-

6

-

'19 • PAC-SM-332

-

113

-

'16 • PAC-T-251

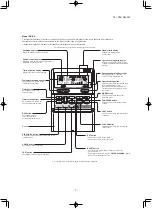

(2) Wireless remote control

Indication section

Operation section

D

C

4

5

6

1

8 9

@

B

A

3

7 2

①

OPERATION MODE display

Indicates selected operation mode.

②

SET TEMP display

Indicates set temperature.

SLEEP TIMER time display

Indicates the amount of time remaining on the sleep timer.

Indoor function setting

number display

Indicates the setting number of the indoor function setting.

③

FAN SPEED display

Indicates the selected air flow volume.

④

UP/DOWN AIR FLOW

display

Indicates the up/down louver position.

⑤

LEFT/RIGHT AIR FLOW

display

Indicates the left/right louver position.

⑥

Clock display

Indicates the current time. If the timer is set, the ON

TIMER and OFF TIMER setting times are indicated.

⑦

ON/OFF TIMER display

Displayed when the timer is set.

⑧

ECO mode display

Displayed when the energy-saving operation is active.

⑨

HI POWER display

Displayed when the high power operation is active.

⑩

NIGHT SETBACK display

Displayed when the home leave mode is active.

⑪

SILENT display

Displayed when the silent mode control is active.

⑫

Motion sensor display

Displayed when the infrared sensor control(motion sensor

control) is enabled.

⑬

Anti draft setting display

Displayed when anti draft setting is enabled.

⑭

Child lock display

Displayed when child lock is enabled.

Transmitter:Sends signal to the air-

conditioner.

①

⑲

⑤

②

⑫

④

③

⑰

⑮

⑨

⑩

⑯

⑪

⑧

⑥

⑭

⑦

⑬

⑱

①

ON/OFF button

When this is pressed once, the air-conditioner starts to

operate and when this is pressed once again, it stops

operating.

②

MODE button

Every time this button is pressed, displays switch as below

(AUTO)

(COOL)

(HEAT)

(FAN)

(DRY)

③

TEMP button

Change the set temperature by pressing or button.

④

FAN SPEED button

The fan speed is switched in the following order: 1-speed

➞

2-speed

➞

3-speed

➞

4-speed

➞

AUTO

➞

1-speed.

⑤

U/D button

Used to determine the up/down louver position.

⑥

ON TIMER button

Used to set the ON TIMER.

⑦

OFF TIMER button

Used to set the OFF TIMER.

⑧

SELECT button

Used to switch the time when setting the timer or adjusting the time.

Used to switch the settings of the indoor function.

⑨

SET button

Used to determine the setting when setting the timer or

adjusting the time.

Used to determine the settings of the indoor function.

When press and hold SET button ,Child Lock is enabled.

⑩

CANCEL button

Used to cancel the timer setting.

⑪

SLEEP button

Used to set the sleep timer.

⑫

ECO button

Pressing this button starts the energy-saving operation.

Pressing this button again cancels it.

⑬

HI POWER button

Pressing this button starts the high power operation.

Pressing this button again cancels it.

⑭

SILENT button

Pressing this button starts the silent mode control.

Pressing this button again cancels it.

⑮

NIGHT SETBACK button

Pressing this button starts the home leave mode.

Pressing this button again cancels it.

⑯

FILTER button

Pressing this button resets FILTER SIGN.

⑰

FUNCTION SETTING switch

Used to set the indoor function.

⑱

TIME SETUP switch

Used to set the current time.

⑲

ACL switch

Used to reset the microcomputer.

(2) Wireless remote control

RCN-E2 ( Except SRK series )

-

113

-

'16 • PAC-T-251

(2) Wireless remote control

Indication section

Operation section