-

96

-

'17 • SCM-T-225

RFB012A007

(8

60

)

10

3.

5

72

6

30

.5

25

.5

585

5

585

595

(60

0)

30

.5

(2

38

)

19

8

18

5

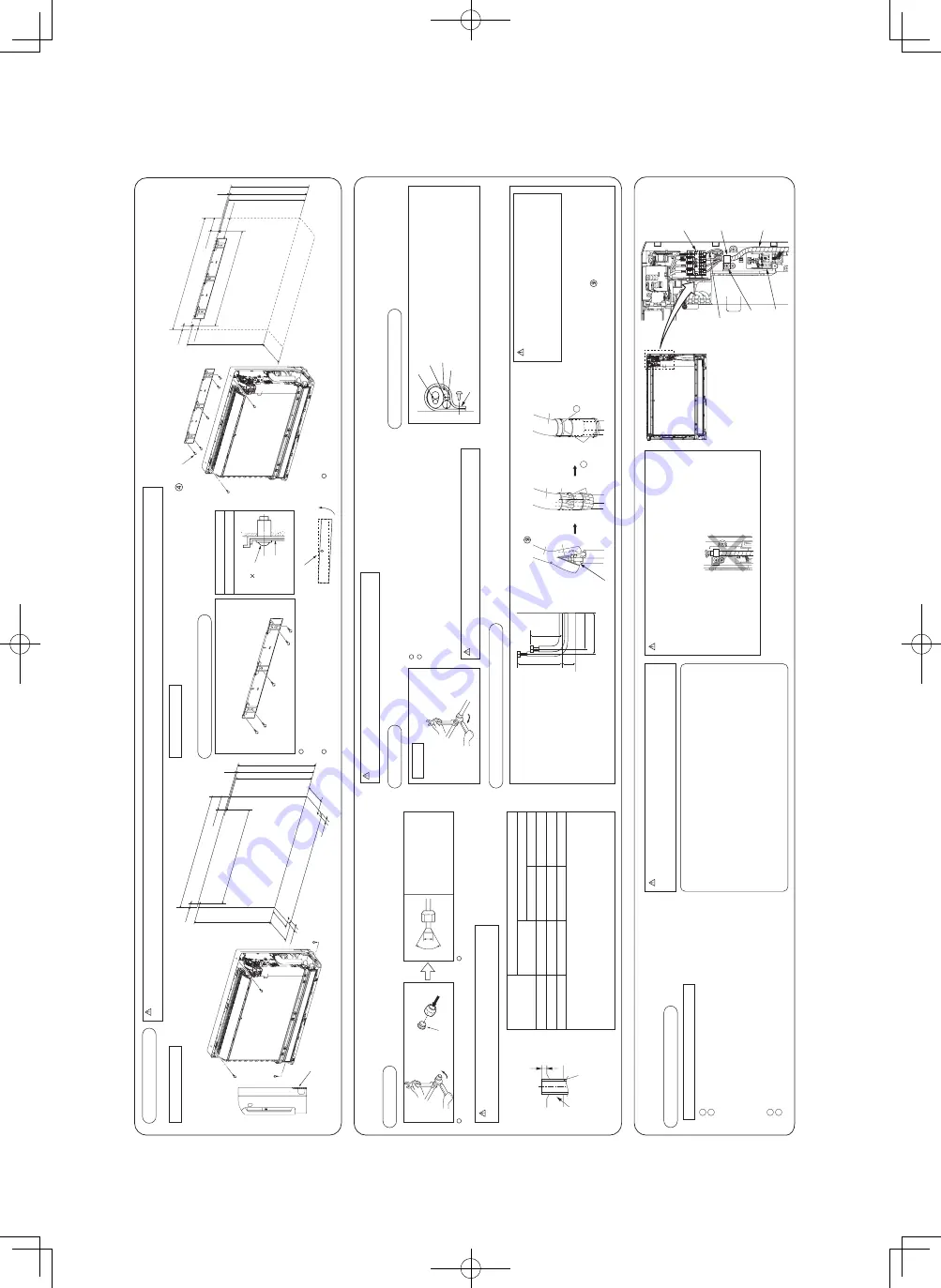

Installation of Installation boa

rd

Fixing on conc

rete wall

Use of nut anchor

Installation

boa

rd

Bolt

(M6 12)

Standa

rd hole

Fixing of indoor unit

Floor installation

W

all installation

Tapping sc

rew

(860

)

103.5

156

.5

726

585

5

585

595

(600)

30

.5

83.5

(238)

CAUTION

• During the installation, do not lean on the control box or th

e display, as they may be damaged.

• Install the indoor unit on flat wall. If improperly installed

, it may cause abnormal noise and vibration. (Distortion on the

wall shall be no larger than 3 mm.)

Secure using upper 2 screws for floor installations.

If possible, also attach two lower screws.

A

t f

irs

t s

ec

ur

e

th

e

in

sta

llat

io

n

bo

ar

d

us

in

g

5

sc

re

w

s

an

d

th

e

in

doo

ru

ni

tu

si

ng

2

sc

re

w

s.

Look for the inside wall structures (Intersediats support or pillar and finally install the unit after level surface has been checked.)

When practicing the half-console, make su

re to fix the unit secu

rely.

Otherwise, it could fall.

Adjustment of the installation boa

rd in the

horizontal di

rection is to be conducted with five

sc

rews in a temporary tightened state.

Adjust so the boa

rd will be level by tu

rning the

boa

rd with the standa

rd hole as the cente

r.

If the

re is an obstacle such as a

cable cove

r, cut o

ff the hatched

part befo

re installation.

Refrigerant pipe

Slit

Refrigerant pipe

Slit

Tape

Refrigerant pipe

155

45

105

130

140

CONNECTION OF REFRIGERANT PIPINGS

P

reparation

Indoor

(Do not tu

rn)

P

ress

Remove

90

±

0.5˚

Dimension A (mm)

Liquid side ø6.35 : 9.1

Gas side

ø9.52 : 13.2

ø12.7 : 16.6

Measu

rement B

Flaring block

Copper pipe

Connection

Finishing work and fixing

Insulation of the connection portion

Indoor

Liquid side

Gas side

(Do not tu

rn)

Connection wiring, Earth wiring

Outer tape

Refrigerant piping

Drain hose

W

ood sc

rew

Clamp

Install the removed flared nuts to the pipes to

be connected, then flared the pipes.

Remove the flared nuts. (on both liquid and

gas sides)

CAUTION

Do not apply refrigerating machine oil to the flared surface.

CAUTION

• Flaring work

Copper pipe

diameter

Clutch type flare

tool for R410A

Conventional (R22) flare tool

ø6.35

ø9.52

ø12.7

0.0 - 0.5

0.0 - 0.5

0.0 - 0.5

1.0 - 1.5

1.0 - 1.5

1.0 - 1.5

1.5 - 2.0

1.5 - 2.0

2.0 - 2.5

Measurement B (mm)

Clutch typ

e

Wing nut type

Use a flare tool designed for R410A or a conventional flare too

l.

Please note that measurement B (protrusion from the flaring blo

ck)

will vary depending on the type of a flare tool in use. If a conventional flare tool is used, please use a copper pipe

gauge

or a similar instrument to check protrusion so that you can kee

p

measurement B to a correct value.

Keep the openings of the pipes cove

red with tapes etc.

to p

revent dust, sand, etc. f

rom entering them.

Connect the pipes on both liquid and gas sides.

Tighten the nuts to the following to

rque.

Liquid side (ø6.35) : 14.0 - 18.0 N·m (1.4 - 1.8 kgf·m)

Gas side (ø9.52)

: 34.0 - 42.0 N·m (3.4 - 4.2 kgf·m)

(ø12.7)

: 49.0 - 61.0 N·m (4.9 - 6.1 kgf·m)

CAUTION

Do not apply excess to

rque to the fla

red nuts.

Otherwise, the fla

red nuts may check depending.

CAUTION

Be ca

reful not to st

ress the connecting

refrigerant

pipes. (Do not pull with a fo

rce of larger than 5 kgf.)

Cover the exterior portion with

outer tape and shape the piping

so it will match the contours of

the route that the piping to take.

Also fix the wiring and pipings to

the wall with clamps.

ELECTRICAL WIRING WORK

P

reparation of indoor unit

Terminal block

Sensor

Fixing sc

rew

Clamp

Wiring holder

Remove the fixing screw of clamp.

Connect the connecting wire securely to the terminal block.

1) Connect the connection wire securely to the terminal

block. If the wire is not affixed completely, contact will be

poor, and it is dangerous as the terminal block may heat

up and catch fire.

2) Take care not to confuse the terminal numbers for indoor

and outdoor connections.

Fix the connecting wire by wiring clamp.

Pass the connecting wire through the wiring holder.

1

2

3

4

H05RNR4G1.5 (example) or 245IEC57

H

05

R

N

R

4 or 5

G

1.5

Harmonized cable type

300/500 volts

Natural-and/or synth, rubber wire insulation

Polychloroprene rubber conductors insulation

Stranded core

Number of conductors

One conductor of the cable is the earth conductor

(yellow/green)

Section of copper wire (mm

2

)

Mounting of connecting wires

In case of faulty wiring connection, the indoor unit stops, and

then

the run lamp tu

rns on and the timer lamp blinks.

CAUTION

• During installation, do not lean on the control box or the

display, as they may be damaged.

• Pass the connecting wire securely through the wiring holder.

If it passeson the sensor, it may not detect suction

temperature and/or humidity.

• Earth wi

re shall be

Yellow/G

reen (Y/G)

in color and longer than other AC wi

res

for safety

reason.

• Cover the indoor unit’s flare-connected joints, after

they are checked for a gas leak, with an indoor unit

heat insulating material and then wrap them with a

tape with an attached pipe cover placed over the

heat insulating material’s slit area.

Use cables for interconnection wiring to avoid loosening of the

wires.

CENELEC code for cables Required field cables.

Pass the

refrigerant pipe

th

rough the piping hole to

indoor side. Arrange the pipes acco

rding

to the di

rection of piping.

Cover the coupling with insulator and then cover it with tapes.

Use an attached pipe cover for heat insulation.

Position it so that the slit a

rea faces upwa

rd.

Add

band

10

Pipe cover

9

CAUTION

If heat insulation is insu

fficient, water leakage may

occu

r. In addition, the

room temperatu

re sensor

may give a false alert due to heat radiation f

rom

the pipes.

• Forced cooling operation

Turn on a power source again after a while after turn off a power source.

Then press continually the ON/OFF button 5 seconds or more.

Conventionally,

operate

the

wireless

remote

control

by

holding

in

your

hand.

Avoid

installing

it

on

a

clay

wall

etc.

INSTALLATION OF WIRELESS REMOTE CONTROL

Mounting method of battery

Fixing to pillar or wall

CAUTION

Do not use new and

old batteries together.

Wood screws

ø3.5 X 16

Wireless remote control

2

5

Cover

Battery

6

INSTALLATION TEST CHECK POINTS

After installation

The power source voltage is correct as the rating.

No gas leaks from the joints of the service valve.

Power cables and crossover wires are securely fixed to the term

inal board.

The screw of the lid is tightened securely.

Test run

Air-conditioning operation is normal.

No abnormal noise.

Water drains smoothly.

Protective functions are not working.

The wireless remote control is normal.

Operation of the unit has been explained to the customer. (Thre

e-minutes restart preventive timer)

When the air-conditioner is restarted or when changing the oper

ation, the unit will not start operating

for approximately 3 minutes. This is to protect the unit and it

is not a malfunction.

Service valve is fully open.

The pipe joints for indoor and outdoor pipes have been insulated.

Check the following points again after completion of the instal

lation, and before turning on the power. Conduct a test run aga

in and ensure that the unit operates properly.

At the same time, explain to the customer how to use the unit a

nd how to take care of the unit following the user’s manual.

Connect charge hose to service port of outdoor unit.

Liquid side : Close the service valve with hexagon w

rench key.

Gas side : Fully open the service valve

Carry out cooling operation. (If indoor temperatu

re is lo

w

,

operate fo

rced cooling operation.)

After low p

ressu

re gauge become 0.01MPa, stop cooling

operation and close the service valve (gas side).

1

2

3

<How to pump down>

HOW TO RELOCATE OR DISPOSE OF THE UNIT

Unit ON/OFF button

In o

rder to p

rotect the envi

ronment, be su

re to pump down

(r

ecovery of

refrigerant).

Pump down is the method of

recovering

refrigerant f

rom the

indoor unit to the outdoor unit when the pipes a

re

removed

fr

om the unit.

Uncover

the

wireless

remote

control,

and

mount

the

batteries

[R03

(AAA,

Micro),

×

2

pieces]

in

the

body

regularly.

(Fit

the

poles

with

the

indication

marks,

+

&

-

without

fail)

CONCERNING TERMINAL

CONNECTION FOR AN INTERFACE

Remove the front panel and lid of control.

There is a terminal (respectively marked with CNS) for the indo

or control

board.

In connecting an interface, connect to the respective terminal

securely with

the connection harness supplied with an optional

“Interface connection kit

SC-BIKN-

E

” and fasten the connection harness onto the indoor control box

with the clamp supplied with the kit.

For more details, please refer to the user’s manual of your

“Interface

connection kit SC-BIKN-

E

”.

1

2

Install the indoor unit according to the following instructions.

Secure the upper, right, and left spaces according to the

right figure.

Do not let the horizontal bar obstruct wind from blowing out

upward/downward or reception from the wirelee remote control

.

The lattice size should be 70 % or greater of the open rate.

Cut the jumper cable (JP173) on the indoor circuit board to

control the blow-out angle.

1

2

3

4

Incor

rect installation may cause p

roblems such as non-cooling,

non-warming, and condensation water leaking into the

room.

CAUTION

Concealed installation

5cm or mo

re

5cm or mo

re

7c

m

or

m

or

e

2 - 3cm

JP171

JP170

JP172

JP173

COO

L

O

N

LY

AIR FL

O

W

SW

IT

C

H

CU

S

TO

M

A

U

TO

RE

S

TA

R

T

RE

M

O

TE

/

C

u

t

Disconnect

When

two

air

-conditioners

are

installed

in

the

same

room,

use

this

setting

when

the

two

air-

conditioners are not operated with one wireless remote control.

Set the wireless remote control

INSTALLING TWO AIR-CONDITIONERS IN THE SAME ROOM

Setting the wireless remote control

Pull out the cover and take out batteries.

Disconnect the switching line next to the battery

with wire cutters.

Insert batteries. Close the cover.

1

2

3

Setting an indoor unit

1

2

Turn off the power source, and turn it on after 1 minute.

Point the wireless remote control that was set according to the

procedure described on the left side at the indoor unit and send

a

signa

l by p

ressi

ng

th

e ACL s

wi

tc

h on the

w

ire

le

ss

remot

e

con

tro

l.

Since the signal is sent in about 6 seconds after the ACL switch

is pressed, point the wireless remote control at the indoor uni

t for

some time.

3

Check that the reception buzzer sound “pip” is emitted from the

indoor unit.

At completion of the setting, the indoor unit emits a buzzer

sound “pip”. (If no reception tone is emitted, start the settin

g

from the beginning again.)

Fitting

Do remove the air filter.

Cover the body with the front panel.

Fit the 6 latches in the lower section,

then 3 latches in the upper section.

Tighten the 5 set screws.

Fit the air filter.

Fit the air inlet panel.

1

2

3

4

5

6

To

close, attach the panel after pulling

the strings, hold the panel at both ends

of upper part to lower downwa

rd and

push it slightly until the latch works.

How to fit the f

ront panel

Close and attachment of the air inler panel

Latch

Latch

1. Open the air inlet panel and remove

the air filters.

2. Install the air-cleaning filter in the filter

holders, and then install the filter

holders in the air-conditioner.

• Each air-cleaning filter can be

installed in the upper or lower filter

holder.

3. Install the air filters and close the inlet

panel.

When installing an ai

r-

cleaning filter in the

indoor unit, be ca

reful

not to inju

re your hand

with the heat exchange

r.

CAUTION

Air-cleaning filter

7

Filter holder

8

Installing the ai

r-cleaning filters

Reception

pip

TIM

E

SE

TU

P

AC

L

A

and indoor unit.