-

226

-

'13 • PAC-T-197

-

218

-

'12 • PAC-T-174

Air return grille

Accessories

are inside.

235(Liquid piping)

195(Gas piping)

271

110

76

135

75

10

109

53

53

Unit interior

10 mm slope

Gas

piping

Liquid

piping

Refrigerant line

Drain piping

(right)

Drain piping (left)

Blowout opening

Wall

215

290

690

24

24

B

A

60

100

60

47

120

175

19

27

31

27

108

Right outlet

Top outlet

Rear outlet

Rear cover

Cutout parts

Top cover

Drain line

(left)

Drain line

(rear left)

Grille upside

(Indoor unit)

Filter

Pin

Side panel screw

(1 each on the left and right) (M4)

Side panel

Indoor

unit

Hanging plate

Unscrew

8-12mm

Hanging plate

screw

Hanging

bolts(M8)

Hanging plate

4000~5000mm or more

100mm

or more

300mm or mo

re

150mm or more

5mm or more

Obstacle

Remove the line

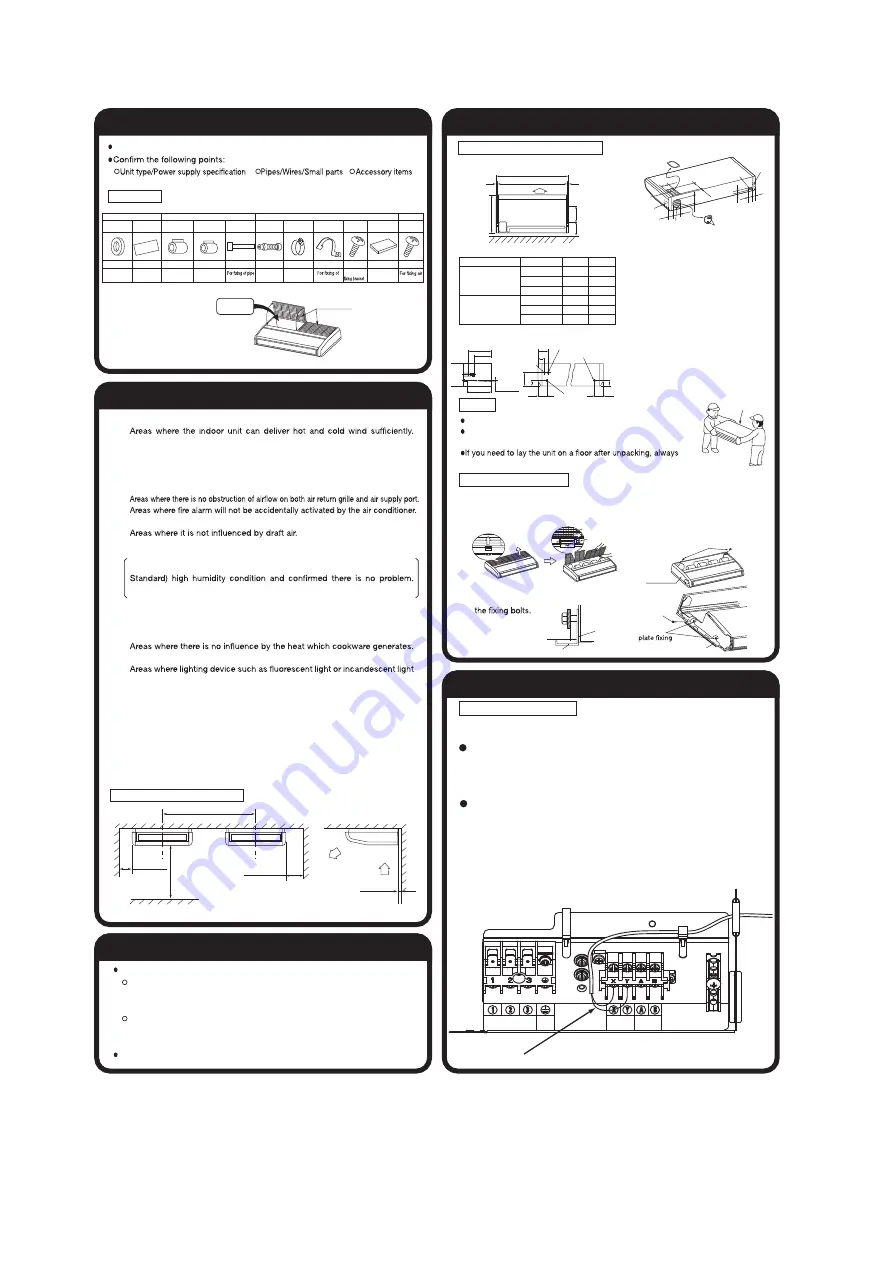

Location of pipe outlets

Pipe position

Pitch of suspension bolts

※

The outlet through which the pipings are taken out is

available in three directions.

※

Pipes can be taken out in 3 directions (rear, right or

top).

・

Cut out holes using nippers, etc.

・

Cut out holes to take out pipes along the cutoff line

on the rear cover.

・

Cut out the top face cover aligning to the piping

position.

・

When taking pipe out to right-hand side, cut out a

hole along the groove at the inside of side panel.

・

After installing pipes and wires, seal clearances

around pipes and wires with putty, etc. to shut off

dust.

Make sure to install the covers at rear and top in order to

protect the inside of unit from intrusion of dust or

protect wires from damages by sharp edges. When

taking them out to the right-hand side, remove burrs or

sharp edges from the cutout.

①

Before installation

③

Preparation before installation (continued)

②

Selection of installation location for the indoor unit

Accessory item

For unit hanging

For refrigerant pipe

Flat washer (M10) Paper pattern Pipe cover (large) Pipe cover (small)

Strap

8

1

1

1

4

For unit hanging

For heat insulation

of gas pipe

For heat insulation

of liquid pipe

cover

For unit hanging

and adjustment

①

Select the suitable areas to install the unit under approval of the user.

・

Suggest to the user to use a circulator if the ceiling height is over 3m to

avoid warm air being accumulated on the ceiling.

・

Areas where there is enough space to install and service.

・

Areas where it can be drained properly. Areas where drain pipe descend-

ing slope can be taken.

・

・

・

Areas where the supply air does not short-circuit.

・

・

Areas not exposed to direct sunlight.

・

Areas where dew point is lower than around 23°C and relative humidity is lower than 80%.

This indoor unit is tested under the condition of JIS (Japan Industrial

However, there is some risk of condensation drop if the air conditioner is

operated under the severer condition than mentioned above.

・

Areas where TV and radio stays away more than 1m. (It could cause jamming and noise.)

・

Areas where any items which will be damaged by getting wet are not placed

such as food, table wares, server, or medical equipment under the unit.

・

・

Areas where not exposed to oil mist, powder and/or steam directly such as above fryer.

・

doesn’t affect the operation.

(A beam from lighting device sometimes affects the infrared receiver for the

wireless remote control and the air conditioner might not work properly.)

②

Check if the place where the air conditioner is installed can hold the weight of the unit.

If it is not able to hold, reinforce the structure with boards and beams strong enough

to hold it. If the strength is not enough, it could cause injury due to unit falling.

③

If there are 2 units of wireless type, keep them away for more than 6m to

avoid malfunction due to cross communication.

④

When plural indoor units are installed nearby, keep them away for more than 4 to 5m.

③

Preparation before installation

Pitch of suspension bolts and pipe position

1. Remove the air return grille.

Slide stoppers (4 places) of the catches,

then pull out the pins ( 4 or 6 places).

3. Remove the hanging plate.

Remove the screw, and then loosen

2. Remove the side panel.

Remove the screw and detach the

side panel by sliding it toward the

direction indicated by the arrow mark.

Move the box as close to the installation area as possible packed.

If it must be unpacked, wrap the unit with a nylon sling,

and be careful not to damage the unit.

put it with the intake grille facing upward.

Series

type

A

B

40 to 50type

1070

1022

60 to 71type

1320

1272

100 to 140type 1620

1572

36 to 56type

1070

1022

71type

1320

1272

112 to 140type

1620

1572

Single Split (PAC)

series

VRF (KX) series

For drain pipe

Drain hose

(with clamp) Hose clamp Fixing bracket

Screw

Heay insulation

1

1

2

1

For drain hose

For drain pipe

connection

drain hose

1

For drain hose

mounting

For installing of

For air return grille

Screw

4

return grille

Preparation before instalation

④

Remote control

Installation of remote control

Up to two receiver or wired remote control can be installed in one indoor unit

group.

Space for installation and service

Haulage

(mm)

Install correctly according to the installation manual.

If suspension bolt becomes longer, do reinforcement of earthquake resistant.

For grid ceiling

When suspension bolt length is over 500mm, or the gap between the ceiling

and roof is over 700mm, apply earthquake resistant brace to the bolt.

In case the unit is hanged directly from the slab and is installed on the

ceiling plane which has enough strength.

When suspension bolt length is over 1000mm, apply the earthquake resistant brace to the bolt.

Prepare four (4) sets of suspension bolt, nut and spring washer (M10) on site.

When both wired and wireless remote control are used

It is necessary to set wired or wireless remote control as slave.

(For the method of changing the setting, refer to the installtion

manual attached to remote control or wireless kit.)

When wired remote control are used only (wireless type)

It is necessary to remove the line that is connected to the receiver.

Remove signal line connected to the receiver from primary side of

terminal block (X, Y).

ATTENTION

①

Insulate with tape the removed line.

②

The LED of that removed connector will not be able to make any

indication.

Summary of Contents for V Multi 100VNX

Page 98: ... 97 13 PAC T 197 Models FDT100VF1 125VF 140VF H H H H H C B A F G D G PJF000Z285 A ...

Page 101: ... 100 13 PAC T 197 Models FDEN60VF 71VF1 C2 C1 A B A B D C1 C2 C1 C2 E G F C PFA003Z817 ...

Page 116: ... 115 13 PAC T 197 b Wireless remote control RCN E1R 60 17 150 Unit mm ...

Page 291: ... 290 13 PAC T 197 261 12 PAC T 173 ー K ...

Page 590: ... 589 13 PAC T 197 3 8 SUPER LINK E BOARD SC ADNA E F ...

Page 591: ... 590 13 PAC T 197 ...