-

90

-

'13 • SRK-T-147

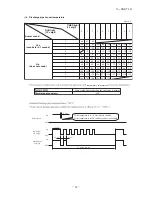

(8) Phenomenon observed after shortcircuit, wire breakage on sensor

(a) Indoor unit

Sensor

Operation

mode

Phenomenon

Shortcircuit

Disconnected wire

Room temperature

sensor

Cooling

Heating

Heat exchanger

sensor

Cooling

Heating

Humidity sensor

Cooling

Heating

■

Humidity sensor operation

Failure mode

Control input circuit resding

Air conditioning system operation

①

②

①②

①

②

Freezing cycle system protection trips and stops the compressor.

circuit

'09•SRK-DB-087D

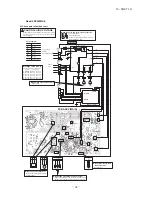

(9) Checking the indoor electrical equipment

(a) Indoor PCB check procedure

(b) Outdoor unit

Is there voltage between terminal

blocks

①

and

②

? (AC 220/230/240

V)

Indoor electrical components

are normal.

Is the voltage between terminal

blocks

②

and

③

oscillating between

DC 0 and 20V?

Inspect power source

for outdoor unit.

Replace fuse.

Replace indoor PCB.

Is the fuse burnt out? (3.15 A)

YES

YES

YES

NO

NO

NO

(b) Indoor unit fan motor check procedure

1) Indoor PCB output check

① ④

⑤

2) Fan motor resistance check

⑥

⑤

④

③

②

①

⑥

⑤

④

③

②

①

FM

I

DC15V

Indoor PCB

DC 308~336V

DC several V

(4~6 V)

CNU

(–)

GND

Blue

Yello

w

White

Black

Red

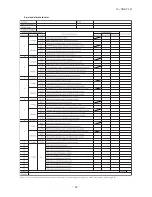

Sensor

Operation

mode

Phenomenon

Shortcircuit

Disconnected wire

Heat exchanger

sensor

Cooling

Heating

Ourdoor air

temperature sensor

Cooling

Heating

Discharge pipe

sensor

All modes

Measuring point

Resistance when normal

① − ③

−

④ − ③

−

Measuring

point

Resistance when

normal

① − ③

④ − ③

⑤ − ③

⑥ − ③

Defrosting is performed for 10 minutes at approx. 35 minutes.

Defrosting is performed for 10 minutes at approx. 35 minutes.

k

M

Compressor stop.

The compressor cannot pick up its speed owing to the current

safe so that the designed capacity is not achieved.

The compressor cannot pick up its speed owing to the heating

overload protection so that the designed capacity is not achieved.

'09•SRK-DB-087D

(9) Checking the indoor electrical equipment

(a) Indoor PCB check procedure

(b) Outdoor unit

Is there voltage between terminal

blocks

①

and

②

? (AC 220/230/240

V)

Indoor electrical components

are normal.

Is the voltage between terminal

blocks

②

and

③

oscillating between

DC 0 and 20V?

Inspect power source

for outdoor unit.

Replace fuse.

Replace indoor PCB.

Is the fuse burnt out? (3.15 A)

NO

YES

YES

NO

YES

NO

(b) Indoor unit fan motor check procedure

1) Indoor PCB output check

① ④

⑤

2) Fan motor resistance check

⑥

⑤

④

③

②

①

⑥

⑤

④

③

②

①

FM

I

DC15V

Indoor PCB

DC 308~336V

DC several V

(4~6 V)

CNU

(–)

GND

Blue

Yello

w

White

Black

Red

Sensor

Operation

mode

Phenomenon

Shortcircuit

Disconnected wire

Heat exchanger

sensor

Cooling

Heating

Ourdoor air

temperature sensor

Cooling

Heating

Discharge pipe

sensor

All modes

Measuring point

Resistance when normal

① − ③

−

④ − ③

−

Measuring

point

Voltage range when

normal

① − ③

④ − ③

⑤ − ③

Defrosting is performed for 10 minutes at approx. 35 minutes.

Defrosting is performed for 10 minutes at approx. 35 minutes.

k

M

Summary of Contents for SRK63ZMA-S

Page 2: ......

Page 3: ... 13 SRK T 147 TECHNICAL MANUAL ...

Page 11: ... 13 SRK T 147 2 Outdoor units Models SRC63ZMA S 71ZMA S RCR000Z008 ...

Page 12: ... 10 13 SRK T 147 Model SRC80ZMA S RCR000Z009 ...

Page 13: ... 11 13 SRK T 147 Model SRC92ZMA S RCR000Z010 ...

Page 14: ... 12 13 SRK T 147 3 Remote control a Wireless remote control Unit mm 60 26 167 ...

Page 55: ... 53 13 SRK T 147 page 42 Model SRC92ZMA S ...

Page 56: ... 54 13 SRK T 147 ...

Page 57: ... 55 13 SRK T 147 ...

Page 58: ... 56 13 SRK T 147 ...

Page 108: ... 106 13 SRK T 147 3 Super link E board SC ADNA E F ...

Page 109: ... 107 13 SRK T 147 ...

Page 110: ... 108 13 SRK T 147 ...

Page 115: ... 113 13 SRK T 147 ...

Page 121: ... 119 13 SRK T 147 ...

Page 127: ... 125 13 SRK T 147 ...

Page 133: ... 131 13 SRK T 147 ...

Page 148: ... 146 13 SRK T 147 CRBE0347 5 14 15 13 13 15 16 2 3 4 6 12 15 9 10 7 11 15 15 8 1 PANEL ASSY ...