-

101

-

'19 • PAC-SM-332

E36

1. Applicable model

5. Troubleshooting

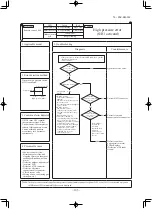

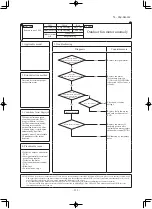

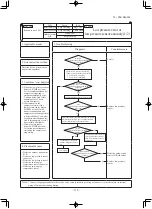

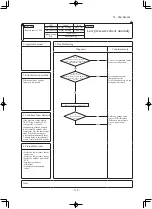

Diagnosis

Countermeasure

* For the contents of control, refer to cooling high pressure protective control

in the protective control by controlling compressor rotation speed of

microcomputer control function for corresponding models.

Are the

characteristics of

discharge pipe temperature

sensor

normal?

Is the

discharge pipe temperature

control normal?

NO

YES

Is the

temperature (measured

actually) at detection of

error correct?

YES

YES

Is the

discharge pipe

temperature error persisted

during cooling / heating

operation?

NO

* For the characteristics of discharge

pipe temperature sensor, refer to E39.

YES

NO

NO

Replace discharge pipe

temperature sensor.

Insufficient refrigerant

amount : Recharge

refrigerant by weighing

proper amount on a scale.

Control operation check *

Defective outdoor

unit control (or main)

PCB

➞

Replace.

Check unit side:

• Isn’t filter clogged?

• Are indoor, outdoor

unit installation spaces

adequate ?

• Isn’t there any short-

circuit of air?

• Isn’t there any fouling,

clogging on indoor heat

exchanger?

2. Error detection method

For the error detection method,

refer to cooling high pressure

protective control in the

protective control by controlling

compressor rotation speed of

microcomputer control function

for corresponding models.

3. Condition of error displayed

When discharge pipe

temperature anomaly is detected

2 times within 60 minutes or

this anomalous state is detected

60 minutes continuously

including compressor stop.

4. Presumable cause

• Defective outdoor unit control

(or main) PCB

• Defective discharge pipe

temperature sensor

• Clogged filter

• Indoor, outdoor unit

installation spaces

• Short-circuit of air on indoor,

outdoor units

• Fouling, clogging of heat

exchanger

Note:

Discharge pipe

temperature error

Error code

Remote control:

LED

Green

Red

Outdoor control PCB

Outdoor inverter

PCB

1-time flash

Keeps flashing

Indoor control PCB

Stays OFF

Keeps flashing

Content

Keeps flashing

Yellow LED