-

-

'17 • SRK-T-206

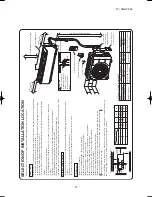

Wires for connecting indoor and outdoor units

Exterior tape

Gas piping

Insulation

Liquid piping

Band (procured locally)

Pipe cover (procured locally)

8) Heating and condensation prevention

Take

care

so

that

installed

pipes

may

not

touch

components

within

a

unit.

If

pipes

touch

internal

components,

abnormal

sounds

and/or

vibrations.

4) On-site piping work

IMPORTANT

How to remove the side cover

Remove

the

screw

of

the

side

cover

and

remove

to

the

front.

A

B

Flared

pipe

end

:

A

(mm)

ø6.35

ø12.7

ø15.88

Copper

pipe

outer diameter

0 A –04

9.1

16.6

19.7

ø6.35

ø12.7

ø15.88

Copper

pipe

outer diameter

0

-

0.5

1.

0

-

1.5

Copper

pipe

protrusion

for

flaring

:

B

(mm)

In

the

case

of

a

rigid

(clutch)

type

With

an

R410A

tool

With

a

conventional

tool

CAUTION

Do

not

apply

force

beyond

proper

fastening

torque

in

tightening

the

flare

nut.

Tightening angle (

°

)

Tightening torque (N·m)

ø6.35 (1/4")

ø12.7 (1/2")

ø15.88 (5/8")

Recommended length of a tool handle (mm)

Service valve size (mm)

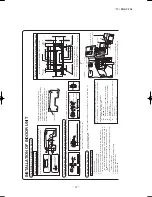

5) Air tightness test

Gas side service valve

Check joint

Pressurize

Close

Outdoor unit

Indoor unit

<Work flow>

6) Evacuation

Pay attention to the following points in addition to the above for the R410A and compatible machines.

Air tightness test completed

Fill refrigerant

Vacuum gauge check

Vacuuming completed

Vacuuming begins

3)

Refrigerant

pipe

wall

thickness

and

material

NOTE

*Phosphorus deoxidized seamless copper pipe ICS 23.040.15, ICS 77.150.30

ø6.35

0.8

O-type pipe

ø12.7

0.8

O-type pipe

ø15.88

1.0

O-type pipe

Pipe diameter [mm]

Minimum pipe wall thickness [mm]

Pipe material*

UÊ

-iiVÌÊ

ÀivÀ}iÀ>ÌÊ

««iÃÊ

vÊ

Ì iÊ

Ì>LiÊ

à ÜÊ

Ê

Ì iÊ

À} ÌÊ

Ü>Ê

Ì ViÃÃÊ

>`Ê

>ÌiÀ>Ê

>ÃÊ

ëiVvi`Ê

for

each

pipe

size.

Although outdoor and indoor units themselves have been tested for air tightness at the factory, check the connecting pipes afte

r the installation work for air tightness from the service valve’s

check joint equipped on the outdoor unit side. While conducting a test, keep the service valve shut all the time. a)

Raise

the

pressure

to

0.5MPa,

and

then

stop.

Leave

it

for

five

minutes

to

see

if

the

pressure

drops.

b)

Then

raise

the

pressure

to

1.5MPa,

and

stop.

Leave

it

for

five

more

minutes

to

see

if

the

pressure

drops.

c)

Then

raise

the

pressure

to

the

specified

level

(4.15MPa),

and

record

the

ambient

temperature

and

the

pressure.

d)

If

no

pressure

drop

is

observed

with

an

installation

pressurized

to

the

specified

level

and

left

for

about

one

day,

it

is

acceptable.

When

the

ambient

temperature

fall

1

C,

the

pressure

also

fall

approximately

0.01MPa.

The

pressure,

if

changed,

should

be

compensated

for.

e)

If

a

pressure

drop

is

observed

in

checking

e)

and

a)

–

d),

a

leak

exists

somewhere.

Find

a

leak

by

applying

bubble

test

liquid

to

welded

parts

and

flare

joints

and

repair

it.

After

repair,

conduct

an

air

tightness

test

again.

In

conducting

an

air

tightness

test,

use

nitrogen

gas

and

pressurize

the

system

with

nitrogen

gas

from

the

gas

side.

Do

not

use

a

medium

other

than

nitrogen

gas

under

any

circumstances.

UÊ

>ÀÀÞÊ

ÕÌÊ

Ì iÊ

Ê

ÃÌiÊ

««}Ê

ÜÀÊ

ÜÌ Ê

Ì iÊ

ÃiÀÛViÊ

Û>ÛiÊ

vÕÞÊ

VÃi`°

UÊ

ÛiÊ

ÃÕvvViÌÊ

«ÀÌiVÌÊ

ÌÊ

>Ê

««iÊ

i`Ê

V«ÀiÃÃi`Ê

>`Ê

L>âi`]Ê

ÀÊ

ÜÌ Ê

>Ê

adhesive

tape)

so

that

water

or

foreign

matters

may

not

enter

the

piping.

UÊ

i`Ê

>Ê

««iÊ

ÌÊ

>Ê

À>`ÕÃÊ

>ÃÊ

>À}iÊ

>ÃÊ

«À>VÌV>Ê

,£ä

0-

R150).

Do

not

bend

a

pipe

repeatedly

to

correct

its

form.

UÊ

>ÀiÊ

ViVÌÊ

ÃÊ

ÕÃi`Ê

LiÌÜiiÊ

Ì iÊ

ÕÌÊ

>`Ê

ÀivÀ}iÀ>ÌÊ

««i°Ê

>ÀiÊ

>Ê

««iÊ

>vÌiÀÊ

engaging

a

flare

nut

onto

it.

Flare

dimensions

for

R410A

are

different

from

those

for

conventional

R407C.

Although

we

recommend

the

use

of

flaring

tools

designed

specifically

for

R410A,

conventional

flaring

tools

can

also

be

used

by

adjusting

the

measurement

of

protrusion

B

with

a

protrusion

control

gauge.

UÊ

/ iÊ

««iÊ

à Õ`Ê

LiÊ

>V Ài`Ê

iÛiÀÞÊ

£°xÊ

ÀÊ

iÃÃÊ

ÌÊ

Ã>ÌiÊ

Ì iÊ

ÛLÀ>Ì°Ê

UÊ

/} ÌiÊ

Ì iÊ

v>ÀiÊ

ÌÊ

ÃiVÕÀiÞÊ

ÜÌ Ê

>Ê

`ÕLiÊ

ë>iÀ°Ê

UÊ

/Ê

«ÀiÛiÌÊ

>Ê

`vviÀiÌÊ

Ê

vÀÊ

iÌiÀ}]Ê

ÕÃiÊ

`i`V>Ìi`Ê

ÌÃ]Ê

iÌV°Ê

ÌÊ

i>V Ê

ÀivÀ}iÀ>ÌÊ

ÌÞ«i°Ê

1`iÀÊ

Ê

VÀVÕÃÌ>ViÃÊ

ÕÃÌÊ

a

gauge

manifold

and

a

charge

hose

in

particular

be

shared

with

other

refrigerant

types

(R22,

R407C,

etc.).

UÊ

1ÃiÊ

>Ê

VÕÌiÀvÜÊ

«ÀiÛiÌÊ

>`>«ÌiÀÊ

ÌÊ

«ÀiÛiÌÊ

Û>VÕÕÊ

«Õ«Ê

Ê

vÀÊ

iÌiÀ}Ê

Ì iÊ

ÀivÀ}iÀ>ÌÊ

ÃÞÃÌi°

UÊ

/ ÃÊÕÌÊVÌ>ÃÊv>VÌÀÞÊV >À}i`ÊÀivÀ}iÀ>ÌÊVÛiÀ

}Ê£xÊvÊÀivÀ}iÀ>ÌÊ««}Ê>`Ê>``Ì>ÊÀivÀ}iÀ>ÌÊV >À}i

ÊÊ

the installation site is not required for an installation with up to 15m refrigerant piping.

When refrigerant piping exceeds 15m, additionally charge an amount calculated from the pipe length and the above table for the portion in excess of 15m.

UÊ

vÊ>ÊiÝÃÌ}Ê««iÊÃÞÃÌiÊÃÊÕÃi`]ÊÀiµÕÀi`ÊÀivÀ}iÀ>ÌÊV >À}i

ÊÛÕiÊÜÊÛ>ÀÞÊ`i«i`}ÊÊÌ iʵÕ`Ê««iÊÃâi°ÊÀÊ

vÕÀÌ iÀÊvÀ>Ì]ÊÃiiʺx°Ê1/</" Ê"Ê8-/ Ê** °»

* When an additional charge volume calculation result is negative, it is not necessary to charge refrigerant additionally.

UÊ

ÀÊ>ÊÃÌ>>ÌÊi>ÃÕÀ}Ê£xÊÀÊÃ ÀÌiÀÊÊ««iÊi}Ì ]ÊV

>À}iÊÌ iÊÀivÀ}iÀ>ÌÊÛÕiÊV >À}i`ÊvÀÊÃ «iÌÊ>ÌÊ

the factory, when you recharge refrigerant after servicing etc.

Fix both liquid and gas service valves at the valve main bodies as illustrated on the right, and then fasten them, applying appropriate fastening torque.

Select

pipes

having

a

wall

thickness

larger

than

the

specified

minimum

pipe

thickness.

14

-

18

49

-

61

68

-

82

45

-

60

30

-

45

15

-

20

150

250

300

1

2

Run the vacuum pump for at least one hour after the vacuum gauge shows –0.1MPa or lower. (–76cmHg or lower)

When

the

system

has

remaining

moisture

inside

or

a

leaky

point,

the

vacuum

gauge

indicator

will

rise.

Check

the

system

for

a

leaky

point

and

then

draw

air

to

create

a

vacuum

again.

Confirm that the vacuum gauge indicator does not rise even if the system is left for one hour or more.

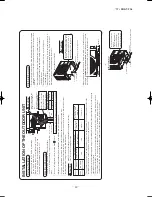

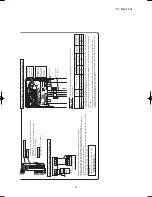

(Gas side)

Charge hose (Designed specifically for R410A)

Compound pressure gauge

Pressure gauge

Gauge manifold (Designed specifically for R410A)

Handle Hi

Vacuum pump

Vacuum pump adapter (Anti-reverse flow type) (Designed specifically for R410A)

Charge hose (Designed specifically for R410A)

Check joint

-0.1MPa

(-76cmHg)

H

an

dl

e

Lo

Service valve

Service valve

(Liquid side)

Service valve cap

Service valve cap

Service valve cap tightening torque (N·m)

Check joint blind nut tightening torque (N·m)

ø6.35 (1/4")

ø12.7 (1/2")

ø15.88 (5/8")

20

-

30

25

-

35

30

-

40

10

-

12

Service valve size

(mm)

Securely tighten the service valve cap and the check joint blind nut after adjustment.

(1)

Dress refrigerant pipes (both gas and liquid pipes) for heat insulation and prevention of dew condensation.

UÊ

«À«iÀÊ

i>ÌÊ

ÃÕ>ÌÉ>Ì`iÜÊ

`ÀiÃÃ}Ê

V>Ê

ÀiÃÕÌÊ

Ê

>Ê

Ü>ÌiÀÊ

i>Ê

ÀÊ

`À««}Ê

V>ÕÃ}Ê

`>>}iÊ

ÌÊ

ÕÃi `Ê

ivviVÌÃ]Ê

iÌV°

Ó®Ê

1ÃiÊ>Ê i>ÌÊÃÕ>Ì}Ê>ÌiÀ>ÊÌ >ÌÊV>ÊÜÌ ÃÌ>`Ê£Óä

℃

or a higher temperature. Poor heat insulating capacity can cause heat insulation problems or cable

deterioration.

UÊ

Ê

}>ÃÊ

««iÃÊ

ÕÃÌÊ

LiÊ

ÃiVÕÀiÞÊ

i>ÌÊ

ÃÕ>Ìi`Ê

Ê

À`iÀÊ

ÌÊ

«ÀiÛiÌÊ

`>>}iÊ

vÀÊ

`À««}Ê

Ü>ÌiÀÊ

Ì >ÌÊ

ViÃÊ

vÀÊ

Ì iÊ

V`iÃ>ÌÊ

vÀi`Ê

Ê

Ì iÊ

`ÕÀ}Ê

>Ê

V}Ê

operation

or

personal

injury

from

burns

because

their

surface

can

reach

quite

a

high

temperature

due

to

discharged

gas

flowing

inside

during

a

heating

operation.

UÊ

7À>«Ê

`ÀÊ

ÕÌýÊ

v>ÀiÊ

ÌÃÊ

ÜÌ Ê

i>ÌÊ

ÃÕ>Ì}Ê

«>ÀÌÃÊ

««iÊ

VÛiÀ®Ê

vÀÊ

i>ÌÊ

ÃÕ>ÌÊ

LÌ Ê

}>ÃÊ

>`Ê

µÕ`Ê

««iî°

UÊ

ÛiÊ

i>ÌÊ

ÃÕ>ÌÊ

ÌÊ

LÌ Ê

}>ÃÊ

>`Ê

µÕ`Ê

Ã`iÊ

««iðÊ

Õ`iÊ

>Ê

i>ÌÊ

ÃÕ>Ì}Ê

>ÌiÀ>Ê

>`Ê

>Ê

««iÊ

Ì} ÌÞÊ

Ì}iÌ iÀÊ

ÃÊ

Ì >ÌÊ

Ê

}>«ÃÊ

>ÞÊ

LiÊ

ivÌÊ

LiÌÜiiÊ

Ì iÊ

>`Ê

wrap

them

together

with

a

connecting

cable

by

a

dressing

tape.

UÊ

Both

gas

and

liquid

pipes

need

to

be

dressed

with

20mm

or

thicker

heat

insulation

materials

above

the

ceiling

where

relative

humidity

exceeds

70%.

(1)

Calculate a required refrigerant charge volume from the following table.

Formula to calculate the volume of additional refrigerant required

7) Additional refrigerant charge

Additional charge volume (g) = { Main length (m) – Factory charged volume 15 (m) } x 20 (g/m)

Model 63(21)

Additional charge volume (g) = { Main length (m) – Factory charged volume 15 (m) } x 25 (g/m)

Model 71(24), 80(28)

20

25

25

1.55

1.80

1.90

15

15

15

Model 63(21)

Model 71(24)

Model 80(28)

Put down the refrigerant volume calculated from the pipe length onto the caution label attached on the service panel.

UÊ

-ViÊ,{£äÊÀivÀ}iÀ>ÌÊÕÃÌÊLiÊV >À}i`ÊÊÌ iʵÕ`Ê« >Ãi]ÊÞ

ÕÊÃ Õ`ÊV >À}iÊÌÊii«}ÊÌ iÊVÌ>iÀÊ

cylinder upside down or using a refrigerant cylinder equipped with a siphon tube.

UÊ

>À}iÊÀivÀ}iÀ>ÌÊ>Ü>ÞÃÊvÀÊÌ iʵÕ`ÊÃ`iÊÃiÀÛViÊ«ÀÌÊÜ

Ì ÊÌ iÊÃiÀÛViÊÛ>ÛiÊÃ ÕÌ°Ê7 iÊÞÕÊv`ÊÌÊ

difficult to charge a required amount, fully open the outdoor unit valves on both liquid and gas sides and charge refrigerant from the gas (suction) side service port, while running the unit in the cooling mode. In doing so, care must be taken so that refrigerant may be discharged from the cylinder in the liquid phase all the time. When the cylinder valve is throttled down or a dedicated conversion tool to change liquid phase refrigerant into mist is used to protect the compressor, however, adjust charge conditions so that refrigerant will gasify upon entering the unit.

UÊ

ÊV >À}}ÊÀivÀ}iÀ>Ì]Ê>Ü>ÞÃÊV >À}iÊ>ÊV>VÕ>Ìi`ÊÛÕiÊLÞ

ÊÕÃ}Ê>ÊÃV>iÊÌÊi>ÃÕÀiÊÌ iÊV >À}iÊ

volume.

UÊ

7 iÊÀivÀ}iÀ>ÌÊÃÊV >À}i`ÊÜÌ ÊÌ iÊÕÌÊLi}ÊÀÕ]ÊV«iÌiÊ>

ÊV >À}iÊ«iÀ>ÌÊÜÌ ÊÎäÕÌið

Running the unit with an insufficient quantity of refrigerant for a long time can cause a compressor failure.

(2)

Charging refrigerant

NOTE

Additional charge volume (g) per meter of refrigerant piping

(liquid pipe ø6.35)

Refrigerant volume charged for shipment at the factory

(kg)

Installation’s pipe length (m) covered without additional refrigerant charge

The screw of the side cover is tightened securely.

Side

cover

Do not hold the valve cap area with a spanner.

RCR012A200C

4. ELECTRICAL WIRING WORK

For details of electrical cabling, refer to the indoor unit installation manual.

H 05 R N R 4or5 G

1.5

Harmonized cable type 300/500 volts Natural-and/or synth. rubber wire insulation Polychloroprene rubber conductors insulation Stranded core Number of conductors One conductor of the cable is the earth conductor (yellow/green) Section of copper wire (mm

2

)

H05RNR4G1.5 (Example) or 245IEC57

Electrical installation work must be performed by an electrical installation service provider qualified by a power provide

r of the country.

Electrical installation work must be executed according to the technical standards and other regulations applicable to electric

al installations in the country.

UÊ

ÊÌÊÕÃiÊ>ÞÊ«ÜiÀÊV>LiÊ} ÌiÀÊÌ >ÊiÊëiVvi`ÊÊ«>Ài

Ì iÃiÃÊvÀÊi>V ÊÌÞ«iÊLiÜ°

UÊ

LÀ>`i`ÊVÀ`ÊV`iÊ`iÃ}>ÌÊÈäÓ{xÊÊx£®

UÊ

À`>ÀÞÊÌÕ} ÊÀÕLLiÀÊÃ i>Ì i`ÊVÀ`ÊV`iÊ`iÃ}>Ì

ÊÈäÓ{xÊÊxή

UÊ

v>ÌÊÌÜÊÌÃiÊVÀ`ÊV`iÊ`iÃ}>ÌÊÈäÓÓÇÊÊ{£®

Ê

1ÃiÊ«ÞV À«ÀiiÊà i>Ì i`ÊviÝLiÊVÀ`ÊV`iÊ`iÃ}>Ì

ÊÈäÓ{xÊxÇ®ÊvÀÊ«ÜiÀÊ

cables of parts of appliances for outdoor use.

UÊ

ÀÕ`ÊÌ iÊÕÌ°ÊÊÌÊViVÌÊÌ iÊ}ÀÕ`}ÊÜÀiÊÌÊ>Ê}>ÃÊ«

«i]ÊÜ>ÌiÀÊ««i]Ê} Ì}ÊÀ`Ê

or telephone grounding wire.

If improperly grounded, an electric shock or malfunction may result.

UÊ

Ê}ÀÕ`}ÊÜÀiÊÕÃÌÊLiÊViVÌi`ÊLivÀiÊViVÌ}ÊÌ iÊ«Üi

ÀÊV>Li°Ê*ÀÛ`iÊ>Ê

grounding wire longer than the power cable.

UÊ

/ iÊÃÌ>>ÌÊvÊ>Ê«ÕÃiÊÜÌ ÃÌ>`}ÊÌÞ«iÊi>ÀÌ Êi>>}i

ÊLÀi>iÀÊÃÊiViÃÃ>ÀÞ°ÊÊÊÊÊÊÊÊÊÊÊ

A failure to install an earth leakage breaker can result in an accident such as an electric shock or a fire.

UÊ

ÊÌÊÌÕÀÊÊÌ iÊ«ÜiÀÊÕÌÊÌ iÊiiVÌÀV>ÊÜÀÊÃÊV«iÌi

`°

UÊ

ÊÌÊÕÃiÊ>ÊV`iÃÛiÊV>«>VÌÀÊvÀÊ«ÜiÀÊv>VÌÀÊ«ÀÛii

ÌÊÕ`iÀÊ>ÞÊVÀVÕÃÌ>ViðÊ

(It dose not improve power factor, while it can cause an abnormal overheat accident)

UÊ

ÀÊ«ÜiÀÊÃÕÀViÊV>LiÃ]ÊÕÃiÊV`ÕÌð

UÊ

ÊÌÊ>ÞÊiiVÌÀVÊVÌÀÊV>LiÃÊÀiÌiÊVÌÀÊ>`ÊÃ}>

}ÊÜÀiîÊ

and other cables together outside the unit. Laying them together can result in the malfunctioning or a failure of the unit due to electric noises.

UÊ

>ÃÌiÊÌ iÊV>LiÃÊÃÊÌ >ÌÊÌ ÃiÊ>ÞÊÌÊÌÕV ÊÌ iÊ««}]ÊiÌV°

UÊ

7 iÊV>LiÃÊ>ÀiÊViVÌi`]Ê>iÊÃÕÀiÊÌ >ÌÊ>ÊiiVÌÀV>ÊV

«iÌÃÊ

within the electrical component box are free of loose connector coupling or terminal connection and then attach the cover securely. (Improper cover attachment can result in malfunctioning or a failure of the unit, if water penetrates into the box.)

UÊ

iÛiÀÊÕÃiÊ>ÊÃ i`ÊV>Li°

UÊ

-,<,-]Ê8<,-Ê>`Ê-,9,-ÊV«iÃÊÜÌ ÊÌ iÊ,Ê i>`Ê,iëÃiÊ>L}ÊiÛViîÊÃÌ>`>À`Ê-É <-{Çxx°Î°£Ê>`Ê

supports demand response modes 1, 2, and 3 (DRM1, 2, and 3). Since the air-conditioner limits the electric power or energy by receiving the DRED input signal, the sense of cooling operation or heating operation may deteriorate over time. The outdoor unit of this air-conditioner is

CAUTION

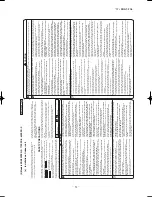

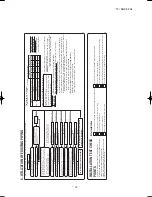

Interconnecting and

grounding wires

(minimum)

Switch breaker

Over current protector

rated capacity

Power source

(minimum)

15A, 30mA, 0.1sec or less

20A, 30mA, 0.1sec or less

30A

30A

16A

20A

2.0mm

2

2.5mm

2

1.5mm

2

Ê8Ê{

1.5mm

2

Ê8Ê{

Earth leakage breaker

Phase

Single-phase

Single-phase

Model 63(21)

Model 71(24), 80(28)

UÊ

/ iÊëiVvV>ÌÃÊà ÜÊÊÌ iÊ>LÛiÊÌ>LiÊ>ÀiÊvÀÊÕÌÃÊÜ

Ì ÕÌÊ i>ÌiÀðÊÀÊÕÌÃÊÜÌ Ê i>ÌiÀÃ]ÊÀiviÀÊÌÊÌ iÊÃÌ>>Ì

Ê

instructions or the construction instructions of the indoor unit.

UÊ

-ÜÌV }i>ÀÊÀÊÀVÕÌÊLÀi>iÀÊV>«>VÌÞÊÜ V ÊÃÊV>VÕ>Ìi

`ÊvÀÊ>ÝÕÊÛiÀÊVÕÀÀiÌÊÃ Õ`ÊLiÊV ÃiÊ>}ÊÌ iÊ

regulations in each country.

UÊ

/ iÊV>LiÊëiVvV>ÌÃÊ>ÀiÊL>Ãi`ÊÊÌ iÊ>ÃÃÕ«ÌÊÌ >ÌÊ>Êi

Ì>ÊÀÊ«>ÃÌVÊV`ÕÌÊÃÊÕÃi`ÊÜÌ ÊÊÀiÊÌ >ÊÌ ÀiiÊV>LiÃÊ

contained in a conduit and a voltage drop is 2%. For an installation falling outside of these conditions, follow the internal cabling regulations. Adapt it to the regulation in effect in each country.

Switchgear or Circuit Breaker

Model SRC-ZR-S

Model SRC-ZRA-S, DXC-ZRA-S, SRC-YRA-S

<T

able of pipe size restrictions>

◎

: Standard pipe size

○

\Ê1Ã>LiÊÊÊ

△

: Restricted to shorter pipe length limits

Additional charge volume (g) = {Main pipe length (m)

-

Length covered without additional

V >À}iÊà ÜÊÊÌ iÊÌ>LiÊ®PÊ8Ê``Ì>ÊV >À}iÊÛÕiÊ

per meter of pipe shown in the table (g/m)

Formula to calculate additional charge volume

NO

Are the existing units our products?

NO

NO

NO

NO

NO

NO

Is the existing pipe system to reuse free of corrosion, flaws or dents?

Repair the damaged parts.

Remove those branches.

Repair the damaged parts.

Check the pipe system for air tightness on the site.

Repair the damaged parts.

No loose pipe supports

NO

9-

ST

AR

T

The existing pipe system is reusable.

The existing pipe system is not reusable. Install a new pipe system.

9-

9-

9-

9-

9-

Are an outdoor unit and an indoor unit connected to the existing pipe system to reuse?

Is the unit to install in the existing pipe system a twin-triple-double-twin model?

Is the existing pipe system to reuse free of gas leaks? (Check whether refrigerant charge was required frequently for the system before)

Are heat insulation materials of the existing pipe system to reuse free of peel-offs or deterioration? (Heat insulation is necessar

y for both gas and liquid pipes)

Change the branching pipe to a specified type.

Does the existing pipe system to reuse satisfy all of the following? (1) The pipe length is 30m or less. (2) The pipe size conforms to the table of pipe size restrictions. (3) The elevation difference between the indoor and outdoor units

conforms to the following restrictions.

Where the outdoor unit is above: 20m or less Where the outdoor unit is below: 20m or less

Which of the following refrigeration oils does the existing unit use? Suniso, MS, Barrel Freeze, HAB, Freol, ether oil, ester oil

Make an inquir

y

for reusability

.

Change

Change is impossible.

>Ê1Ãi

>ÊÌÊ1Ãi

Repair

is impossible.

Air tightness is impossible.

Remove is impossible.

Repair is impossible.

Repair

Repair

Repair

Some loose pipe supports

Air tightness is OK

Remove

Check whether an existing pipe system is reusable or not by using the following flow chart.

Are not there any loose pipe supports?

Are there any branch pipes with no indoor unit connected?

NO

※

If you obtain a negative figure as a result of calculation, no additional refrigerant needs to be charged.

Example)

When an SRC63 is installed in a 10m long existing pipe system (li

quid

ø

9.52,

gas

ø

12.7), the quantity of refrigerant to

charge additionally should be (10m

-

5m) x 60g/m

=

300g.

<Where the existing unit can be run for a cooling operation.>

Carr

y out the following steps with the excising unit

(in the order of (1), (2), (3) and (4))

(1) Run the unit for 30 minutes for a cooling operation. (2) Stop the indoor fan and run the unit for 3 minutes for a cooling operation (returning liquid) (3) Close the liquid side ser

vice valve of the outdoor unit and pump down (refrigerant recover

y)

(4) Blow with nitrogen gas.

※

If discolored refrigeration oil or any foreign matters is discharged by

the blow

, wash the pipe system or install a new pipe system.

UÊÀÊÌ iÊv>ÀiÊÕÌ]Ê`ÊÌÊÕÃiÊÌ iÊ`Êi]ÊLÕÌÊÕÃiÊÌ iÊiÊÃ

Õ««i`ÊÜÌ ÊÌ iÊÕÌ`ÀÊÕÌ°Ê

Process a flare to the dimensions specified for R410A.

<Where the existing unit cannot be run for a cooling operation.>

W

ash the pipe system or install a new pipe system.

UÊvÊÞÕÊV ÃiÊÌÊÜ>à ÊÌ iÊ««iÊÃÞÃÌi]ÊVÌ>VÌÊÕÀÊ`ÃÌÀ

LÕÌÀÊÊÌ iÊ>Ài>°

W

ARNING

※

Check with the flow chart developed for a case where an existing pipe system is reused for a twin-triple-double-twin model published as a technical data sheet.

Always use an earth leakage circuit breaker designed for inverter circuits to prevent a faulty operation.

1ÃiÊV>LiÃÊvÀÊÌiÀViVÌÊÜÀ}ÊÌÊ>Û`ÊÃi}ÊvÊÌ i

Ê

wires. CENELEC code for cables Required field cables.

In case of faulty wiring connection, indoor unit dose not operate. Then, run lamp turns on and timer lamp blinks.

INSTALLATION TEST CHECK POINTS

After installation

Power cables and connecting wires are securely fixed to the terminal block.

The power source voltage is correct as the rating.

The drain hose is fixed securely.

Service valve is fully open.

No gas leaks from the joints of the service valve.

The pipe joints for indoor and outdoor pipes have been insulated.

The reverse flow check cap is attached.

The cover of the pipe cover (A) faces downward to prevent rain from entering.

Gaps are properly sealed between the pipe covers (A) (B) and the wall surface / pipes.

The screw of the side cover is tightened securely.

Check the following points again after completion of the installation, and before turning on the power. Conduct a test run again and ensure that the unit operates properly. Explain to the customer how to use the unit and how to take care of the unit following the instruction manual.

5. UTILIZA

TION OF EXISTING PIPING

Main

fuse

specification

250V 20A

Specification

Part No.

SSA564A136A

Liquid pipe

Gas pipe

1Ã>LÌÞ

Maximum one-way pipe length

Length covered without additional charge

Pipe size

Additional charge volume per meter of pipe

25g/m

ø6.35

ø15.88

◎

30

15

Model 71(24), 80(28)

60g/m

ø9.52

ø15.88

△

12

6

20g/m

ø6.35

ø12.7

◎

30

15

Model 63(21)

60g/m

ø9.52

ø12.7

△

10

5

UÊ

Consult with our distributor in the area, if you need to recover refrigerant and charge it again.

UÊ

ÞÊVL>ÌÃÊvÊ««iÊ

sizes not listed in the table

Model 63(21)

Model 71(24), 80(28)

1ÃiÊ>ÊÌÀµÕiÊÜÀiV °Ê

If a torque wrench is not available, fasten the flare nut manually first and then tighten it further, using the left table as a guide.

Model 71(24), 80(28)

Grommet

Clearance

3. DRAIN PIPING WORK

UÊ

ÝiVÕÌiÊ`À>Ê««}ÊLÞÊÕÃ}Ê>Ê`À>ÊiLÜÊ>`Ê`À>Ê}ÀiÌÃÊ

supplied separately as accessories, where water drained from the outdoor unit is a problem.

UÊ

7>ÌiÀÊ>ÞÊ`À«ÊÜ iÀiÊÌ iÀiÊÃÊ>Ê>À}iÀÊ>ÕÌÊvÊ`À>ÊÜ>Ìi

À°Ê-i>Ê

around the drain elbow and drain grommets with putty or adequate caulking material.

UÊ

`iÃi`ÊÜ>ÌiÀÊ>ÞÊvÜÊÕÌÊvÀÊÛVÌÞÊvÊÃiÀÛViÊÛ>ÛiÊÀÊ

connected pipes.

UÊ

7 iÀiÊÞÕÊ>ÀiÊiÞÊÌÊ >ÛiÊÃiÛiÀ>Ê`>ÞÃÊvÊÃÕLâiÀÊÌi«iÀ>

ÌÕÀiÃÊ

in a row, do not use a drain elbow and drain grommets. (There is a risk of drain water freezing inside and blocking the drain.)

UÊ

7 iÊV`iÃi`ÊÜ>ÌiÀÊii`ÃÊÌÊLiÊi`ÊÌÊ>Ê`À>]ÊiÌV°]Ê

install the unit on a flat base (supplied separately as a locally procured part) or concrete blocks.

Then, secure space for the drain elbow and the drain hose.

Do not put a grommet on this hole. This is a supplementary drain hole to discharge drain water, when a large amount of it is gathered.

Drain elbow

Drain elbow

Grommet

Grommet

Drain hose

(To be procured on the installer’s part)

CAUTION

Wiring diagram

UÊ

ÌÊ `ÃÊV>LiÃÊÊ«>ViÊ>`Ê«ÀÌiVÌÊÌ iÊÌiÀ>ÊViVÌÊ

from external force.

UÊ

/ ÃÊV>«ÊÃÊvÀÊÌ iÊV>LiÊÊÌ iÊÕÌÃ`iÊ`>iÌiÀÊ

9

-

15mm.

Adjust it when it is not suitable.

UÊ

ÌÊ >ÃÊÃÌÕVÊÊÌ iÊ`ÊvÊ>ÊVÌÀÊLÝ°

Cable clamp

Indoor - Outdoor connecting wire

Power cable

DRED cable (Demand response enabling devices)

UÊ>ÀÌ ÊÜÀiÊà >Ê LiÊ9iÜÉÀiiÊ 9É®ÊÊVÀÊ

and longer than other AC wires for safety reason.

Model 63(21)

Power cable, indoor-outdoor connecting wires

UÊ

Always perform grounding system installation work with the power cable unplugged.

UÊ

Connect a pair bearing a common terminal number with an indoor-outdoor connecting wire.

UÊ

In cabling, fasten cables securely with cable clamps so that no external force may work on terminal connections.

UÊ

Grounding terminals are provided in the terminal block.

UÊ

1ÃiÊ*ÞV À«ÀiiÊÃ i>Ì i`ÊviÝLiÊVÀ`ÊV`iÊ`iÃ}>ÌÊÈä

Ó{xÊxÇ]ÊÈäÎÎxÓ{ä®ÊÜÌ Ê

cross-sectional area of 2.0 or 2.5 mm

2

for power cable of outdoor unit.

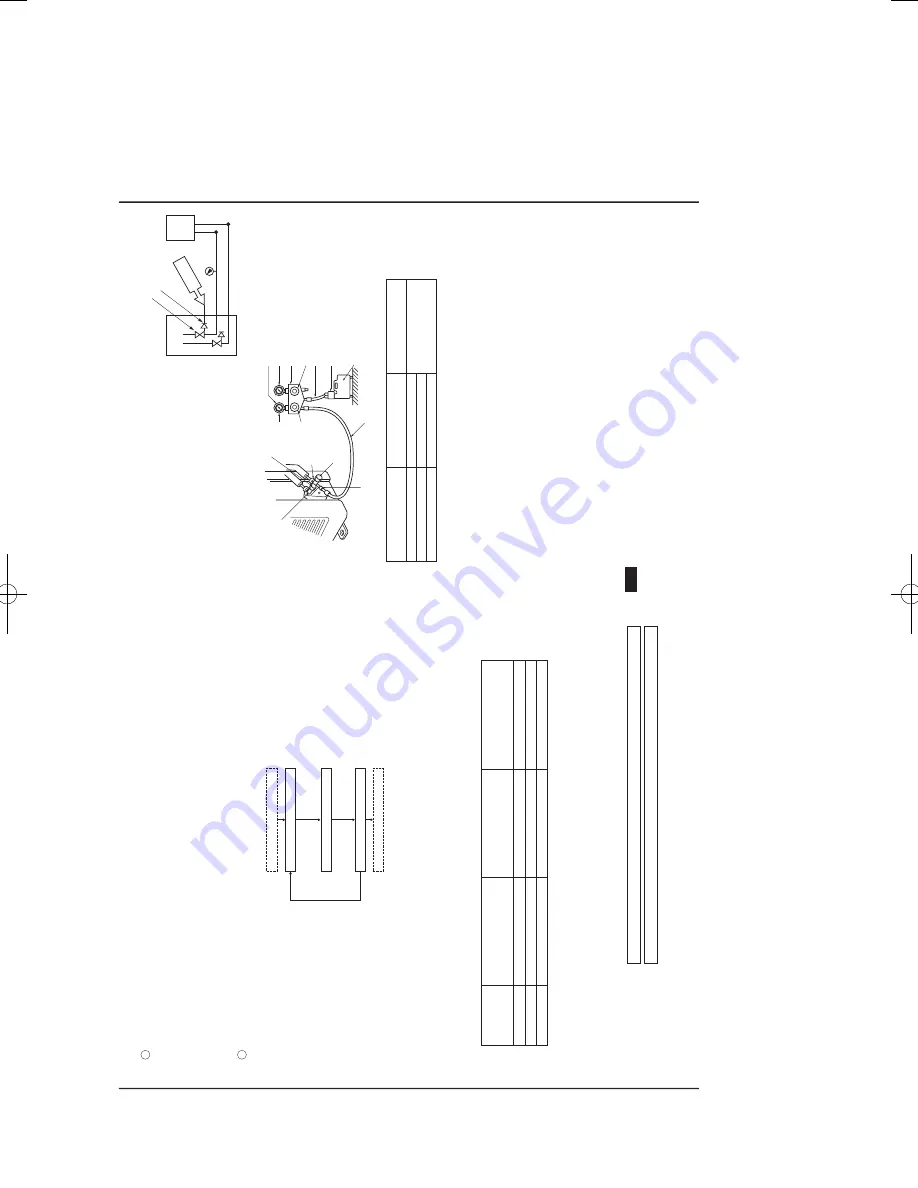

N

L

1

2/N

3

1

2/N

3

Safety breaker

Earth leakage circuit breaker

Earth

Earth

Power

source

Indoor

unit

Outdoor

unit

Model SRC-ZR-S

N

L

D1

C

D1

D2

D3

Safety breaker

Earth leakage circuit breaker

Power

source

DRED*

Outdoor

unit

1

2/N

3

1

2/N

3

Indoor

unit

Model SRC-ZRA-S, DXC-ZRA-S, SRC-YRA-S

C

When

wire

length

exceeds

30m,

use

2.5mm

2

wires.

When

wire

length

exceeds

30m,

use

2.5mm

2

wires.

*Demand response enabling devices

D2

D3

Connecting

cable

between

outdoor

unit

and

DRED

shall

be

double

insulation

layer

,

polychloroprene

sheathed

(>50V)

with

size

4

x

(0.5mm

2

to

2.0mm

2

)

cable

or

flexible

cord,

where

the

maximum

allowable

length

is

30m.

(POWER CABLE) CENELEC code for cables requiring fields cables.

H05RNR3G2.0 [MODEL 63(21)] H05RNR3G2.5 [MODEL 71(24), 80(28)]

Power source terminal block

Power cable, indoor - outdoor connecting wire circuit diagram

UÊ iÊÃÕÀiÊÌÊ>ÌÌ>V Ê

round crimp-type terminal to each wire.

Model 63

Model 71

Model 80

Model 63

Model 71, 80

17-SRK-T206_001-062.indd 59

2017/01/17 17:53:37