-

-

'15 • SR-T-185

Wires for connecting indoor

and outdoor units

Exterior tape

Gas piping

Insulation

Liquid piping

Band (procured locally)

Pipe cover (procured locally)

8) Heating and condensation prevention

Take care so that installed pipes may not touch components within a unit.

If touching with an internal component, it will generate abnormal sounds and/or vibrations.

4) On-site piping work

IMPORTANT

How to remove the side cover

Please remove the screw of a side cover and

remove to the front.

A

B

Flared pipe end : A

(mm)

ø6.35

ø9.52

ø12.7

Copper pipe

outer diameter

0

A –04

9.1

13.2

16.6

ø6.35

ø9.52

ø12.7

Copper pipe

outer diameter

0

~

0.5

1.0

~

1.5

Copper pipe protrusion for flaring : B

(mm)

In the case of a rigid (clutch) type

With an R410A tool With a conventional tool

CAUTION

Do not apply force beyond proper fastening torque in tightening the flare nut.

Tightening angle ( )

Tightening torque (N·m)

ø6.35 (1/4")

ø9.52 (3/8")

ø12.7 (1/2")

Recommended length of a tool handle (mm)

Service valve size (mm)

5) Air tightness test

Gas side

service valve

Check joint

Pre

ssu

rize

Cl

os

e

Outdoor unit

Indoor unit

<Work flow>

6) Evacuation

Pay attention to the following points in addition to the above for the R410A and compatible machines.

Air tightness test completed

Fill refrigerant

Vacuum gauge check

Vacuuming completed

Vacuuming begins

Do not hold the valve cap area with a spanner.

3) Refrigerant pipe wall thickness and material

NOTE

*Phosphorus deoxidized seamless copper pipe ICS 23.040.15, ICS 77.150.30

ø6.35

0.8

O-type pipe

ø9.52

0.8

O-type pipe

ø12.7

0.8

O-type pipe

Pipe diameter [mm]

Minimum pipe wall thickness [mm]

Pipe material*

• Select refrigerant pipes of the table shown on the right wall thickness and material as specified

for each pipe size.

Although outdoor and indoor units themselves have been tested for air tightness at the factory, check the connecting pipes after the installation work for air tightness from the service valve’s

check joint equipped on the outdoor unit side. While conducting a test, keep the service valve shut all the time.

a) Raise the pressure to 0.5MPa, and then stop. Leave it for five minutes to see if the pressure drops.

b) Then raise the pressure to 1.5MPa, and stop. Leave it for five more minutes to see if the pressure drops.

c) Then raise the pressure to the specified level (4.15MPa), and record the ambient temperature and the pressure.

d) If no pressure drop is observed with an installation pressurized to the specified level and left for about one day, it is acceptable. When the ambient temperature fall 1

℃

, the pressure also

fall approximately 0.01MPa. The pressure, if changed, should be compensated for.

e) If a pressure drop is observed in checking e) and a) – d), a leak exists somewhere. Find a leak by applying bubble test liquid to welded parts and flare joints and repair it. After repair,

conduct an air tightness test again.

In conducting an air tightness test, use nitrogen gas and pressurize the system with nitrogen gas from the gas side. Do not use a medium other than nitrogen gas under any circumstances.

• Carry out the on site piping work with the service valve fully closed.

• Give sufficient protection to a pipe end (compressed and blazed, or with an

adhesive tape) so that water or foreign matters may not enter the piping.

• Bend a pipe to a radius as large as practical (R100~R150). Do not bend a pipe

repeatedly to correct its form.

• Flare connection is used between the unit and refrigerant pipe. Flare a pipe after

engaging a flare nut onto it. Flare dimensions for R410A are different from

those for conventional R407C. Although we recommend the use of flaring tools

designed specifically for R410A, conventional flaring tools can also be used by

adjusting the measurement of protrusion B with a protrusion control gauge.

• The pipe should be anchored every 1.5m or less to isolate the vibration.

• Tighten a flare joint securely.

• To prevent a different oil from entering, assign dedicated tools, etc. to each refrigerant type. Under no circumstances must a

gauge manifold and a charge hose in particular be shared with other refrigerant types (R22, R407C, etc.).

• Use a counterflow prevention adapter to prevent vacuum pump oil from entering the refrigerant system.

• This unit contains factory charged refrigerant covering 15m of refrigerant piping and additional refrigerant charge on

the installation site is not required for an installation with up to 15m refrigerant piping.

When refrigerant piping exceeds 15m, additionally charge an amount calculated from the pipe length and the above

table for the portion in excess of 15m.

* When an additional charge volume calculation result is negative, it is not necessary to charge refrigerant additionally.

• For an installation measuring 15m or shorter in pipe length, please charge the refrigerant volume charged for

shipment at the factory, when you recharge refrigerant after servicing etc.

Fix both liquid and gas service valves at the valve main bodies as illustrated on the right, and then fasten them,

applying appropriate fastening torque.

Select pipes having a wall thickness larger than the specified minimum pipe thickness.

14

~

18

34

~

42

49

~

61

45

~

60

30

~

45

30

~

45

150

200

250

Use a torque wrench. If a torque wrench is not

available, fasten the flare nut manually first and then

tighten it further, using the left table as a guide.

1

2

Run the vacuum pump for at least one hour after the vacuum

gauge shows –0.1MPa or lower. (–76cmHg or lower)

When the system has remaining moisture

inside or a leaky point, the vacuum gauge

indicator will rise.

Check the system for a leaky point and

then draw air to create a vacuum again.

Confirm that the vacuum gauge indicator does not rise even if

the system is left for one hour or more.

(Gas side)

Charge hose (Designed specifically for R410A)

Compound pressure gauge

Pressure gauge

Gauge manifold

(Designed specifically for R410A)

Handle Hi

Vacuum pump

Vacuum pump adapter

(Anti-reverse flow type)

(Designed specifically for R410A)

Charge hose

(Designed specifically for R410A)

Check joint

-0.1MPa

(-76cmHg)

Handle Lo

Service valve

Service valve

(Liquid side)

Service valve cap

Service valve cap

Service valve cap

tightening torque (N·m)

Check joint blind nut

tightening torque (N·m)

ø6.35 (1/4")

ø9.52 (3/8")

ø12.7 (1/2")

20

~

30

25

~

35

10

~

12

Service valve size

(mm)

Securely tighten the service valve cap and the check joint blind nut after adjustment.

(1) Dress refrigerant pipes (both gas and liquid pipes) for heat insulation and prevention of dew condensation.

• Improper heat insulation/anti-dew dressing can result in a water leak or dripping causing damage to household effects, etc.

(2) Use a heat insulating material that can withstand 120

℃

or a higher temperature. Poor heat insulating capacity can cause heat insulation problems or cable

deterioration.

• All gas pipes must be securely heat insulated in order to prevent damage from dripping water that comes from the condensation formed on them during a cooling

operation or personal injury from burns because their surface can reach quite a high temperature due to discharged gas flowing inside during a heating operation.

• Wrap indoor units’ flare joints with heat insulating parts (pipe cover) for heat insulation (both gas and liquid pipes).

• Give heat insulation to both gas and liquid side pipes. Bundle a heat insulating material and a pipe tightly together so that no gaps may be left between them and

wrap them together with a connecting cable by a dressing tape.

• Both gas and liquid pipes need to be dressed with 20mm or thicker heat insulation materials above the ceiling where relative humidity exceeds 70%.

(1) Calculate a required refrigerant charge volume from the following table.

Formula to calculate the volume of additional refrigerant required

7) Additional refrigerant charge (Model SRC50/DXC18)

Additional charge volume (kg) = { Main length (m) – Factory charged volume 15 (m) } x 0.02 (kg/m)

0.02

1.35

15

Model SRC50/DXC18

Put down the refrigerant volume calculated from the pipe length onto the caution label attached

on the service panel.

• Since R410A refrigerant must be charged in the liquid phase, you should charge it, keeping the container

cylinder upside down or using a refrigerant cylinder equipped with a siphon tube.

• Charge refrigerant always from the liquid side service port with the service valve shut. When you find it

difficult to charge a required amount, fully open the outdoor unit valves on both liquid and gas sides and

charge refrigerant from the gas (suction) side service port, while running the unit in the cooling mode. In

doing so, care must be taken so that refrigerant may be discharged from the cylinder in the liquid phase

all the time. When the cylinder valve is throttled down or a dedicated conversion tool to change liquid

phase refrigerant into mist is used to protect the compressor, however, adjust charge conditions so that

refrigerant will gasify upon entering the unit.

• In charging refrigerant, always charge a calculated volume by using a scale to measure the charge

volume.

• When refrigerant is charged with the unit being run, complete a charge operation within 30minutes.

Running the unit with an insufficient quantity of refrigerant for a long time can cause a compressor failure.

(2) Charging refrigerant

NOTE

Additional charge volume (kg)

per meter of refrigerant piping

(liquid pipe ø6.35)

Refrigerant volume charged

for shipment at the factory

(kg)

Installation’s pipe length (m)

covered without additional

refrigerant charge

RWC012A044A

4. ELECTRICAL WIRING WORK

For details of electrical cabling, refer to the indoor unit installation manual.

INSTALLATION TEST CHECK POINTS

After installation

Check the following points again after completion of the installation, and before turning on the power. Conduct a test run again and ensure that the unit operates properly.

Explain to the customer how to use the unit and how to take care of the unit following the instruction manual.

Power cables and connecting wires are securely fixed to the terminal block.

The power source voltage is correct as the rating.

The drain hose is fixed securely.

Service valve is fully open.

No gas leaks from the joints of the service valve.

The pipe joints for indoor and outdoor pipes have been insulated.

The reverse flow check cap is attached.

The cover of the pipe cover (A) faces downward to prevent rain from entering.

Gaps are properly sealed between the pipe covers (A) (B) and the wall surface / pipes.

The screw of the side cover is tightened securely.

The screw of the

side cover is

tightened securely.

Side cover

In case of faulty wiring connection, the indoor unit stops,

and then the run lamp turns on and the timer lamp blinks.

Use cables for interconnection wiring to avoid loosening of the wires.

CENELEC code for cables Required field cables.

H

05

R

N

R

4or5

G

1.5

Harmonized cable type

300/500 volts

Natural-and/or synth. rubber wire insulation

Polychloroprene rubber conductors insulation

Stranded core

Number of conductors

One conductor of the cable is the earth conductor

(yellow/green)

Section of copper wire (mm

2

)

H05RNR4G1.5 (Example) or 245IEC57

Electrical installation work must be performed by an electrical installation service provider qualified by a power provider of the country.

Electrical installation work must be executed according to the technical standards and other regulations applicable to electrical installations in the country.

• Do not use any supply cord lighter than one specified in parentheses for each type below.

• braided cord (code designation 60245 IEC 51)

• ordinary tough rubber sheathed cord (code designation 60245 IEC 53)

• flat twin tinsel cord (code designation 60227 IEC 41)

Use polychloroprene sheathed flexible cord (code designation 60245 IEC57) for supply cords of parts of appliances for outdoor use.

• Ground the unit. Do not connect the grounding wire to a gas pipe, water pipe, lightning rod or telephone grounding wire.

If improperly grounded, an electric shock or malfunction may result.

• A grounding wire must be connected before connecting the power cable. Provide a grounding wire longer than the power cable.

• The installation of an impulse withstanding type earth leakage breaker is necessary. A failure to install an earth leakage breaker can result in an accident

such as an electric shock or a fire.

• Do not turn on the power until the electrical work is completed.

• Do not use a condensive capacitor for power factor improvement under any circumstances. (It dose not improve power factor, while it can cause an

abnormal overheat accident)

• For power source cables, use conduits.

• Do not lay electronic control cables (remote control and signaling wires) and other cables together outside the unit. Laying them together can result in

the malfunctioning or a failure of the unit due to electric noises.

• Fasten cables so that may not touch the piping, etc.

• When cables are connected, make sure that all electrical components within the electrical component box are free of loose connector coupling or

terminal connection and then attach the cover securely. (Improper cover attachment can result in malfunctioning or a failure of the unit, if water

penetrates into the box.)

• Never use a shield cable.

• SRC-ZMA-S, SRC-ZMXA-S and DXC-ZMA-S complies with the DRED (Demand Response Enabling Devices) standard AS/NZS4755.3.1 and supports

demand response modes 1, 2, and 3 (DRM1, 2, and 3). Since the air-conditioner limits the electric power or energy by receiving the DRED input signal,

the sense of cooling operation or heating operation may deteriorate over time. The outdoor unit of this air-conditioner is equipped with a terminal block

for DRED input and supports ELV (Extra-Low Voltage) complying with AS/NZS60335.1.

CAUTION

CAUTION

Always use an earth leakage circuit breaker designed for inverter circuits to

prevent a faulty operation.

Interconnecting and

grounding wires

(minimum)

Switch breaker

Over current protector

rated capacity

Power source

(minimum)

15A, 30mA,

0.1sec or less

30A

16A

2.0mm

2

1.5mm

2

X 4

Earth leakage breaker

Phase

Single-phase

• The specifications shown in the above table are for units without heaters. For units with heaters, refer to the

installation instructions or the construction instructions of the indoor unit.

• Switchgear or Circuit breaker capacity which is calculated from MAX. over current should be chosen along the

regulations in each country.

• The cable specifications are based on the assumption that a metal or plastic conduit is used with no more than

three cables contained in a conduit and a voltage drop is 2%. For an installation falling outside of these

conditions, please follow the internal cabling regulations. Adapt it to the regulation in effect in each country.

Switchgear or Circuit Breaker

Power cable, indoor-outdoor connecting wires

• Always perform grounding system installation work with the power cord unplugged.

• Connect a pair bearing a common terminal number with an indoor-outdoor connecting wire.

• In cabling, fasten cables securely with cable clamps so that no external force may work on terminal connections.

• Grounding terminals are provided in the control box.

N L

1 2/N 3

1 2/N 3

Safety

breaker

16A

Earth

leakage

circuit

breaker

Earth

Earth

Power

source

Indoor unit

Outdoor unit

When wire length

exceeds 30m, use

2.5mm

2

wires.

Model SRC-ZM-S

Model SRC-ZMX-S

Model DXC-ZM-S

N L

D1 D2 D3 C

D1 D2 D3

Safety

breaker

16A

Earth

leakage

circuit

breaker

Power

source

DRED*

Outdoor unit

1 2/N 3

1 2/N 3

Indoor unit

When wire length

exceeds 30m, use

2.5mm

2

wires.

Model SRC-ZMA-S

Model SRC-ZMXA-S

Model DXC-ZMA-S

C

Connecting cable between outdoor unit

and DRED shall be double insulation

layer, polychloroprene sheathed (>50V)

with size 4 x (0.5mm

2

to 2.0mm

2

)

cable or flexible cord, where the

maximum allowable length is 30m.

*Demand

response

enabling

devices

Power cable, indoor - outdoor connecting wire circuit diagram

Model SRC20~35ZM-S

Model SRC20~35ZMX-S

Model DXC06ZM-S

Model SRC20~35ZMA-S

Model SRC20~35ZMXA-S

Model DXC09,12ZMA-S

Model SRC50ZM-S

Model SRC50ZMA-S

Model DXC18ZMA-S

Main fuse specification

250V 15A

Specification

Part No.

SSA564A136

Clearance

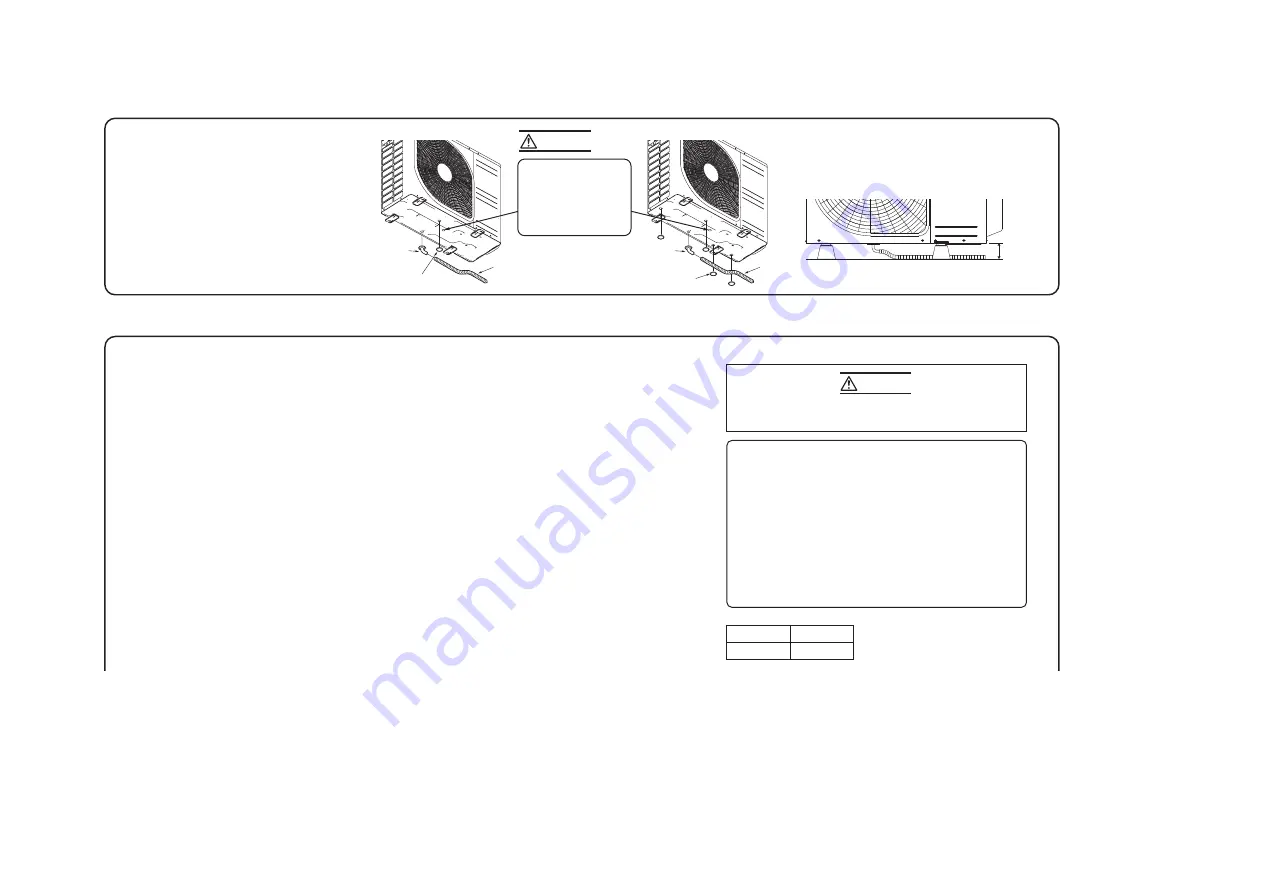

3. DRAIN PIPING WORK

• Execute drain piping by using a drain elbow and drain

grommets supplied separately as accessories, where

water drained from the outdoor unit is a problem.

• Water may drip where there is a larger amount of drain

water. Seal around the drain elbow and drain

grommets with putty or adequate caulking material.

• Condensed water may flow out from vicinity of

operation valve or connected pipes.

• Where you are likely to have several days of sub-zero

temperatures in a row, do not use a drain elbow and

drain grommets. (There is a risk of drain water freezing

inside and blocking the drain.)

• When condensed water needs to be led to a drain, etc., install

the unit on a flat base (supplied separately as an option part)

or concrete blocks.

Then, please secure space for the drain elbow and the drain

hose.

Drain elbow

Grommet

Drain hose

(To be procured on the installer’s part)

Do not put a grommet on

this hole.

This is a supplementary

drain hole to discharge

drain water, when a large

quantity of it is gathered.

Drain elbow

Grommet

Drain hose

(To be procured on the installer’s part)

CAUTION

Model SRC20~35/DXC06~12

Model SRC50/DXC18

Power cable

Indoor - Outdoor

connecting wire

Indoor - Outdoor

connecting wire

DRED cable

(Demand response

enabling devices)

Power cable

Indoor - Outdoor

connecting wire

Indoor - Outdoor

connecting wire

Power cable

DRED cable

(Demand response

enabling devices)

Power cable

• Earth wire shall

be Yellow/Green

(Y/G) in color

and longer than

other AC wires

for safety reason.

• Earth wire shall

be Yellow/Green

(Y/G) in color

and longer than

other AC wires

for safety reason.

Cable name plate

• It holds cables in place and protect the terminal connection

from external force.

• This clamp is for the cable in the outside diameter 9

~

15mm.

Please adjust it when not suitable.

• Please be sure to carry out D-type (type III) grounding work.

• It has stuck on the lid of a control box.

Grounding terminal

Power source terminal block

Cable clamp

Wires for connecting indoor

and outdoor units

Exterior tape

Gas piping

Insulation

Liquid piping

Band (procured locally)

Pipe cover (procured locally)

8) Heating and condensation prevention

Take care so that installed pipes may not touch components within a unit.

If touching with an internal component, it will generate abnormal sounds and/or vibrations.

4) On-site piping work

IMPORTANT

How to remove the side cover

Please remove the screw of a side cover and

remove to the front.

A

B

Flared pipe end : A

(mm)

ø6.35

ø9.52

ø12.7

Copper pipe

outer diameter

0

A –04

9.1

13.2

16.6

ø6.35

ø9.52

ø12.7

Copper pipe

outer diameter

0

~

0.5

1.0

~

1.5

Copper pipe protrusion for flaring : B

(mm)

In the case of a rigid (clutch) type

With an R410A tool With a conventional tool

CAUTION

Do not apply force beyond proper fastening torque in tightening the flare nut.

Tightening angle ( )

Tightening torque (N·m)

ø6.35 (1/4")

ø9.52 (3/8")

ø12.7 (1/2")

Recommended length of a tool handle (mm)

Service valve size (mm)

5) Air tightness test

Gas side

service valve

Check joint

Pre

ssu

rize

Cl

os

e

Outdoor unit

Indoor unit

<Work flow>

6) Evacuation

Pay attention to the following points in addition to the above for the R410A and compatible machines.

Air tightness test completed

Fill refrigerant

Vacuum gauge check

Vacuuming completed

Vacuuming begins

Do not hold the valve cap area with a spanner.

3) Refrigerant pipe wall thickness and material

NOTE

*Phosphorus deoxidized seamless copper pipe ICS 23.040.15, ICS 77.150.30

ø6.35

0.8

O-type pipe

ø9.52

0.8

O-type pipe

ø12.7

0.8

O-type pipe

Pipe diameter [mm]

Minimum pipe wall thickness [mm]

Pipe material*

• Select refrigerant pipes of the table shown on the right wall thickness and material as specified

for each pipe size.

Although outdoor and indoor units themselves have been tested for air tightness at the factory, check the connecting pipes after the installation work for air tightness from the service valve’s

check joint equipped on the outdoor unit side. While conducting a test, keep the service valve shut all the time.

a) Raise the pressure to 0.5MPa, and then stop. Leave it for five minutes to see if the pressure drops.

b) Then raise the pressure to 1.5MPa, and stop. Leave it for five more minutes to see if the pressure drops.

c) Then raise the pressure to the specified level (4.15MPa), and record the ambient temperature and the pressure.

d) If no pressure drop is observed with an installation pressurized to the specified level and left for about one day, it is acceptable. When the ambient temperature fall 1

℃

, the pressure also

fall approximately 0.01MPa. The pressure, if changed, should be compensated for.

e) If a pressure drop is observed in checking e) and a) – d), a leak exists somewhere. Find a leak by applying bubble test liquid to welded parts and flare joints and repair it. After repair,

conduct an air tightness test again.

In conducting an air tightness test, use nitrogen gas and pressurize the system with nitrogen gas from the gas side. Do not use a medium other than nitrogen gas under any circumstances.

• Carry out the on site piping work with the service valve fully closed.

• Give sufficient protection to a pipe end (compressed and blazed, or with an

adhesive tape) so that water or foreign matters may not enter the piping.

• Bend a pipe to a radius as large as practical (R100~R150). Do not bend a pipe

repeatedly to correct its form.

• Flare connection is used between the unit and refrigerant pipe. Flare a pipe after

engaging a flare nut onto it. Flare dimensions for R410A are different from

those for conventional R407C. Although we recommend the use of flaring tools

designed specifically for R410A, conventional flaring tools can also be used by

adjusting the measurement of protrusion B with a protrusion control gauge.

• The pipe should be anchored every 1.5m or less to isolate the vibration.

• Tighten a flare joint securely.

• To prevent a different oil from entering, assign dedicated tools, etc. to each refrigerant type. Under no circumstances must a

gauge manifold and a charge hose in particular be shared with other refrigerant types (R22, R407C, etc.).

• Use a counterflow prevention adapter to prevent vacuum pump oil from entering the refrigerant system.

• This unit contains factory charged refrigerant covering 15m of refrigerant piping and additional refrigerant charge on

the installation site is not required for an installation with up to 15m refrigerant piping.

When refrigerant piping exceeds 15m, additionally charge an amount calculated from the pipe length and the above

table for the portion in excess of 15m.

* When an additional charge volume calculation result is negative, it is not necessary to charge refrigerant additionally.

• For an installation measuring 15m or shorter in pipe length, please charge the refrigerant volume charged for

shipment at the factory, when you recharge refrigerant after servicing etc.

Fix both liquid and gas service valves at the valve main bodies as illustrated on the right, and then fasten them,

applying appropriate fastening torque.

Select pipes having a wall thickness larger than the specified minimum pipe thickness.

14

~

18

34

~

42

49

~

61

45

~

60

30

~

45

30

~

45

150

200

250

Use a torque wrench. If a torque wrench is not

available, fasten the flare nut manually first and then

tighten it further, using the left table as a guide.

1

2

Run the vacuum pump for at least one hour after the vacuum

gauge shows –0.1MPa or lower. (–76cmHg or lower)

When the system has remaining moisture

inside or a leaky point, the vacuum gauge

indicator will rise.

Check the system for a leaky point and

then draw air to create a vacuum again.

Confirm that the vacuum gauge indicator does not rise even if

the system is left for one hour or more.

(Gas side)

Charge hose (Designed specifically for R410A)

Compound pressure gauge

Pressure gauge

Gauge manifold

(Designed specifically for R410A)

Handle Hi

Vacuum pump

Vacuum pump adapter

(Anti-reverse flow type)

(Designed specifically for R410A)

Charge hose

(Designed specifically for R410A)

Check joint

-0.1MPa

(-76cmHg)

Handle Lo

Service valve

Service valve

(Liquid side)

Service valve cap

Service valve cap

Service valve cap

tightening torque (N·m)

Check joint blind nut

tightening torque (N·m)

ø6.35 (1/4")

ø9.52 (3/8")

ø12.7 (1/2")

20

~

30

25

~

35

10

~

12

Service valve size

(mm)

Securely tighten the service valve cap and the check joint blind nut after adjustment.

(1) Dress refrigerant pipes (both gas and liquid pipes) for heat insulation and prevention of dew condensation.

• Improper heat insulation/anti-dew dressing can result in a water leak or dripping causing damage to household effects, etc.

(2) Use a heat insulating material that can withstand 120

℃

or a higher temperature. Poor heat insulating capacity can cause heat insulation problems or cable

deterioration.

• All gas pipes must be securely heat insulated in order to prevent damage from dripping water that comes from the condensation formed on them during a cooling

operation or personal injury from burns because their surface can reach quite a high temperature due to discharged gas flowing inside during a heating operation.

• Wrap indoor units’ flare joints with heat insulating parts (pipe cover) for heat insulation (both gas and liquid pipes).

• Give heat insulation to both gas and liquid side pipes. Bundle a heat insulating material and a pipe tightly together so that no gaps may be left between them and

wrap them together with a connecting cable by a dressing tape.

• Both gas and liquid pipes need to be dressed with 20mm or thicker heat insulation materials above the ceiling where relative humidity exceeds 70%.

(1) Calculate a required refrigerant charge volume from the following table.

Formula to calculate the volume of additional refrigerant required

7) Additional refrigerant charge (Model SRC50/DXC18)

Additional charge volume (kg) = { Main length (m) – Factory charged volume 15 (m) } x 0.02 (kg/m)

0.02

1.35

15

Model SRC50/DXC18

Put down the refrigerant volume calculated from the pipe length onto the caution label attached

on the service panel.

• Since R410A refrigerant must be charged in the liquid phase, you should charge it, keeping the container

cylinder upside down or using a refrigerant cylinder equipped with a siphon tube.

• Charge refrigerant always from the liquid side service port with the service valve shut. When you find it

difficult to charge a required amount, fully open the outdoor unit valves on both liquid and gas sides and

charge refrigerant from the gas (suction) side service port, while running the unit in the cooling mode. In

doing so, care must be taken so that refrigerant may be discharged from the cylinder in the liquid phase

all the time. When the cylinder valve is throttled down or a dedicated conversion tool to change liquid

phase refrigerant into mist is used to protect the compressor, however, adjust charge conditions so that

refrigerant will gasify upon entering the unit.

• In charging refrigerant, always charge a calculated volume by using a scale to measure the charge

volume.

• When refrigerant is charged with the unit being run, complete a charge operation within 30minutes.

Running the unit with an insufficient quantity of refrigerant for a long time can cause a compressor failure.

(2) Charging refrigerant

NOTE

Additional charge volume (kg)

per meter of refrigerant piping

(liquid pipe ø6.35)

Refrigerant volume charged

for shipment at the factory

(kg)

Installation’s pipe length (m)

covered without additional

refrigerant charge

RWC012A044A

4. ELECTRICAL WIRING WORK

For details of electrical cabling, refer to the indoor unit installation manual.

INSTALLATION TEST CHECK POINTS

After installation

Check the following points again after completion of the installation, and before turning on the power. Conduct a test run again and ensure that the unit operates properly.

Explain to the customer how to use the unit and how to take care of the unit following the instruction manual.

Power cables and connecting wires are securely fixed to the terminal block.

The power source voltage is correct as the rating.

The drain hose is fixed securely.

Service valve is fully open.

No gas leaks from the joints of the service valve.

The pipe joints for indoor and outdoor pipes have been insulated.

The reverse flow check cap is attached.

The cover of the pipe cover (A) faces downward to prevent rain from entering.

Gaps are properly sealed between the pipe covers (A) (B) and the wall surface / pipes.

The screw of the side cover is tightened securely.

The screw of the

side cover is

tightened securely.

Side cover

In case of faulty wiring connection, the indoor unit stops,

and then the run lamp turns on and the timer lamp blinks.

Use cables for interconnection wiring to avoid loosening of the wires.

CENELEC code for cables Required field cables.

H

05

R

N

R

4or5

G

1.5

Harmonized cable type

300/500 volts

Natural-and/or synth. rubber wire insulation

Polychloroprene rubber conductors insulation

Stranded core

Number of conductors

One conductor of the cable is the earth conductor

(yellow/green)

Section of copper wire (mm

2

)

H05RNR4G1.5 (Example) or 245IEC57

Electrical installation work must be performed by an electrical installation service provider qualified by a power provider of the country.

Electrical installation work must be executed according to the technical standards and other regulations applicable to electrical installations in the country.

• Do not use any supply cord lighter than one specified in parentheses for each type below.

• braided cord (code designation 60245 IEC 51)

• ordinary tough rubber sheathed cord (code designation 60245 IEC 53)

• flat twin tinsel cord (code designation 60227 IEC 41)

Use polychloroprene sheathed flexible cord (code designation 60245 IEC57) for supply cords of parts of appliances for outdoor use.

• Ground the unit. Do not connect the grounding wire to a gas pipe, water pipe, lightning rod or telephone grounding wire.

If improperly grounded, an electric shock or malfunction may result.

• A grounding wire must be connected before connecting the power cable. Provide a grounding wire longer than the power cable.

• The installation of an impulse withstanding type earth leakage breaker is necessary. A failure to install an earth leakage breaker can result in an accident

such as an electric shock or a fire.

• Do not turn on the power until the electrical work is completed.

• Do not use a condensive capacitor for power factor improvement under any circumstances. (It dose not improve power factor, while it can cause an

abnormal overheat accident)

• For power source cables, use conduits.

• Do not lay electronic control cables (remote control and signaling wires) and other cables together outside the unit. Laying them together can result in

the malfunctioning or a failure of the unit due to electric noises.

• Fasten cables so that may not touch the piping, etc.

• When cables are connected, make sure that all electrical components within the electrical component box are free of loose connector coupling or

terminal connection and then attach the cover securely. (Improper cover attachment can result in malfunctioning or a failure of the unit, if water

penetrates into the box.)

• Never use a shield cable.

• SRC-ZMA-S, SRC-ZMXA-S and DXC-ZMA-S complies with the DRED (Demand Response Enabling Devices) standard AS/NZS4755.3.1 and supports

demand response modes 1, 2, and 3 (DRM1, 2, and 3). Since the air-conditioner limits the electric power or energy by receiving the DRED input signal,

the sense of cooling operation or heating operation may deteriorate over time. The outdoor unit of this air-conditioner is equipped with a terminal block

for DRED input and supports ELV (Extra-Low Voltage) complying with AS/NZS60335.1.

CAUTION

CAUTION

Always use an earth leakage circuit breaker designed for inverter circuits to

prevent a faulty operation.

Interconnecting and

grounding wires

(minimum)

Switch breaker

Over current protector

rated capacity

Power source

(minimum)

15A, 30mA,

0.1sec or less

30A

16A

2.0mm

2

1.5mm

2

X 4

Earth leakage breaker

Phase

Single-phase

• The specifications shown in the above table are for units without heaters. For units with heaters, refer to the

installation instructions or the construction instructions of the indoor unit.

• Switchgear or Circuit breaker capacity which is calculated from MAX. over current should be chosen along the

regulations in each country.

• The cable specifications are based on the assumption that a metal or plastic conduit is used with no more than

three cables contained in a conduit and a voltage drop is 2%. For an installation falling outside of these

conditions, please follow the internal cabling regulations. Adapt it to the regulation in effect in each country.

Switchgear or Circuit Breaker

Power cable, indoor-outdoor connecting wires

• Always perform grounding system installation work with the power cord unplugged.

• Connect a pair bearing a common terminal number with an indoor-outdoor connecting wire.

• In cabling, fasten cables securely with cable clamps so that no external force may work on terminal connections.

• Grounding terminals are provided in the control box.

N L

1 2/N 3

1 2/N 3

Safety

breaker

16A

Earth

leakage

circuit

breaker

Earth

Earth

Power

source

Indoor unit

Outdoor unit

When wire length

exceeds 30m, use

2.5mm

2

wires.

Model SRC-ZM-S

Model SRC-ZMX-S

Model DXC-ZM-S

N L

D1 D2 D3 C

D1 D2 D3

Safety

breaker

16A

Earth

leakage

circuit

breaker

Power

source

DRED*

Outdoor unit

1 2/N 3

1 2/N 3

Indoor unit

When wire length

exceeds 30m, use

2.5mm

2

wires.

Model SRC-ZMA-S

Model SRC-ZMXA-S

Model DXC-ZMA-S

C

Connecting cable between outdoor unit

and DRED shall be double insulation

layer, polychloroprene sheathed (>50V)

with size 4 x (0.5mm

2

to 2.0mm

2

)

cable or flexible cord, where the

maximum allowable length is 30m.

*Demand

response

enabling

devices

Power cable, indoor - outdoor connecting wire circuit diagram

Model SRC20~35ZM-S

Model SRC20~35ZMX-S

Model DXC06ZM-S

Model SRC20~35ZMA-S

Model SRC20~35ZMXA-S

Model DXC09,12ZMA-S

Model SRC50ZM-S

Model SRC50ZMA-S

Model DXC18ZMA-S

Main fuse specification

250V 15A

Specification

Part No.

SSA564A136

Clearance

3. DRAIN PIPING WORK

• Execute drain piping by using a drain elbow and drain

grommets supplied separately as accessories, where

water drained from the outdoor unit is a problem.

• Water may drip where there is a larger amount of drain

water. Seal around the drain elbow and drain

grommets with putty or adequate caulking material.

• Condensed water may flow out from vicinity of

operation valve or connected pipes.

• Where you are likely to have several days of sub-zero

temperatures in a row, do not use a drain elbow and

drain grommets. (There is a risk of drain water freezing

inside and blocking the drain.)

• When condensed water needs to be led to a drain, etc., install

the unit on a flat base (supplied separately as an option part)

or concrete blocks.

Then, please secure space for the drain elbow and the drain

hose.

Drain elbow

Grommet

Drain hose

(To be procured on the installer’s part)

Do not put a grommet on

this hole.

This is a supplementary

drain hole to discharge

drain water, when a large

quantity of it is gathered.

Drain elbow

Grommet

Drain hose

(To be procured on the installer’s part)

CAUTION

Model SRC20~35/DXC06~12

Model SRC50/DXC18

Power cable

Indoor - Outdoor

connecting wire

Indoor - Outdoor

connecting wire

DRED cable

(Demand response

enabling devices)

Power cable

Indoor - Outdoor

connecting wire

Indoor - Outdoor

connecting wire

Power cable

DRED cable

(Demand response

enabling devices)

Power cable

• Earth wire shall

be Yellow/Green

(Y/G) in color

and longer than

other AC wires

for safety reason.

• Earth wire shall

be Yellow/Green

(Y/G) in color

and longer than

other AC wires

for safety reason.

Cable name plate

• It holds cables in place and protect the terminal connection

from external force.

• This clamp is for the cable in the outside diameter 9

~

15mm.

Please adjust it when not suitable.

• Please be sure to carry out D-type (type III) grounding work.

• It has stuck on the lid of a control box.

Grounding terminal

Power source terminal block

Cable clamp