'20 • SR-SM-285

-

52

-

'09•SRK-DB-087D

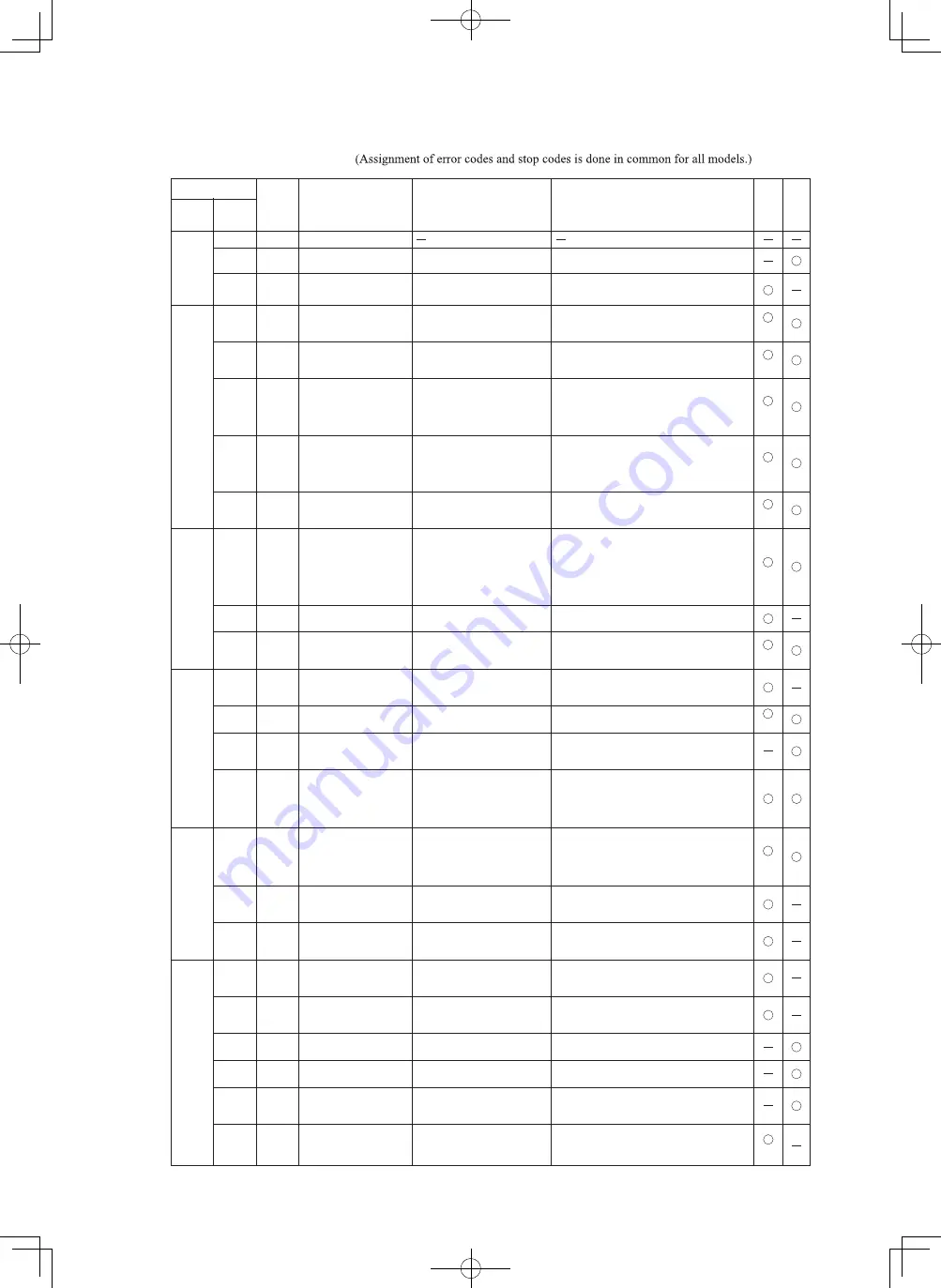

(c) Error code, stop code table

0

Normal

Can not receive signals for 35

Error of wired remote control

wiring

Broken wired remote control wire.

defective indoor PCB

The wired remote control wire Y is open. The wired remote control wires X and Y are reversely connected. Noise is

penetrating the wired remote control lines. The wired remote control or indoor PCB is faulty.

seconds

(if communications have recovered)

Power source is faulty

.

Power source cables and signal lines are improperly wired.

Indoor or outdoor PCB are faulty.

Cooling overload operation.

Outdoor unit fan speed drops.

Outdoor heat exchanger sensor is short circuit.

Refrigerant is insufficient.

Discharge pipe sensor is faulty.

Service valve is closed.

Outdoor air temperature sensor wire is

disconnected.

Connector connections are poor.

Outdoor PCB is faulty.

Discharge pipe sensor wire is

disconnected.

Connector connections are poor.

Outdoor PCB is faulty.

Compressor lock.

Compressor wiring short circuit.

Compressor output is open phase.

Outdoor PCB is faulty.

Service valve is closed.

Electronic expansion valve is faulty.

Compressor is faulty.

Defective active filter.

Outdoor fan motor is faulty.

Connector connections are poor.

Outdoor PCB is faulty.

Outdoor PCB is faulty.

Power transistor is damaged.

Short circuit in the power

transistor (high side)

Current cut circuit breakdown

OFF

05

01

5-time

flash

1-time

flash

Cooling high pressure control

35

5-time

flash

51

1-time

flash

Current cut

42

2-time

flash

Compressor overheat 110°C

36

6-time

flash

Outdoor heat exchanger sensor wire is

disconnected.

Connector connections are poor.

Outdoor PCB is faulty.

Outdoor heat exchanger sensor

is abnormal

37

7-time

flash

Active filter voltage error

47

7-time

flash

Outdoor air temperature sensor

is abnormal

38

8-time

flash

Outdoor unit's fan motor is

abnormal

48

8-time

flash

Discharge pipe sensor is

abnormal (anomalous stop)

39

9-time

flash

(5 times)

(3 times)

(3 times)

(3 times)

Number of flashes when in

service mode

RUN

light

(10's digit)

TIMER

light

(1's digit)

Stop coad

or

Error coad

Error content

Cause

Occurrence conditions

Error

display

Auto

recovery

OFF

3-time

flash

4-time

flash

(2 times)

(2 times)

(3 times)

When it is judged that the power transistor was

damaged at the time the compressor started.

When a fan speed of 75 min

-1

or lower continues for 30

seconds or longer.

When the wrong voltage connected for the power source.

When the outdoor PCB is faulty.

Compressor start fails 42 times in succession and the

reason for the final failure is current cut.

When 35 seconds passes without

communications signals from either the outdoor unit or

the indoor unit being detected correctly.

–55°C or lower is detected for 5 seconds continuously 3 times

within 40 minutes after intial detection of this anomalous

temperature.

Or–55°C higher is detected for 5 seconds continuously

within 20 seconds after power ON.

–55°C or lower is detected for 5 seconds continuously 3 times

within 40 minutes after intial detection of this anomalous

temperature.

Or–55°C higher is detected for 5 seconds continuously

within 20 seconds after power ON.

–25°C or lower is detected for 5 seconds continuously 3 times

within 40 minutes after intial detection of this anomalous

temperature.

When the discharge pipe sensor's value exceeds the set

value.

When the outdoor heat exchanger sensor's value exceeds

the set value.

Service valve is closed.

Refrigerant is insufficient.

Refrigerant is overcharge.

Compressor lock.

Overload operation.

Compressor wiring is disconnected.

Power transistor is damaged.

Power source construction is defective.

Outdoor PCB is faulty.

Compressor is faulty.

Compressor is faulty.

Compressor output is open phase.

Electronic expansion valve is faulty.

Overload operation.

Outdoor PCB is faulty.

Connection lines are faulty.

Indoor or outdoor PCB are faulty.

Indoor or outdoor PCB are faulty.

Noise is causing faulty operation.

Indoor fan motor is faulty.

Connector connections are poor.

Indoor PCB is faulty.

Indoor heat exchanger sensor wire is

disconnected.

Connector connections are poor.

High humidity condition.

Indoor unit fan speed drops.

Indoor heat exchanger sensor is broken wire.

Heating overload operation.

Indoor unit fan speed drops.

Indoor heat exchanger sensor is short circuit.

Anti-condensation prevention control is operating.

Refrigeration cycle system

protective control

Anti-condensation control

Heating high pressure control

Drain trouble

Indoor unit's fan motor is

abnormal

80

OFF

V

Compressor wiring is unconnection

oltage drop

Low speed protective control

59

9-time

flash

Indoor heat exchanger sensor

is abnormal (anomalous stop)

82

2-time

flash

86

87

6-time

flash

7-time

flash

Anti-frost control

85

5-time

flash

57

7-time

flash

84

4-time

flash

Current safe

58

8-time

flash

Connection lines between the

indoor and outdoor units are

faulty

61

1-time

flash

Serial transmission error

62

2-time

flash

Rotor lock

60

OFF

(2 times)

(4 times)

5-time

flash

6-time

flash

8-time

flash

(3 times)

When high pressure control operates during heating

operation and the compressor stops.

When the anti-frost control operates and the compressor

stops during cooling operation.

When 10 seconds passes after the power is turned on

without communications signals from the indoor or

outdoor unit being detected correctly.

When the current is 1A or less at the time the

compressor started.

When the power source voltage drops during operation.

When the compressor command speed is 1ower than 32

rps for 60 minutes.

When a temperature of –28°C or lower is sensed

continuously for 40 minutes during heating operation.

(the compressor stops).

When the indoor unit's fan motor is detected to be running

at 300min

-1

or lower speed with the fan motor

in the ON condition while the air-conditioner is running.

When 7 minute 35 seconds passes without

communications signals from either the outdoor unit or

the indoor unit being detected correctly.

If the float switch OPEN is defected for 3 seconds

continuously or if float switch connector or wire is

disconnected.

After the compressor starts, when the compressor stops

due to rotor lock.

When there is a current safe stop during operation.

When refrigeration cycle system protective control

operates.

Defective drain pump (DM),

broken drain pump wire

Anomalous float switch operation

Defective indoor PCB faulty

Summary of Contents for SRR25ZS-W

Page 79: ... 20 SR SM 285 78 ...