-

-

'17 • SRK-T-206

○

Conventionally, operate the

wireless remote control by holding

in your hand.

○

Avoid installing it on a clay wall etc

.

⑤

W

ood screws

ø3.5 X 16

②

Wireless

remote contro

l

⑥

Battery

Cove

r

○

Removing

○

Installing

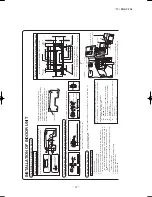

How to remove and install the front pane

l

①

Remove the 2 set screws.

②

Remove the 3 latches in the upper

section. And take off the front panel.

①

Cover the body with the front panel.

And lock the latches (on the base).

②

Tighten the 2 set screws.

③

Carry out in the above order.

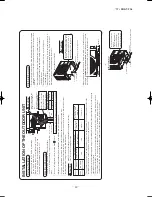

SELECTION OF INSTALLATION LOCATION

Indoor uni

t

Outdoor uni

t

(Install at location that meets the following conditions, after getting approval from the customer

)

○

Where there is no obstructions to the air flow and where the cooled and heated air can be evenly distributed.

○

A solid place where the unit or the wall will not vibrate.

○

A place where there will be enough space for servicing. (Where space mentioned right can be secured)

○

Where wiring and the piping work will be easy to conduct.

○

The place where receiving part is not exposed to the direct rays of the sun or the strong rays of the street

lighting.

○

A place where it can be easily drained.

○

A place separated at least 1m away from the TV or the radio. (To prevent interference to images and

sounds.)

○

Places where this unit is not affected by the high frequency equipment or electric equipment.

○

Avoid installing this unit in place where there is much oil mist.

○

Places where there is no electric equipment or household under the installing unit.

○

Install the indoor unit on the wall where the height from the floor to the bottom of the unit is more than 1.8m.

○

A place where the air-conditioner can be received the signal surely during operating the wireless remote

control.

○

Places where there is no affected by the TV and radio etc.

○

Do not place where exposed to direct sunlight or near heat devices such as a stove.

○

Where

air

is

not

trapped.

○

Where

the

installation

fittings

can

be

firmly

installed.

○

Where

wind

does

not

hinder

the

intake

and

outlet

pipes.

○

Out

of

the

heat

range

of

other

heat

sources.

○

A

place

where

stringent

regulation

of

electric

noises

is

not

applicable.

○

Where

it

is

safe

for

the

drain

water

to

be

discharged.

○

Where

noise

and

hot

air

will

not

bother

neighboring

residents.

○

Where

snow

will

not

accumulate.

○

Where

strong

winds

will

not

blow

against

the

outlet

pipe.

○

When the unit is installed, the space of the following dimension and above shall be secured.

In case the barrier is 1.2m or above in height, or is overhead, the sufficient space between

the unit and wall shall be secured.

Do

not

install

the

unit

in

places

which

exposed

to

sea

breeze

(e.g.

coastal

area)

or

calcium

chloride

(e.g.

snow

melting

agent),

exposed

to

ammonia

substance

(e.g.

organic

fertilizer).

INSTALLATION OF WIRELESS REMOTE CONTROL

Mounting method of battery

Fixing to pillar or wall

RLC012A011C

WALL TYPE AIR-CONDITIONE

R

R410A REFRIGERANT USE

D

○

Pull

out

the

cover

and

mount

the

batteries

[R03

(AAA,

Micro),

×

2

pieces]

in

the

body

regularly.

(Fit

the

poles

with

the

indication

marks,

+

&

−

without

fail)

○

Do not use new and old

batteries together

.

①

Remove the air inlet panel,

lid and front panel.

②

Remove the control cover.

(Remove the screw.)

③

Cut jumper wire J2 (marked

CUSTOM on the PCB) on

the indoor control board. Do

not allow the cut wires to

contact any other wiring.

④

Install the control box, lid

and front panel.

INSTALLING TWO AIR-CONDITIONERS IN THE SAME ROOM

Setting the wireless remote contro

l

Setting an indoor unit

①

Pull out the cover and take out

batteries.

②

Disconnect the switching line next

to the battery with wire cutters

.

③

Insert batteries. Close the cover.

②

Wireless remote control

The screw of the

service panel is

tightened securely

.

⑤

W

ood screws

③

Remote control holder

Service panel for

electrical parts

①

Installation board

5 cm minimum

from the wall

10 cm minimum

from the wall

6.5 cm minimum from the ceiling

Sleeve

(sold separately)

CAUTION

Completely seal the hole on

the wall with putty. Otherwise,

furniture, or other, may be

wetted by leaked water or

dewing.

putty

putty

Indoor side

Outdoor side

EARTHING WORK

○

Earth work shall be carried out without fail in order to prevent

electric shock and noise generation.

○

The connection of the earth cable to the following substances

causes dangerous failures, therefore it shall never be done.

City water pipe, Town gas pipe, TV antenna, lightning

conductor, telephone line, etc

.

HOW TO RELOCATE OR DISPOSE OF THE UNIT

○

In order to protect the environment, be sure

to pump down (recovery of refrigerant).

○

Pump down is the method of recovering

refrigerant from the indoor unit to the

outdoor unit when the pipes are removed

from the unit.

<How to pump down>

①

Connect charge hose to check joint.

②

Liquid side : Close the liquid valve with hexagon wrench key.

Gas side : Fully open the gas valve.

Carry out cooling operation. (If indoor temperature is low,

operate forced cooling operation.)

③

After low pressure gauge become 0.01MPa, stop cooling

operation and close the gas valve.

●

Forced cooling operation

Turn off power source. Turn on

power source again after a while.

Then, press the ON/OFF button

continuously for at least 5 seconds.

(The operation will start.)

Wireless remote control

Limitation of the piping lengt

h

Model

Total one way length

V

ertical height dif

ference

Additional refrigeran

t

SRK35, DXK12

MAX. 15m

MAX. 10m

Not require

d

SRK45, DXK15

MAX. 25m

MAX. 15

m

Less than 15m : Not required More than 15

m

: 20g/m

SRK17-25, DXK05-09

MAX. 15m

MAX. 10

m

Less than 10m : Not required More than 10

m

: 20g/m

W

ARNING

CAUTION

•

Carr

y out the electrical work for ground lead with care.

Do not connect the ground lead to the gas line, water line, lightning conductor or telephone line’

s ground lead. Incorrect gro

unding can cause unit faults such as electric shocks due to short-circuiting.

•

Installation must be carried out by the qualified installer

.

If you install the system by yourself, it may cause serious trouble such as water leaks, electric shocks, fire and personal injur

y, as a result of a system malfunction. Do not carr

y

out the installation and maintenance work except the by qualified installer

.

•

Install the system in full accordance with the installation manual.

In

co

rre

ct

in

st

al

la

tio

n

m

ay

c

au

se

b

ur

st

s,

p

er

so

na

l i

nj

ur

y,

wa

te

r l

ea

ks

, e

le

ct

ric

s

ho

ck

s

an

d

fir

e.

•

Be sure to use only for household and residence.

If this appliance is installed in inferior environment such as machine shop etc., it can cause malfunction.

•

Use the original accessories and the specified components for installation.

If parts other than those prescribed by us are used, It may cause water leaks, electric shocks, fire and personal injur

y.

•

Install the unit in a location with good support.

Unsuitable installation locations can cause the unit to fall resulting in material damage and personal injur

y.

•

Ensure the unit is stable when installed, so that it can withstand earthquakes and strong winds.

Unsuitable installation locations can cause the unit to fall and cause material damage and personal injur

y.

•

Ventilate the working area well in the event of refrigerant leakage during installation.

If the density of refrigerant exceeds the limit, consult the dealer and install the ventilation system, other

wise lack of oxygen can occur

, which can cause serious accident.

•

When installing in small rooms, take prevention measures not to exceed the density limit of refrigerant in the event of leakage, referred by the formula (accordance with ISO5149).

If

th

e

de

ns

ity

o

f r

ef

rig

er

an

t e

xc

ee

ds

th

e

lim

it,

c

on

su

lt

th

e

de

al

er

a

nd

in

st

al

l t

he

v

en

til

at

io

n

sy

st

em

, o

th

er

wi

se

la

ck

o

f o

xy

ge

n

ca

n

oc

cu

r,

wh

ic

h

ca

n

ca

us

e

se

rio

us

a

cc

id

en

t.

•

Af

te

r c

om

pl

et

in

g

in

st

al

la

tio

n,

c

he

ck

th

at

n

o

re

fri

ge

ra

nt

le

ak

s

fro

m

th

e

sy

st

em

.

If refrigerant leaks into the room and comes into contact with an oven or other hot surface, poisonous gas is produced.

•

Use the prescribed pipes, flare nuts and tools for R410A.

Using existing parts (for R22 or R407C) can cause the unit failure and serious accidents due to burst of the refrigerant circuit.

•

Tighten the flare nuts by torque wrench with specified method.

If the flare nut were tightened with excess torque, this may cause burst and refrigerant leakage after a long period.

•

Do not open the ser

vice valves for liquid line and gas line until completed

refrigerant piping work, air tightness test and evacuation.

If the compressor is operated in state of opening ser

vice valves before completing

connection of refrigerant piping work, air can be sucked into refrigerant circuit, which can cause burst or personal injur

y due to anomalously high pressure in the refrigerant.

•

The electrical installation must be carried out by the qualified electrician in accordance with “the norm for electrical work” and “national wiring regulation”, and the system must be connected to the dedicated circuit.

Power source with insufficient capacity and incorrect function done by improper work can cause electric shocks and fire.

•

Be sure to shut off the power before starting electrical work.

Failure to shut off the power can cause electric shocks, unit failure or incorrect function of equipment.

•

Be sure to use the cables conformed to safety standard and cable ampacity for power distribution work.

Unconformable cables can cause electric leak, anomalous heat production or fire.

•

Th

is

a

pp

lia

nc

e

m

us

t b

e

co

nn

ec

te

d

to

m

ai

n

po

w

er

s

ou

rc

e

by

m

ea

ns

o

f a

ci

rc

ui

t b

re

ak

er

o

r s

w

itc

h

(fu

se

:1

6A

) w

ith

a

c

on

ta

ct

s

ep

ar

at

io

n

of

a

t l

ea

st

3m

m

.

•

When plugging this appliance, a plug conforming to the norm IEC60884-1 must be used.

•

Use the prescribed cables for electrical connection, tighten the cables securely in terminal block and relieve the cables correctly to prevent overloading the terminal blocks.

Loose connections or cable mountings can cause anomalous heat production or fire.

•

Arrange the wiring in the control box so that it cannot be pushed up further into the box. Install the ser

vice panel correctly

.

Incorrect installation may result in overheating and fire.

•

Be sure to fix up the ser

vice panels.

Incorrect fixing can cause electric shocks or fire due to intrusion of dust or water

.

•

Be sure to switch off the power source in the event of installation, inspection or ser

vicing.

If the power source is not shut off, there is a risk of electric shocks, unit failure or personal injur

y due to the unexpected start of fan.

•

Stop the compressor before removing the pipe after shutting the ser

vice

valve on pump down work.

If the pipe is removed when the compressor is in operation with the ser

vice valve open,

air would be mixed in the refrigeration circuit and it could cause explosion and injuries due to abnormal high pressure in the cooling cycle.

•

Only use prescribed option parts. The installation must be carried out by the qualified installer

.

If you install the system by yourself, it can cause serious trouble such as water leaks, electric shocks, fire.

•

Be sure to wear protective goggles and gloves while at work.

•

Earth leakage breaker must be installed.

If the earth leakage breaker is not installed, it can cause electric shocks.

•

Do not put the drainage pipe directly into drainage channels where poisonous gases such as sulphide gas can occur

.

Poisonous gases will flow into the room through drainage pipe and seriously affect the user’

s health and safety

. This can also cause the corrosion of the indoor unit and a

resultant unit failure or refrigerant leak.

•

Ensure that no air enters in the refrigerant circuit when the unit is installed and removed.

If air enters in the refrigerant circuit, the pressure in the refrigerant circuit becomes too

high, which can cause burst and personal injur

y.

•

Do not process or splice the power cord, or share the socket with other power plugs.

This may cause fire or electric shock due to defecting contact, defecting insulation and over

-current etc.

•

Do not bundle or wind or process the power cord. Do not deform the power cord by treading it.

This may cause fire or heating.

•

Do

n

ot

v

en

t R

41

0A

in

to

th

e

at

m

os

ph

er

e

: R

41

0A

is

a

fl

uo

rin

at

ed

g

re

en

ho

us

e

ga

s,

c

ov

er

ed

b

y

th

e

Ky

ot

o

Pr

ot

oc

ol

w

ith

G

lo

ba

l W

ar

m

in

g

Po

te

nt

ia

l (

GW

P)

=1

97

5.

•

Do not run the unit with removed panels or protections.

Touching rotating equipments, hot surfaces or high voltage parts can cause personal injur

y due to entrapment, burn or electric shocks.

•

Do not perform any change of protective device itself or its setup condition.

The forced operation by short-circuiting protective device of pressure switch and temperature control or the use of non specified component can cause fire or burst.

•

Use the circuit breaker for all pole correct capacity

. Circuit breaker should

be able to disconnect all poles under over current.

Using the incorrect one could cause the system failure and fire.

•

Install isolator or disconnect switch on the power source wiring in accordance with the local codes and regulations.

The isolator should be locked in OFF state in accordance with EN60204-1.

•

Be sure to install indoor unit properly according to instruction manual so that drainage can run off smoothly

.

Improper installation of indoor unit can cause dropping water into the room and damaging personal property

.

•

Install the drainage pipe to run off drainage securely according to the installation manual.

Incorrect installation of the drainage pipe can cause dropping water into the room and damaging personal property

.

•

Be sure to install the drainage pipe with descending slope of 1/100 or more, and not to make traps and air

-bleedings.

Check if the drainage runs off securely during commissioning and ensure the space for

inspection and maintenance.

•

After maintenance, all wiring, wiring ties and the like, should be returned to their original state and wiring route, and the necessar

y clearance from

all metal parts should be secured.

•

Secure a space for installation, inspection and maintenance specified in the manual.

Insufficient space can result in accident such as personal injur

y due to falling from the

installation place.

•

Take care when carr

ying the unit by hand.

If the unit weights more than 20kg, it must be carried by two or more persons. Do not carr

y by the plastic straps, always use the carr

y handle when carr

ying the unit by hand.

Use gloves to minimize the risk of cuts by the aluminum fins.

•

Dispose of any packing materials correctly

.

Any remaining packing materials can cause personal injur

y as it contains nails and

wood. And to avoid danger of suffocation, be sure to keep the plastic wrapper away from children and to dispose after tear it up.

•

For installation work, be careful not to get injured with the heat exchanger

,

piping flare portion or screws etc.

•

Be sure to insulate the refrigerant pipes so as not to condense the ambient air moisture on them.

Insufficient insulation can cause condensation, which can lead to moisture damage on the ceiling, floor

, furniture and any other valuables.

•

W

he

n

pe

rfo

rm

th

e

ai

r-c

on

di

tio

ne

r o

pe

ra

tio

n

(c

oo

lin

g

or

d

eh

um

id

ify

in

g

op

er

at

io

n)

in

w

hi

ch

v

en

til

at

or

is

in

st

al

le

d

in

th

e

ro

om

. I

n

th

is

c

as

e,

u

si

ng

th

e

ai

r-c

on

di

tio

ne

r

in

p

ar

al

le

l

w

ith

t

he

v

en

til

at

or

,

th

er

e

is

t

he

p

os

si

bi

lit

y

th

at

d

ra

in

w

at

er

m

ay

ba

ck

flo

w

in

a

cc

or

da

nc

e

w

ith

th

e

ro

om

la

ps

e

in

to

th

e

ne

ga

tiv

e

pr

es

su

re

s

ta

tu

s.

Th

er

ef

or

e,

s

et

u

p

th

e

op

en

in

g

po

rt

su

ch

a

s

in

co

rp

or

at

e

th

e

ai

r i

nt

o

th

e

ro

om

th

at

m

ay

a

pp

ro

pr

ia

te

to

v

en

til

at

io

n

(F

or

e

xa

m

pl

e;

O

pe

n

th

e

do

or

a

li

ttl

e)

. I

n

ad

di

tio

n,

ju

st

a

s

ab

ov

e,

s

o

se

t

up

t

he

o

pe

ni

ng

p

or

t

if

th

e

ro

om

l

ap

se

i

nt

o

ne

ga

tiv

e

pressure status due to register of the wind for the high rise apartment etc.

•

Be sure to perform air tightness test by pressurizing with nitrogen gas after completed refrigerant piping work.

If the density of refrigerant exceeds the limit in the event of refrigerant leakage in the small room, lack of oxygen can occur

, which can cause serious accidents.

•

Do not install the unit in the locations listed below

.

•

Locations where carbon fiber

, metal powder or any powder is floating.

•

Locations where any substances that can affect the unit such as sulphide gas, chloride gas, acid and alkaline can occur

.

•

Vehicles and ships.

•

Locations where cosmetic or special sprays are often used.

•

L

oc

at

io

ns

w

ith

d

ire

ct

e

xp

os

ur

e

of

o

il

m

is

t a

nd

s

te

am

s

uc

h

as

k

itc

he

n

an

d

m

ac

hi

ne

p

la

nt

.

•

Locations where any machines which generate high frequency harmonics are used.

•

Locations with salty atmospheres such as coastlines.

•

Locations with heavy snow (If installed, be sure to provide base flame and snow hood mentioned in the manual).

•

Locations where the unit is exposed to chimney smoke.

•

Locations at high altitude (more than 1000m high).

•

L

oc

at

io

ns

w

ith

a

m

m

on

ic

a

tm

os

ph

er

es

(e

.g

. o

rg

an

ic

fe

rti

liz

er

).

•

L

oc

at

io

ns

w

ith

c

al

ci

um

c

hl

or

id

e

(e

.g

. s

no

w

m

el

tin

g

ag

en

t).

•

Locations where heat radiation from other heat source can affect the unit.

•

Locations without good air circulation.

•

Locations with any obstacles which can prevent inlet and outlet air of the unit.

•

Locations where short circuit of air can occur (in case of multiple units installation).

•

Locations where strong air blows against the air outlet of outdoor unit.

•

Locations where something located above the unit could fall.

It can cause remarkable decrease in performance, corrosion and damage of components, malfunction and fire.

•

Do not install the indoor unit in the locations listed below (Be sure to install the indoor unit according to the installation manual for each model because each indoor unit has each limitation).

•

Locations with any obstacles which can prevent inlet and outlet air of the unit.

•

Locations where vibration can be amplified due to insufficient strength of structure.

•

Locations where the infrared receiver is exposed to the direct sunlight or the strong light beam (in case of the infrared specification unit).

•

Locations where an equipment affected by high harmonics is placed (TV set or radio receiver is placed within 1m).

•

Locations where drainage cannot run off safely

.

It can affect performance or function and etc.

•

Do not install the outdoor unit in the locations listed below

.

•

Locations where discharged hot air or operating sound of the outdoor unit can bother neighborhood.

•

Locations where outlet air of the outdoor unit blows directly to plants. The outlet air can affect adversely to the plant etc.

•

Locations where vibration can be amplified and transmitted due to insufficient strength of structure.

•

Locations where vibration and operation sound generated by the outdoor unit can affect seriously (on the wall or at the place near bed room).

•

Locations where an equipment affected by high harmonics is placed (TV set or radio receiver is placed within 1m).

•

Locations where drainage cannot run off safely

.

It can affect surrounding environment and cause a claim.

•

Do not install the unit near the location where leakage of combustible gases can occur

.

If leaked gases accumulate around the unit, it can cause fire.

•

Do not install the unit where corrosive gas (such as sulfurous acid gas etc.) or combustible gas (such as thinner and petroleum gases) can accumulate or collect, or where volatile combustible substances are handled.

Corrosive gas can cause corrosion of heat exchanger

, breakage of plastic parts and etc.

And combustible gas can cause fire.

•

Do not use the indoor unit at the place where water splashes may occur such as in laundries.

Since the indoor unit is not waterproof, it can cause electric shocks and fire.

•

Do not install nor use the system close to the equipment that generates electromagnetic fields or high frequency harmonics.

Equipment such as inverters, standby generators, medical high frequency equipments and telecommunication equipments can affect the system, and cause malfunctions and breakdowns. The system can also affect medical equipment and telecommunication equipment, and obstruct its function or cause jamming.

•

Do not place any variables which will be damaged by getting wet under the indoor unit.

When the relative humidity is higher than 80% or drainage pipe is clogged, condensation or drainage water can drop and it can cause the damage of valuables.

•

Do not install the remote control at the direct sunlight.

It can cause malfunction or deformation of the remote control.

•

Do not use the unit for special purposes such as storing foods, cooling precision instruments and preser

vation of animals, plants or art.

It can cause the damage of the items.

•

Do not install the outdoor unit in a location where insects and small animals can inhabit.

Insects and small animals can enter the electric parts and cause damage or fire. Instruct the user to keep the surroundings clean.

•

Do not use the base flame for outdoor unit which is corroded or damaged due to long periods of operation.

Us

in

g

an

o

ld

an

d

da

m

ag

e b

as

e f

lam

e c

an

ca

us

e t

he

u

ni

t f

all

in

g

do

wn

an

d

ca

us

e p

er

so

na

l i

nj

ur

y.

•

Do not use any materials other than a fuse with the correct rating in the location where fuses are to be used.

Co

nn

ec

tin

g

th

e

ci

rc

ui

t w

ith

c

op

pe

r w

ire

o

r o

th

er

m

et

al

th

re

ad

c

an

c

au

se

u

ni

t f

ai

lu

re

a

nd

fi

re

.

•

Do not touch any buttons with wet hands.

It can cause electric shocks.

•

Do not touch any refrigerant pipes with your hands when the system is in operation.

During operation the refrigerant pipes become extremely hot or extremely cold depending the operating condition, and it can cause burn injur

y or frost injur

y.

•

Do not touch the suction or aluminum fin on the outdoor unit.

This may cause injur

y.

•

Do not put anything on the outdoor unit and operating unit.

This may cause damage the objects or injur

y due to falling to the object.

•

Do not wash the inside of the air

-conditioner

.

W

ater leakage and permanent damage may result. Electrical hazard exists.

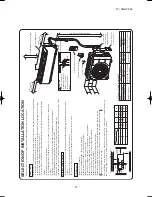

Standard accessories (installation kit)

Accessories for indoor unit

Necessary tools for the installation work

Vacuum pump

Vacuum pump adapter (Anti-reverse flow type)

(Designed specifically for R410A)

Gauge manifold

(Designed specifically for R410A)

Charge hose (Designed specifically for R410A)

Flaring tool set (Designed specifically for R410A)

Gas leak detector (Designed specifically for R410A)

Gauge for projection adjustment (Used when

flare is made by using conventional flare tool)

Pipe bender

10

11

12

13

14

15

16

17

Plus headed driver

Knife

Saw

Tape measure

Hammer

Spanner wrench

Torque wrench

[14.0

~

62.0N·m (1.4

~

6.2kgf·m)]

Hole core drill (65mm in diameter)

Wrench key (Hexagon) [4m/m]

1

2

3

4

5

6

7

8

9

Installation board

(Attached to the rear of the indoor unit)

Wireless remote control

Remote control holder

Tapping screws

(for installation board ø4 X 25mm)

Q’ty

1

1

1

5

1

2

3

4

Locally procured parts

Sealing plate

Sleeve

Inclination plate

Putty

Drain hose (extension hose)

Piping cover

(for insulation of connection piping)

Q’ty

1

1

1

1

1

1

a

b

c

d

e

f

SAFETY PRECAUTIONS

•

Befor

e installation, r

ead the “SAFETY PRECAUTIONS” car

efully and strictly follow it during the installation work in

or

der to pr

otect yourself.

•

The pr

ecautionary items mentioned below ar

e distinguished into two levels, and

.

:

W

rong installation would cause serious consequences such as injuries or death.

:

W

rong installation might cause serious consequences depending on cir

cumstances.

Both mention the important items to pr

otect your health and safety so strictly follow them by any means.

•

B

e

su

re

to

c

on

fir

m

n

o

an

om

al

y

on

th

e

eq

ui

pm

en

t b

y

co

m

m

is

si

on

in

g

af

te

r c

om

pl

et

in

g

in

st

al

la

tio

n

an

d

ex

pl

ai

n

th

e

op

er

-

at

in

g

m

et

ho

ds

a

s

w

el

l a

s

th

e

m

ai

nt

en

an

ce

m

et

ho

ds

o

f t

hi

s

eq

ui

pm

en

t t

o

th

e

us

er

a

cc

or

di

ng

to

th

e

ow

ne

r’s

m

an

ua

l.

•

Keep the installation manual together with owner’

s manual at a place wher

e any user can r

ead at any time.

Mor

eover if necessary

, ask to hand them to a new user

.

•

Befor

e starting the installation work, pr

oper pr

ecautions (using suitable pr

otective clothing, gr

oves etc.) should be

taken by qualified installer

.

•

Pay attention not to fall down the tools, etc. when installing the unit at the high position.

•

If unusual noise can be hear

d during operation, consult the dealer

.

•

The meanings of “Marks” used her

e ar

e shown as follows:

CAUTION

W

ARNING

CAUTION

W

ARNING

• Model name and power source • Refrigerant piping length • Piping, wiring and miscellaneous small parts

Check before installation work

Wood screws

(for remote control holder ø3.5 X 16mm)

Battery [R03 (AAA, Micro) 1.5V]

Grommet

Drain elbow (Heat pump type only)

2

2

Q’ty

1

1

Accessories for outdoor unit

5

6

7

8

Never do it under any

cir

cumstances.

Always do it accor

ding to the

instruction.

INSTALLATION MANUAL

•

While install the unit, be sur

e to check the selection of installation place,

power sour

ce specifications, usage limitation (piping length, height dif

fer

ences

between indoor and outdoor units, power sour

ce voltage etc.) and installation

spaces.

Set screw

s

Unit ON/OFF butto

n

Latche

s

180 cm minimum from the floor

When two air-conditioners are installed in the same room, use this setting when the two air-conditioners are not

operated with one wireless remote control. Set the remote control and indoor unit.

Disconnec

t

Jumper wire (J2) custo

m

Intake

The

height

of

a

wall

is

1200mm

or

less.

(

service space

)

Intake

Outlet

L

3

L

2

L

4

L

1

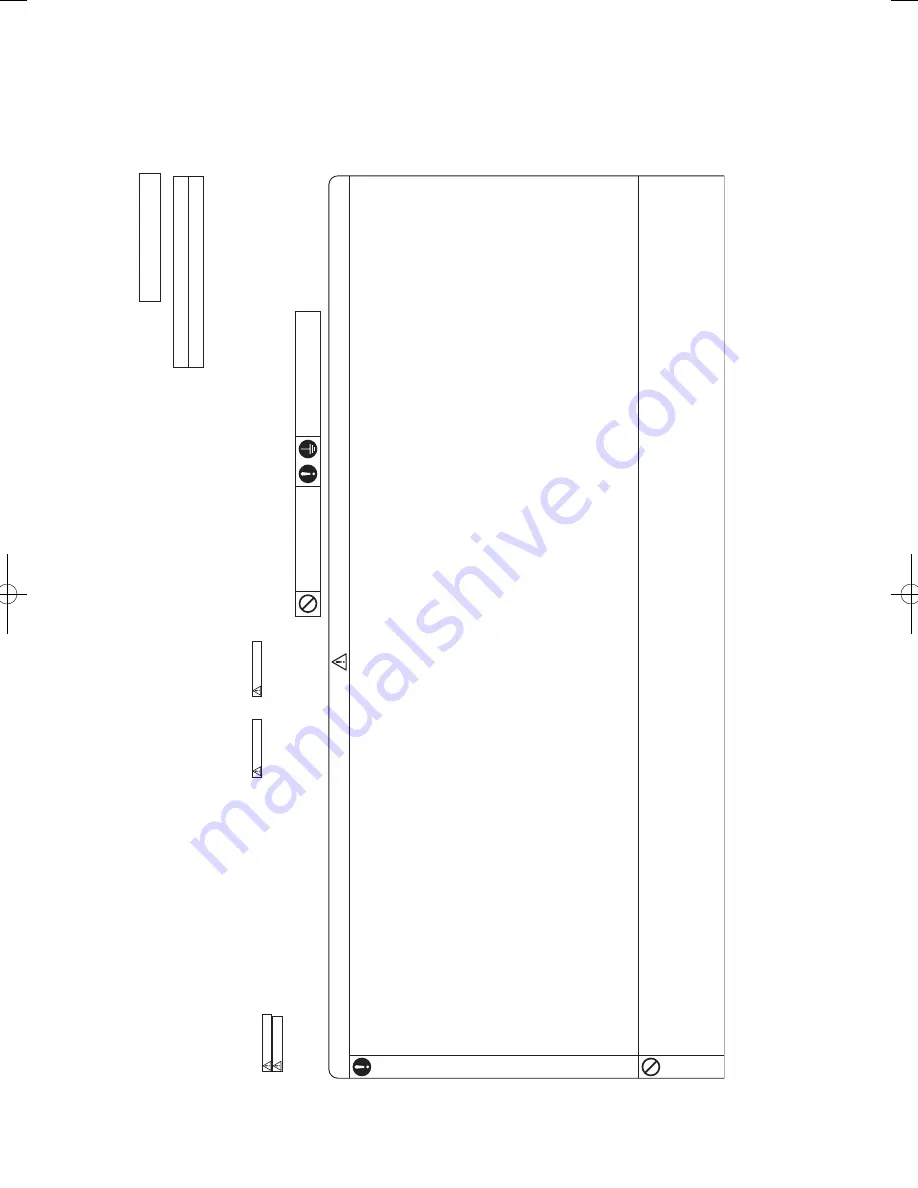

Example installation

Size

L1

L2

L3

L4

Open

100

100

250

280

100

80

Open

280

Open

80

250

180

Open

80

Open

(mm)

I

II

III

IV

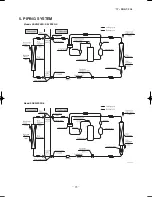

8. APPLICATION DATA

(1) Models SRK20ZSPR-S, 25ZSPR-S, 35ZSPR-S, 45ZSPR-S

RLC012A011

17-SRK-T206_001-062.indd 43

2017/01/17 17:53:23