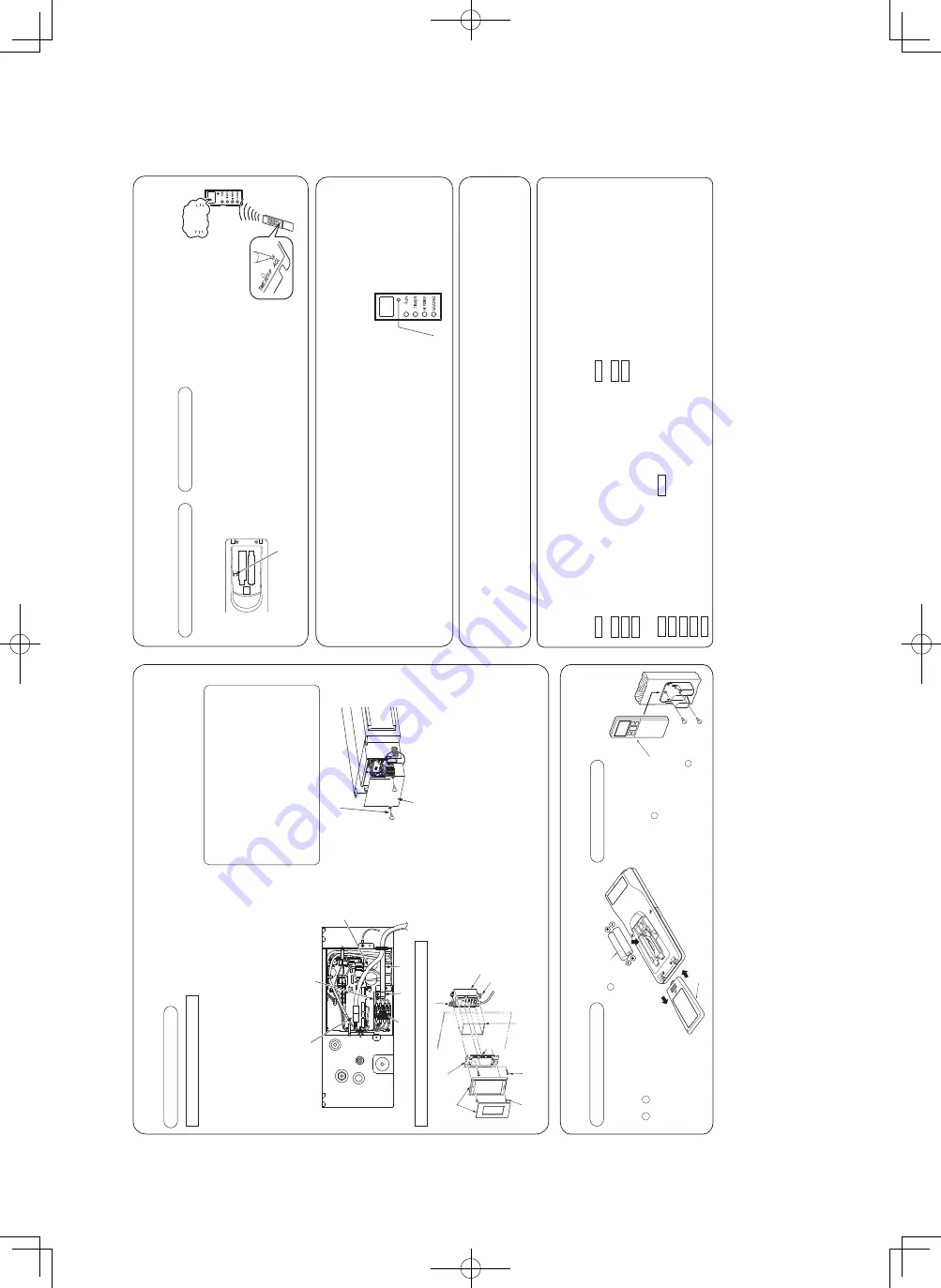

• Flaring work

Measurement B

Flaring block

Copper pipe

○ Install the removed flared nuts to the pipes to be connected,

then flared the pipes.

○ Remove the flared nuts. (on both liquid and gas sides)

Keep the openings of the pipes covered with tapes etc. to preve

nt dust, sand, etc. from entering them.

CONNECTION OF REFRIGERANT PIPINGS

INSTALLATION OF INDOOR UNIT

Preparation

(Do not turn)

Press

Remove

A

90 ± 0.5˚

Dimension A Liquid side ø6.35 :

9.1 (mm)

Gas side ø9.52 : 13.2 (mm)

ø12.7 : 16.6 (mm)

CAUTION

Do not apply refrigerating machine oil to the flared surface.

Indoor

CAUTION

Do not apply excess torque to the flared nuts. Otherwise, the flared nuts may crack.

TERMINAL CONNECTION FOR AN INTERFACE

Remove the control lid. (Remove the screw.) There is a terminal (respectively marked with CNS)

for the indoor control board.

In connecting an interface, connect to the respective terminal

securely with the connection harness supplied with an option

“

Interface connection kit SC-BIKN2-

E

” and

fasten the connection harness onto the indoor control box with

the clamp supplied with the kit.

For more details, please refer to the user’s manual of your

“

Interface connection kit SC-BIKN-

E

”.

○

Connect the pipes on both liquid and gas

s

ides.

○

Tighten the nuts to the following torque.

Liquid side

(ø6.35) : 14.0 - 18.0 N

·

m (1.4 - 1.8 kgf

·

m)

Gas side

(ø9.52) : 34.0 - 42.0 N

·

m (3.4 - 4.2 kgf

·

m)

(ø12.7) : 49.0 - 61.0 N

·

m (4.9 - 6.1 kgf

·

m)

Connection

Indoor

(Do not turn)

Remove the control lid. Remove the wiring clamp. Connect the connecting wire to the terminal block. 1)

Connect the connect

ion wire securely. If the wire is not affixed completely,

contact will be poor, and it is dangerous as the terminal bl

ock may heat up

and catch fire.

2)

Take care not to confuse the terminal numbers for indoor and

outdoor

connections.

Fix the connect

ing wire by wiring clamp.

C

onnect the connecto

r

of the

remote cont

rol singnal

r

eceive

r t

o

the

r

elay

wi

ring

.

Attach the control lid.

ELECTRICAL WIRING WORK

Preparation of indoor unit

Mounting of connecting wires

RJJ012A002

Liquid side Gas side

Use cables for interconnection wiring to avoid loosening of the

wires.

CENELEC code for cables Required field cables.

H05RNR4G1.5 (example) or 245IEC57 H Harmonized cable type 05 300/500 volts R Natural-and/or synth, rubber wire insulation N Polychloroprene rubber conductors insulation R Stranded core 4or5 Number of conductors G One conductor of the cable is the earth conductor (yellow/green) 1.5 Section of copper wire (mm

2

)

○

In case of faulty wiring connect

ion, indoor unit does not operate. Then, run lamp turns on and

timer lamp blinks.

○

Attach the washers and nuts to the suspensi

on bolts.

○

Attach the hanging tool to the above nuts, and tighten the nuts

.

M10 washer

M10 nut

M10 suspension bolt

M10 nut

M10 washer

M10 spring lock washer

Main fram

e

Inserts

Holed anchor Holed plug

Suspension bolts M10

Concrete

If steel embedded ceilin

g

Let

the

pipe

side

be

slightly

sloped.

Pipe side

Pour water

Water

surface

0~5mm

Vinyl hose

B

A

unit : mm

Model

25, 35 50, 60

Inlet

160

Outlet

99

Adjustment for horizontality

•

Adjust so the bottom side of

the unit will be leveled with

the water surface as

illustrated belo

w

.

Air inlet and outlet size

○

Size of air inlet and outlet of the plate.

○ Cover the flare connection part of the indoor unit with attach

ed insulation material after a gas leakage

inspection, and tighten both ends with attached bands.

•

Make sure to insulate both gas pipes and liquid pipes complete

ly.

※

Incomplete insulation may cause dew condensation or water dropp

ing.

•

Use heat-resistant (120 °C or more) insulations on the gas sid

e pipes.

•

In case of using at high humidity condition, reinforce insulat

ion of refrigerant pipes.

Surface of insulation may cause dew condition or water dropping

, if insulations are not reinfoced.

<

The case of using thickness of insulation is 10mm

>

<

The case of using reinfoced insulation

>

Pipe cover

Unit

Unit

Band

Band (Prepare on site)

Insulation (Prepare on site)

Pipe cover (Prepare on site)

Band

The thickness of insulation is 10mm

•

If the bottom drain piping can be done with a descending gradie

nt (1/50-1/100), it is

possible to connect the pipes as shown in the drawing below.

•

When sharing a drain pipe for more than one unit, lay the main

pipe 100mm

below the drain outlet of the unit. In addition, select VP-30 o

r bigger size for

main drain pipe.

Descending slope greater than 1/100

VP-30 or bigger

As wide as possible

(about100mm)

○

Install the drain pipe according to the installation manual in

order to drain properly.

Imperfection in draining may cause flood indoors and wetting t

he househol

d goods, etc.

○

Do not put the drain pipe directly into the ditch where toxic

gas such as sulfur, the other harmful and inflammable gas is

generated. Toxic gas would flow into the room and it

would cause serious damage to user’s health and safety (some

poisoning or deficiency of oxygen). In addition, it may cause

corrosion of heat exchange

r

and bad smell.

○

Connect the pipe securely to avoid water leakage from the joint

.

○

Insulate the pipe properly to avoid condensat

ion drop.

○

Check if the water can flow out properly from both the drain

outlet on the indoor unit and the end of the drain pipe after i

nstallation.

Insulating material (to be removed)

Joint

Rubber stopper (to be removed)

Standard hard polyvinyl chloride pipe

Connecting port of bottom

drain pipes

(Outside diameter:25mm)

Connecting port of top drain pipe

DRAIN PIPE

(3)

Make sure to make descendi

ng slope of greater than 1/100 and do

not make up-down bend and/or trap in the midwa

y.

•

Pay attention not to give stress on the pipe on the indoor unit

side, and support and fix the pipe as close place to the unit

as possible when connecting the drain pipe.

•

Do not set up air vent.

Drain hose

Joint

Drain hose (VP25)

Cramp

(1)

Insert the joint to the drain hose on the indoor unit and fix i

t securely with the clamp (small).

•

Do not apply adhesives on this end.

(2)

Connect the drain pipe (VP25) to the joint and fix it seaurely

with the clamp (big).

•

The position for drain pipe outlet can be raised up to 600mm ab

ove the ceiling. Use elbows

for installation to avoid obstacles inside ceiling. If the hori

zontal drain pipe is too long

before vertical pipe, the backflow of water will increase when

the unit is stopped, and it

may cause overflow of water from the drain pan on the indoor un

it. In order to avoid

overflow, keep the horizontal pipe length and offset of the pip

e within the limit shown in the

figure below.

(4)

Insulate the drain pipe.

•

Be sure to insulate the joint and the drain pipe installed i

ndoor otherwise it may cause dew condensat

ion and water leakage.

Drain up

235~265mm

Drain hose

Maximum local

drain up dimension

Joint for VP25 (Prepare on site)

600

Right overhead

Pour water in the drain pan with a siphon.

Pouring water hose

Drain pan

Remove grommet from the unit.

Gromment

Outline of bottom drain piping work

Securing the suspension bolt

s

Installing the main unit

If wooden ceilin

g

Holes for suspention bolts

Clamps

Beams

Square bars for suspension the air-conditioner

○

Either use a level vial, or adjust the level according to the m

ethod belo

w

.

○

If the unit is not leveled, it may cause malfunctions or inoper

ation of the float switch.

Work procedure

Securing the remote control signal receiver

(1)

Open a through-

hole on the wall to install the reception face for the

remote control signal receiver

③

.

(2)

Insert the remote control signal receiver

③

in the installation frame

4

,

and fix the calking section.

(3)

Fix the installation frame

④

on the wall using the flat head machine

screws

⑩

.

(4)

Fix the plate (display)

⑪

on the installation frame

④

using the flat head

machine screws packed

together with the plate (display)

⑩

.

⑪

Plate (display

)

⑩

Flat head machine scre

w

Flat head machine scre

w

(In the pack of

⑪

)

④

Installation fram

e

③

Remote control signal receiver

Cut o

ff this section if it interferes with the wall

.

Calkin

g

Calkin

g

Cut o

ff this section if it interferes

with the wall

.

○

Conventionally,

operate

the

wireless

remote

control

by

holding

in

your

hand.

○

Avoid

installing

it

on

a

clay

wall

etc.

INSTALLATION OF WIRELESS REMOTE CONTROL

Mounting method of battery

Fixing to pillar or wall

1

Wood screws ø3.5 X 16

Wireless remote control

5

Cover

Battery

6

○

Pull

out

the

cover

and

mount

the

batteries

[R03

(AAA,

Micro),

×

2

pieces]

in

the

body

regularly. (Fit

the

poles

with

the

indication

marks,

+

&

−

without

fail)

○

Do not use new and old batteries together.

Disconnect

When

two

air-conditioners

are

installed

in

the

same

room,

use

this

setting

when

the

two

air-conditioners

are

not

operated

with

one

wireless

remote

control.

Set

the

wireless

remote

control

and

indoor

unit.

INSTALLING TWO AIR-CONDITIONERS IN THE SAME ROOM

Setting the wireless remote control

Pull out the cover and take out batteries. Disconnect the switching line next to the battery with wire cutters.

Insert batteries. Close the cover.

Setting an indoor unit

Turn off the power source, and turn it on after 1 minute. Point the wireless

remote control that was set according to the

procedure described on the left side at the unit display section and send a signal by pressing the ACL switch on the wireless

remote control.

Since the signal is sent in about 6 seconds after the ACL swit

ch

is pressed, point the wireless

remote control at the unit display

section for

some time.

Check that the reception buzzer sound "pip" is emitted from the

indoor unit. At completion of the setting, the indoor unit emits a buzzer so

und

"pip". (If no reception tone is emitted, start the setting from

the

beginning again.)

• Forced cooling operation

Turn

off power source. Turn on power source again after a while. The

n, press the

ON/O

FF button continuously for at least 5 seconds. (The operation

will start.)

Connect charge hose to check joint of outdoor unit. Liquid side : Close the liquid valve with hexagon wrench key. Gas side : Fully open the gas valve. Carry out cooling operation. (If indoor temperature is low, ope

rate

forced cooling operation.) After low pressure gauge become 0.01MPa, stop cooling operation

and close the gas valve.

<How to pump down>

○

In order to protect the environment, be

s

ure to pump down (recovery of refrigerant).

○

Pump down is the method of recoverin

g

refrigerant from the indoor unit to the

outdoor unit when the pipes are removed from the unit.

HOW TO RELOCATE OR DISPOSE OF THE UNIT

Unit ON/OFF button

INSTALLATION TEST CHECK POINTS

After installation

Power cables and connecting wires are securely fixed to the ter

minal block.

(Both indoor and outdoor)

Power source voltage is correct as the rating.

The drain hose is fixed securely.

Service valve is fully open.

No gas leaks from the joints of the service valve.

The pipe joints for indoor and outdoor pipes have been insulate

d.

The screw of the control lid is tightened securely.

Test run

Operation of the unit has been explained to the customer. (Thre

e-minutes restart preventive timer)

When the air-conditioner is restarted or when changing the oper

ation, the unit will not start operating

for approximately 3 minutes. This is to protect the unit and it

is not a malfunction.

The wireless remote control is normal.

Protective functions are not working.

Water drains smoothly.

No abnormal noise.

Air-conditioning operation is normal.

Check the following points again after completion of the instal

lation, and before turning on the power. Conduct a test run aga

in and ensure that the unit operates properly.

Explain to the customer how to use the unit and how to take car

e of the unit following the installation manual.

○

Secure the suspensi

on bolts firmly following the

illustrations and other

instructions

.

Reception

pip

⑨

⑨

F

G

H

G

A

B

660 860

13

12

13

8

7

Pipe cover (Prepare on site)

Supporting fixture

Supporting metal

Air vent

No bump

No trap

Not touching the water

T

rapped air will generate noises.

Insulation material

1.5m~2m

Descending slope greater than 1/100

○

Conduct a drainage test after completion of the electrical wor

k and piping work.

○

During the trial, make sure that drain flows properly through t

he piping and that no water

leaks from connections.

○

In case of a new building, conduct the test before it is furni

shed with the ceiling.

○

Be sure to conduct this test even when the unit is installed in

the heating season.

(1)

Supply about 1000 cc of water to the unit through the air outl

et by using a feed water pump.

(2)

Check the drain while cooling operation.

Drain test

Procedures of drain test

7

(1)

(3)

(2)

(5) (6)

(4)

48

×

75mm

(1) (2)

(1) (2)

(3)

(3)

(1) (2)

(1) (2)

(3)

E

Copper pipe diameter

Use a flare tool designed for R410A or a conventional flare too

l.

Note that measurement B (protrusion from the flaring block) wil

l vary depending on the type of

a flare tool in use. If a conventional flare tool is used, use a copper pipe gauge o

r a similar instrument to check

protrusion so that you can keep measurement B to a correct valu

e.

Clutch type flare tool for R410A

Conventional (R22) flare tool

ø6.35

ø12.7

0.0 - 0.5

0.0 - 0.5

1.0 - 1.5

1.0 - 1.5

1.5 - 2.0

2.0 - 2.5

ø9.52

0.0 - 0.5

1.0 - 1.5

1.5 - 2.0

Measurement B (mm)

Clutch type

Wing nut type

Earth wire shall be Yellow/Green (Y/G) in color and longer than other AC wires for safety reason.

Be sure to connect

securely.

Terminal block

Wiring Clamp

The screw of the lid is tightened securely

Control Lid

Connecting wire

Wiring of the remote control signal receiver