-

1

19

-

'13 • P

A

C-T

-197

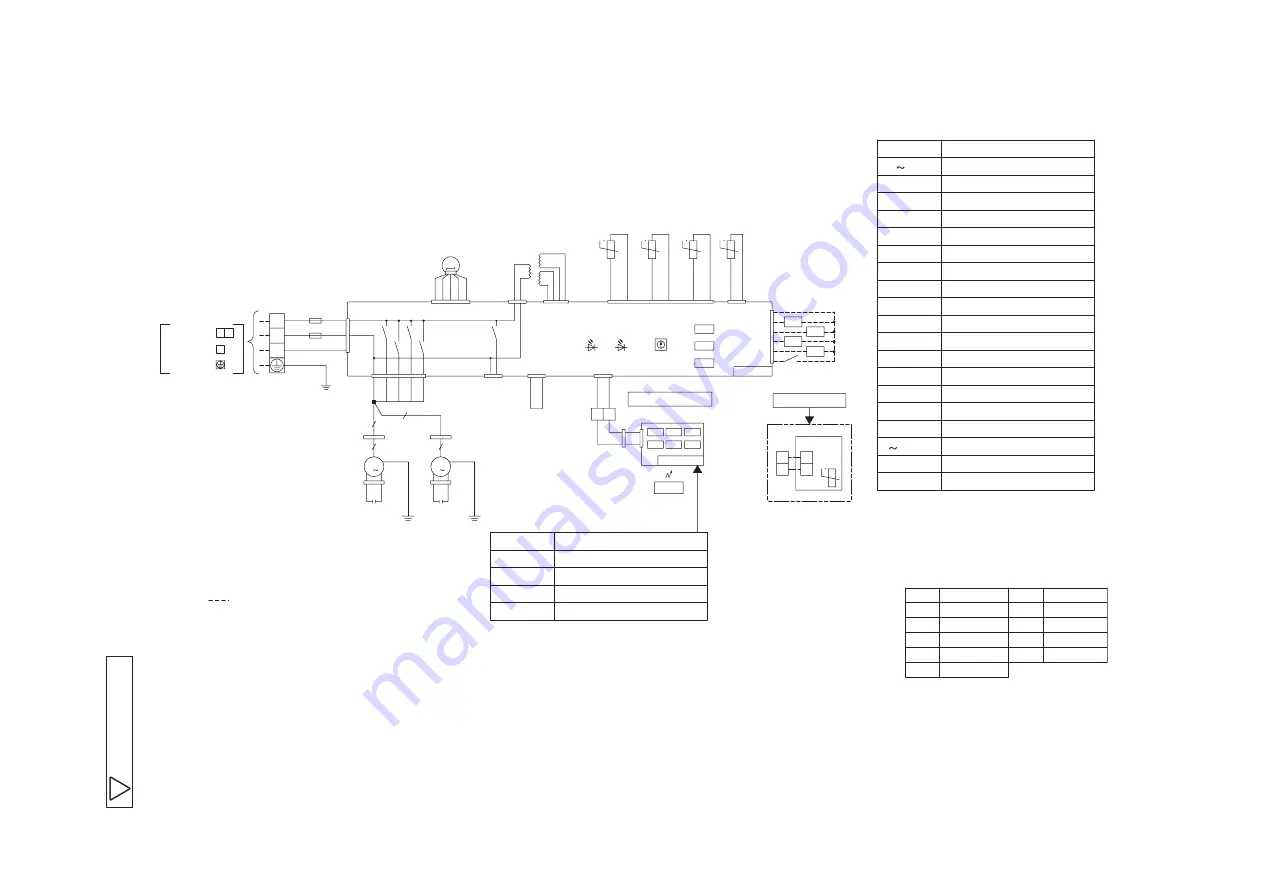

Models FDEN60VF

, 71VF1,

100VF1,

125VF

, 140VF

Capacitor for FMI

CFI 1,2

FMl 1,2

Transformer

Trl

SW2

Connector

CNB

Z

TB1

Relay for FM

X1

3,6

SW5

Operation check, Drain motor test run

SW7-1

Fuse

F

Thl -R1,2,3

Thl -A

Thc

LED

・

3

LED

・

2

Relay for DM

X4

TB2

Fan motor

(

with thermistor

)

Indication lamp

(

Green-Normal operation

)

Indication lamp

(

Red-Inspection

)

Remote control communication address

Plural units Master

/

Slave setting

Terminal block

〔

Power source

)(□

mark

)

Terminal block

〔

Signal line

)(□

mark

)

Thermistor

〔

Remote control

)

Thermistor

〔

Return air

)

Thermistor

〔

Heat exchanger

)

LM

Louver motor

SW6

Model capacity setting

RD

CNW0

BL

WH

RD

X1

3

UH

BR

WH

CNM3

C

WH

1

F

(

3.15A

)

1

3

X6

M

H

BK

BL

5

7

L

RD

9

X3

X2

5

BK

BK

CNB WH

1

3

1

3

TB1

220

ー

240V

LED

・

2

SW2

SW6

SW5

SW7

LED

・

3

F

(

3.15A

)

YE

/

GN

TB2

X Y

WH

BK

Trl

RD RD BR BR

BK

CNW2

19V

24V

1 2 3 4 5

CNJ WH

BL

PK

BR

OR

RD

M

LM

WH

CNF2

WH

CNF1

CNR

3

1

WH

X4

CNI

BL

WH

CNW1

M

1

M

1

XR1

XR2

XR3

XR4

1

2

3

4

5

6

+12

CNT

BL

5

5

5

5

LED4

SW1

LED2 LED3

AMP

SW4

CNB2

WH

CNB

1

2

3

4

CNN YE

5

6

1

2

BK

CNH

Th -R1

Th -A

Th -R2

t

t

Th -R3

t

t

I

I

I

I

BK

BK

BK

BK

WH

RD

Receiver PCB

Remote

control

BK

BK

BK

BK

XR5

(

Remote operation input :

(

Operation

)

(

Heating

)

(

Compressor ON

)

(

Inspection

)

volt-free contact

)

Prepare on site

Closed-end connector

■

mark

Control PCB

Color

Mark

BK

Color Marks

Black

BL

Blue

BR

Brown

Color

Mark

RD

Red

WH

White

YE

/

GN Yellow

/

Green

Receiver PCB

7-segment display

Switches for setting

SW1

LED2

Back-up switch

(

Operation

/

Stop

)

SW4

Indication lamp

(

Green-Normal operation

)

LED3

Indication lamp

(

Yellow-Timer

/

Inspection

)

LED4

PK

Pink

OR

Orange

Remote

Thc

TB2

Wired specification

Wireless specification

X

Y

X

Y

t

control

Earth

Power source line

Signal line

1 2

3

indoor unit and outdoor unit

Connecting line between

2

C

WH

YE

Yellow

CF

FMI 1

I

1

CNFI 1

WH

CFI

FMI 2

2

CNFI 2

WH

Notes 1. indicates wiring on site.

2. See the wiring diagram of outside unit about the line between

indoor unit and outdoor unit.

3. Use twin core cable

(

0.3mm X2

)

at remote control line.

2

YE

/

GN

YE

/

GN

OR

OR

OR

OR

4. Do not put remote control line alongside power source line.

※

When wired remote control are used

only

(

wireless type

)

It is necessary to remove the line that is

connected to the receiver.

Remove signal line connected to the receiver

from primary side of terminal block

(

X,Y

)

.

ATTENTION

Insulate with tape the removed line.

The LED of that removed connector will

not be able to make any indication.

①

②

D

P

F

A

0

0

3

Z

8

2

0

Capacitor for FMI

CFI 1,2

FMl 1,2

Transformer

Trl

SW2

Connector

CNB

Z

TB1

Relay for FM

X1

3,6

SW5

Operation check, Drain motor test run

SW7-1

Fuse

F

Thl -R1,2,3

Thl -A

Thc

LED

・

3

LED

・

2

Relay for DM

X4

TB2

Fan motor

(

with thermistor

)

Indication lamp

(

Green-Normal operation

)

Indication lamp

(

Red-Inspection

)

Remote control communication address

Plural units Master

/

Slave setting

Terminal block

〔

Power source

)(□

mark

)

Terminal block

〔

Signal line

)(□

mark

)

Thermistor

〔

Remote control

)

Thermistor

〔

Return air

)

Thermistor

〔

Heat exchanger

)

LM

Louver motor

SW6

Model capacity setting

RD

CNW0

BL

WH

RD

X1

3

UH

BR

WH

CNM3

C

WH

1

F

(

3.15A

)

1

3

X6

M

H

BK

BL

5

7

L

RD

9

X3

X2

5

BK

BK

CNB WH

1

3

1

3

TB1

220

ー

240V

LED

・

2

SW2

SW6

SW5

SW7

LED

・

3

F

(

3.15A

)

YE

/

GN

TB2

X Y

WH

BK

Trl

RD RD BR BR

BK

CNW2

19V

24V

1 2 3 4 5

CNJ WH

BL

PK

BR

OR

RD

M

LM

WH

CNF2

WH

CNF1

CNR

3

1

WH

X4

CNI

BL

WH

CNW1

M

1

M

1

XR1

XR2

XR3

XR4

1

2

3

4

5

6

+12

CNT

BL

5

5

5

5

LED4

SW1

LED2 LED3

AMP

SW4

CNB2

WH

CNB

1

2

3

4

CNN YE

5

6

1

2

BK

CNH

Th -R1

Th -A

Th -R2

t

t

Th -R3

t

t

I

I

I

I

BK

BK

BK

BK

WH

RD

Receiver PCB

Remote

control

BK

BK

BK

BK

XR5

(

Remote operation input :

(

Operation

)

(

Heating

)

(

Compressor ON

)

(

Inspection

)

volt-free contact

)

Prepare on site

Closed-end connector

■

mark

Control PCB

Color

Mark

BK

Color Marks

Black

BL

Blue

BR

Brown

Color

Mark

RD

Red

WH

White

YE

/

GN Yellow

/

Green

Receiver PCB

7-segment display

Switches for setting

SW1

LED2

Back-up switch

(

Operation

/

Stop

)

SW4

Indication lamp

(

Green-Normal operation

)

LED3

Indication lamp

(

Yellow-Timer

/

Inspection

)

LED4

PK

Pink

OR

Orange

Remote

Thc

TB2

Wired specification

Wireless specification

X

Y

X

Y

t

control

Earth

Power source line

Signal line

1 2

3

indoor unit and outdoor unit

Connecting line between

2

C

WH

YE

Yellow

CF

FMI 1

I

1

CNFI 1

WH

CFI

FMI 2

2

CNFI 2

WH

Notes 1. indicates wiring on site.

2. See the wiring diagram of outside unit about the line between

indoor unit and outdoor unit.

3. Use twin core cable

(

0.3mm X2

)

at remote control line.

2

YE

/

GN

YE

/

GN

OR

OR

OR

OR

4. Do not put remote control line alongside power source line.

※

When wired remote control are used

only

(

wireless type

)

It is necessary to remove the line that is

connected to the receiver.

Remove signal line connected to the receiver

from primary side of terminal block

(

X,Y

)

.

ATTENTION

Insulate with tape the removed line.

The LED of that removed connector will

not be able to make any indication.

①

②

Summary of Contents for V Multi 100VNX

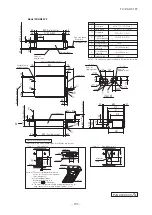

Page 98: ... 97 13 PAC T 197 Models FDT100VF1 125VF 140VF H H H H H C B A F G D G PJF000Z285 A ...

Page 101: ... 100 13 PAC T 197 Models FDEN60VF 71VF1 C2 C1 A B A B D C1 C2 C1 C2 E G F C PFA003Z817 ...

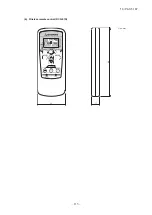

Page 116: ... 115 13 PAC T 197 b Wireless remote control RCN E1R 60 17 150 Unit mm ...

Page 291: ... 290 13 PAC T 197 261 12 PAC T 173 ー K ...

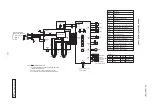

Page 590: ... 589 13 PAC T 197 3 8 SUPER LINK E BOARD SC ADNA E F ...

Page 591: ... 590 13 PAC T 197 ...