-

97

-

'13 • PAC-DB-194

④

Refrigerant piping

Caution

●

Use the new refrigerant pipe.

When re-using the existing pipe system for R22 or R407C, pay attention to the following

items.

・

Change the flare nuts with the attached ones (JIS category 2), and reprocess the flare

parts.

・

Do not use thin-walled pipes.

●

Use phosphorus deoxidized copper alloy seamless pipe (C1220T specified in JIS

H3300) for refrigeration pipe installation.

In addition, make sure there is no damage both inside and outside of the pipe, and no

harmful substances such as sulfur, oxide, dust or a contaminant stuck on the pipes.

●

Do not use any refrigerant other than R410A.

Using other refrigerant except R410A (R22 etc.) may degrade inside refrigeration oil.

And if air getting into refrigerant circuit, it may cause anomaously high pres and may

result in burst, etc.

●

Store the copper pipes indoors and seal the both end of them until they are brazed in

order to avoid any dust, dirt or water getting into pipe. Otherwise it will cause degrada-

tion of refrigeration oil and compressor breakdown, etc.

●

Use special tools for R410A refrigerant.

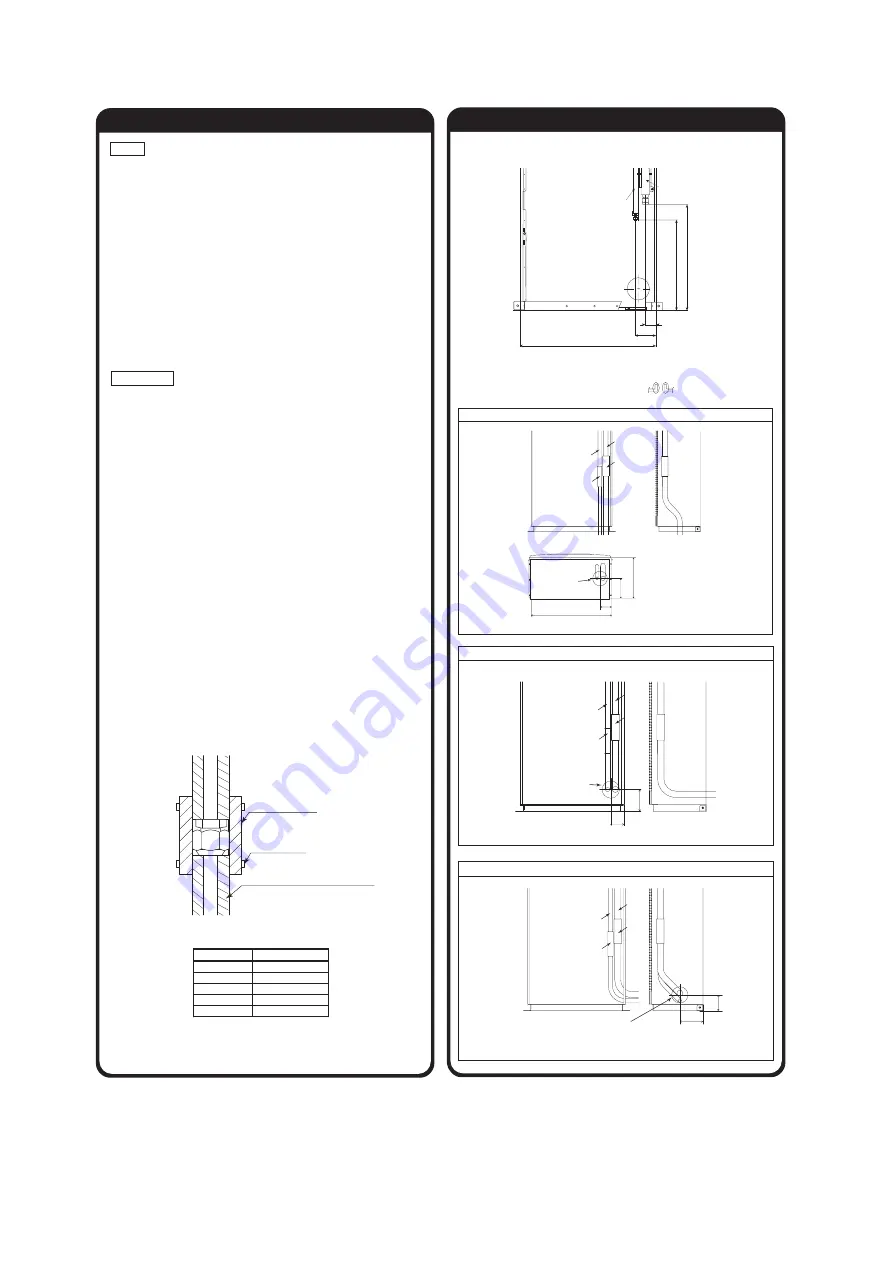

Work procedure

1. Remove the flare nuts and flare caps from the pipes of the indoor unit.

※

Make sure to loosen the flare nut by holding the flared male fitting with a spanner

and giving torque to the nut with another spanner in order to avoid unexpected

stress to the copper pipe, and then remove them.

(Gas may come out a little at this time, but it is no anomaly.)

●

Pay attention that the flare nut may pop out.

(Because it is sometimes pressurized in the indoor unit)

2. Make a flare on liquid pipe and gas pipe, and connect the refrigrant pipes to the indoor

unit.

※

Bend the pipe with as big radius as possible and do not bend the pipe repeatedly. In

addition, do not twist and crush the pipes.

※

Do a flare connection as follows:

●

Make sure to loosen the flare nut by holding the flared male fitting with a spanner

and giving torque to the nut with another spanner in order to avoid unexpected

stress to the copper pipe, and then remove them.

●

When fastening the flare nut, align the refrigeration pipe with the center of flare nut,

screw the nut for 3-4 times by hand and then tighten it with a spanner within the

specified torque mentioned in the table below.

Make sure to hold the flared male fitting on the indoor unit side with another spanner

when tightening the nut in order to avoid unexpected stress on the copper pipe.

3. Cover the flare connection part of the indoor unit with attached insulation material after

a gas leakage inspection, and tighten both ends with attached straps.

●

Make sure to insulate both gas pipes and liquid pipes completely.

※

Incomplete insulation may cause dew condensation and dew dropping.

4. Refrigerant is pre-charged in the outdoor unit.

As for the additional refrigerant charge for the indoor unit and piping, refer to the instal-

lation manual attached to the outdoor unit.

Pipe diameter

Tightening torque N·m

φ

6.35

φ

9.52

φ

12.7

φ

15.88

φ

19.05

14 to 18

34 to 42

49 to 61

68 to 82

100 to 120

Strap (Accessory)

Pipe cover (Accessory)

⑤

Drain pipe

④

Refrigerant piping (Continued)

●

Electric work must be made by qualified electricians according to the “Engineering

standards concerning electric equipment”, “Extension wiring regulations” and the

electric wiring work manual. Be sure to use dedicated electric circuits.

●

Make sure to use specified wires for wiring, and connect them securely. Clamp the

wires to protect the terminal connection from external force.

●

Make sure to protect the unit with the D-type grounding work.

●

For details of wiring work, refer to the attached electric wiring work manual.

⑥

Wire extracting position and wire connecton

⑦

Check list after installation

●

Check the following items after all installation work completed.

Check if;

Expected trouble

Check

The indoor and outdoor units are fixed securely?

Falling, vibration, noise

Inspection for gas leakage is done?

Insufficient capacity

Insulation work is properly done?

Water leakage

Water is drained properly?

Water leakage

Supply voltage is same as mentioned in the model name plate? PCB burnt out, not working at all

There is mis-wiring or mis-connection of piping?

PCB burnt out, not working at all

Earth wiring is connected properly?

Electric shock

Cable size comply with specified size?

PCB burnt out, not working at all

Any obstacle blocks airflow on air inlet and outlet?

Insufficient capacity

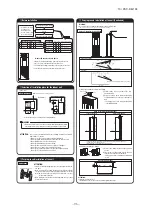

Open the air inlet grill by

holding the grips with

both hands and pulling to

this side.

Control box is located as

illustrated at left. Remove

the cover and make

connections.

PGA012D404

WARNING

CAUTION

Drain socket

Procedure

Backward extraction

85

94

Liquid pipe

Gas pipe

Sideward extraction

94

143

Control box position and power cable connection

Control box

Control box

Clamp (for fixing)

Grounding line

Power cable

Clam (For guide)

Terminal block for signal wire

Terminal block for power cable

Clamp (For fixing)

(Unit front)

(Unit right side)

(Unit front)

(Unit right side)

For side extraction (at right and left)

(ø100 knock-out hole)

For backward extraction

(ø100 knock-out hole)

t%POPUJOTFSUUIFESBJOQJQFEJSFDUMZJOUIFESBJOEJUDIXIFSFUPYJDHBTFTTVDIBT

TVMGGVSJDHBTBSFQSPEVDFE

5PYJDHBTNBZnPXJOUPUIFSPPN

t*OTUBMMUIFESBJOQJQFQSPQFSMZBDDPSEJOHUPUIFJOTUBMMBUJPONBOV"OEJOTVMBUFJUUP

QSFWFOUGSPNEFXDPOEFOTBUJPO

*NQSPQFSJOTUBMMBUJPOPGESBJOQJQFNBZDBVTFEBNBHFPGGVSOJUVSFESBJOBHFXBUFS

MFBLFEPSEFXDPOEFOTBUJPO

Upward bend not allowed

Trap not allowed

Submersion in water not allowed

Decline the pipe lightly.

t*OTVMBUFUIFESBJOQJQFUPQSFWFOUEFXJOH &TQFDJBMMZJOSPPNBOEVOJU

t*ODMJOFUIFESBJOQJQFEPXOXBSEUPUIFPVUMFU o6QXBSECFOEPSUSBQJT

OPUBMMPXFEPOUIFXBZ

t6TFBDPNNFSDJBMIBSEQPMZWJOZMDIMPSJEFQJQF17GPSUIFESBJOQJQF

6TFPGBEIFTJWFBHFOUJTQSPIJCJUFE

ATTENTION:

$POOFDUUIFESBJOTPDLFUUPUIFESBJOQJQF 17QSPWJEFEBUTJUFBOEmYUIFKPJOUXJUI

BEIFTJWFUBQFPSUIFMJLF

8IFOUIFQJQFQSPWJEFEBUTJUFSVOTUISPVHIBSPPNJOTVMBUFUIFQJQFXJUIBDPNNFSDJBM

JOTVMBUPS 1PMZFUIZMFOFGPBN4QFDJmDHSBWJUZUIJDLOFTTNNPSNPSFUPQSFWFOU

EFXJOH

①

3FNPWFUIFDPOUSPMCPYDPWFS mYFEXJUIBTDSFX

②

*OUSPEVDFXJSFTJOUIFVOJUBOEDPOOFDUTFDVSFMZPOUIFUFSNJOBMT

③

'JYFBDIXJSFXJUIBDMBNQ GPSmYJOH

④

*OTUBMMSFNPWFEQBSUTBTUIFZXFSF

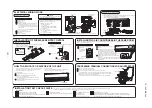

Procedure

t.BLFTVSFUPQBTTUIFQPXFSDBCMFUISPVHIUIFDMBNQ GPSHVJEF

◆

Pipe and wire extracting position

400

48

93

600

468

Liquid pipe

Gas pipe

Downward extraction

440

Liquid pipe

Gas pipe

61

143

305

Pipe cover

(For liquid pipe)

(Unit front)

(Unit bottom)

(Unit right side)

Pipe cover

(For gas pipe)

For downward

extraction

(ø100 hole)

The thickness of insulation should be 20mm or more.

ATTENTION:

t%POPUDVUPGGUIFnBOHFBUUIFIPMFPOUIF

CBTFQMBUFGPSUIFEPXOXBSEFYUSBDUJPO

Pipe cover

(Liquid pipe)

Pipe cover

(Gas pipe)

Liquid pipe

Gas pipe

Pipe cover

(For liquid pipe)

Pipe cover

(For gas pipe)