-

39

-

'13 • PAC-DB-194

[ ]

FS

FM

I

2

SW2

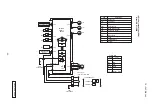

Connector

CNB

~

Z

Drain motor

DM

TB1

SW6

Operation check, Drain motor test run

SW7-1

Fuse

F1,4

Th

I

-R1,2,3

Th

I

-A

Thc

LED

・

3

LED

・

2

TB2

Float switch

Indication lamp

(

Green-Normal operation

)

Indication lamp

(

Red-Inspection

)

Remote control communication address

Model capacity setting

Terminal block

(

Power source

)(□

mark

)

Terminal block

(

Signal line

)(□

mark

)

Thermistor

(

Remote control

)

Thermistor

(

Return air

)

Thermistor

(

Heat exchanger

)

SW5

Plural units Master

/

Slave setting

Fan motor

Color

Mark

BK

Color Marks

Black

BL

Blue

Color

Mark

RD

Red

WH

White

YE

Yellow

YE

/

GN Yellow

/

Green

L

Reactor

BL

3

1

WH

CNW3

WH

RD

RD

1

2

CNI

BL

FS

CNZ

For HA

WH

1

2

CNTA

BL

RD

t

°

Control PCB

Power PCB

RD

YE

t

°

YE

BK

t

°

BK

1

2

3

4

5

6

BK

t

°

BK

1

2

XR1

XR2

XR3

XR4

XR5

(

Remote operation

1

2

3

4

5

6

+12

SW2

SW6

SW5

SW7

LED

・

2 LED

・

3

X

Y

1

3

X

Y

t

°

TB2

WH

BK

WH

8

9

10

11

12

8

9

10

11

12

CNW2

WH

CNW1

WH

CNB

WH

CNN

YE

CNH

BK

CNT

BL

1

2

WH

RD

YE

/

GN

F1

(

5A

)

3

5

CNW0

WH

1

TB1

Power circuit

(

Operation

)

(

Heating

)

(

Compressor ON

)

(

Inspection

)

3

Th

C

Earth

Power source line

Signal line

1 2

3

indoor unit and outdoor unit

Connecting line between

WH

WH

WH

WH

Remote control

input:volt-free contact

)

WH

WH

WH

WH

WH

WH

WH

WH

3

4

5

6

7

1

2

5

6

7

2

3

4

1

YE

/

GN

M

FM

I

2

CNWR

WH

L

1 4 5 6 7

RD BK WH

BL

CNM2

BK

1

3

F4

(

2A

)

CNR

WH

1

2

DM

M

RD

WH

+12

YE

(

Remote operation input:

volt-free contact

)

Powerful mode Valid

/

Invalid

SW7-3

Prepare on site

Th

I

-R1

Th

I

-R2

Th

I

-R3

Th

I

-A

Notes1. indicates wiring on site.

Notes

2. See the wiring diagram of outside unit about the line between

inside unit and outside unit.

Notes

3. Use twin core card

(

0.3mm

2

)

at remote control line.

Notes

4. Do not put remote control line alongside power source line.

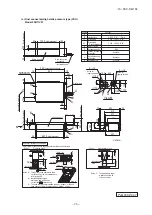

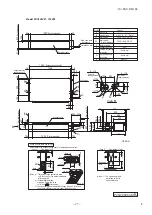

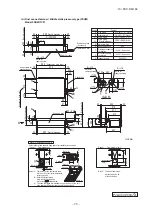

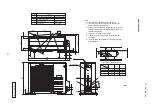

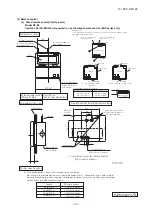

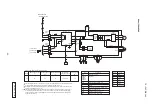

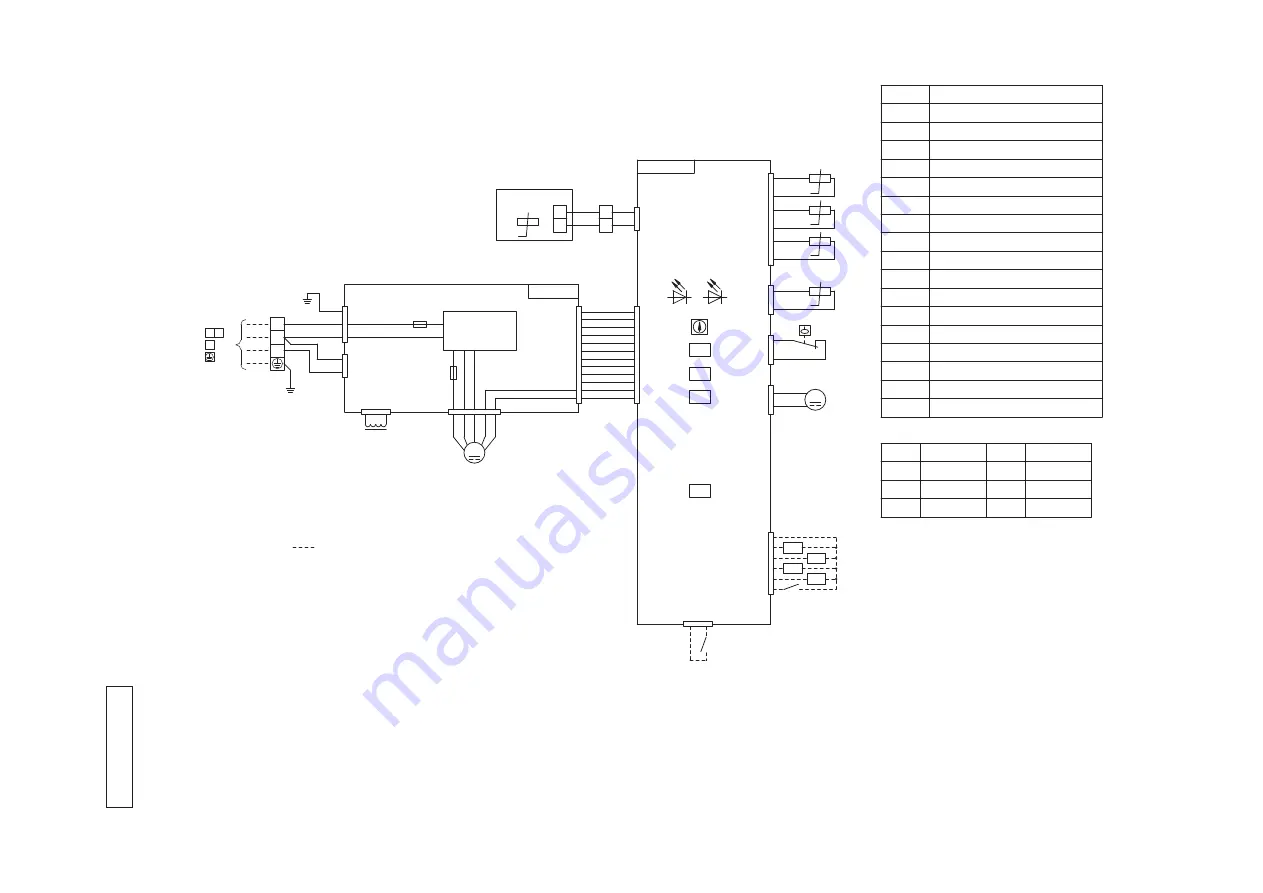

(c) Duct connected-High static pressure type (FDU)

Model FDU71VF1

P

JG

0

0

0

Z

0

4

9