-

87

-

'14 • SR-T-157

'09•SRK-DB-087D

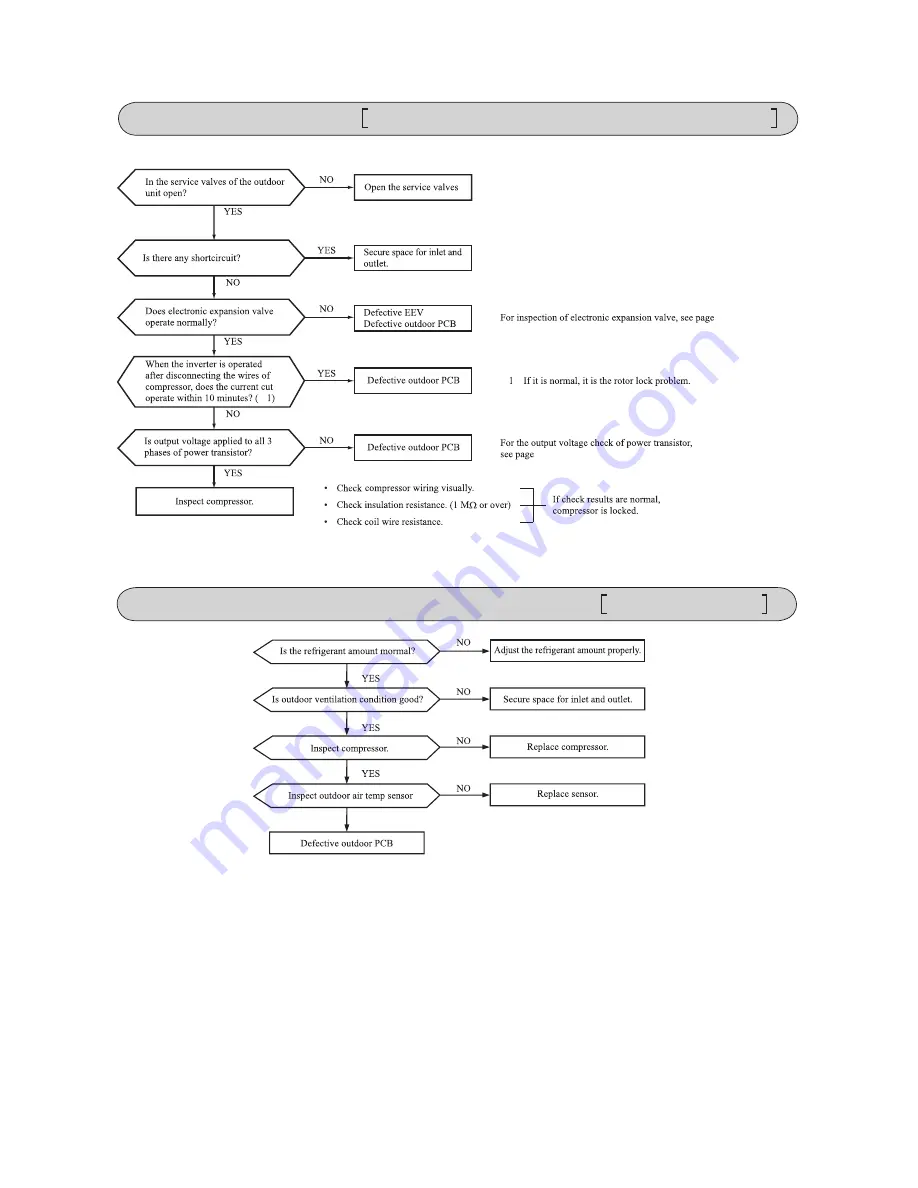

Current cut

Compressor lock, Compressor wiring short circuit, Compressor output is open phase,

Outdoor PCB is faulty, Service valve is closed, EEV is faulty, Compressor faulty.

*

*

Current safe stop

Overload operation, compressor

lock, overcharge

94.

92.

SRC25, 35 : 1.703Ω (U-V, V-W, U-W) or more at 20ºC