'20 • SR-SM-285

-

105

-

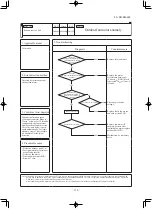

Error code

Remote control:

LED

Green

Red

Indoor

Content

E20

Indoor fan motor rotation

speed anomaly

Keeps flashing 1-time flash

1. Applicable model

5. Troubleshooting

All models

Diagnosis

Countermeasure

NO

YES

YES

Does any

foreign material

intervene in rotational area

of fan propeller?

Is DC280V

detected between

➀

-

➃

of

fan motor connector

CNM?

Is it normalized?

Is the fuse F3 blown?

Does the fan

rotate smoothly when turned

by hand?

YES

NO

NO

NO

YES

(

1

)

Note (1)

➃

for GND

NO

YES

Power source reset

Remove foreign material.

Replace the fan motor.

Check power voltage.

Replace faulty fan motor

and indoor unit control

PCB.

Replace fan motor. (If the

error persists after replacing

the fan motor, replace the

indoor unit control PCB.)

Malfunction by temporary

noise

2. Error detection method

Detected by rotation speed of

indoor fan motor

3. Condition of error displayed

When the actual fan rotation

speed does not reach to the

speed of [required speed

-50 min

-1

] after 2 minutes have

been elapsed since the fan

motor rotation speed command

was output, the unit stops by

detecting indoor fan motor

anomaly.

4. Presumable cause

• Defective indoor unit control

PCB

• Foreign material at rotational

area of fan propeller

• Defective fan motor

• Dust on indoor unit control

PCB

• Blown fuse

• External noise, surge

Note:

Summary of Contents for SRR25ZS-W

Page 79: ... 20 SR SM 285 78 ...