-

302

-

'13 • PAC-T-197

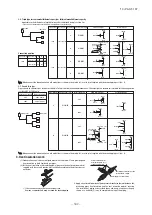

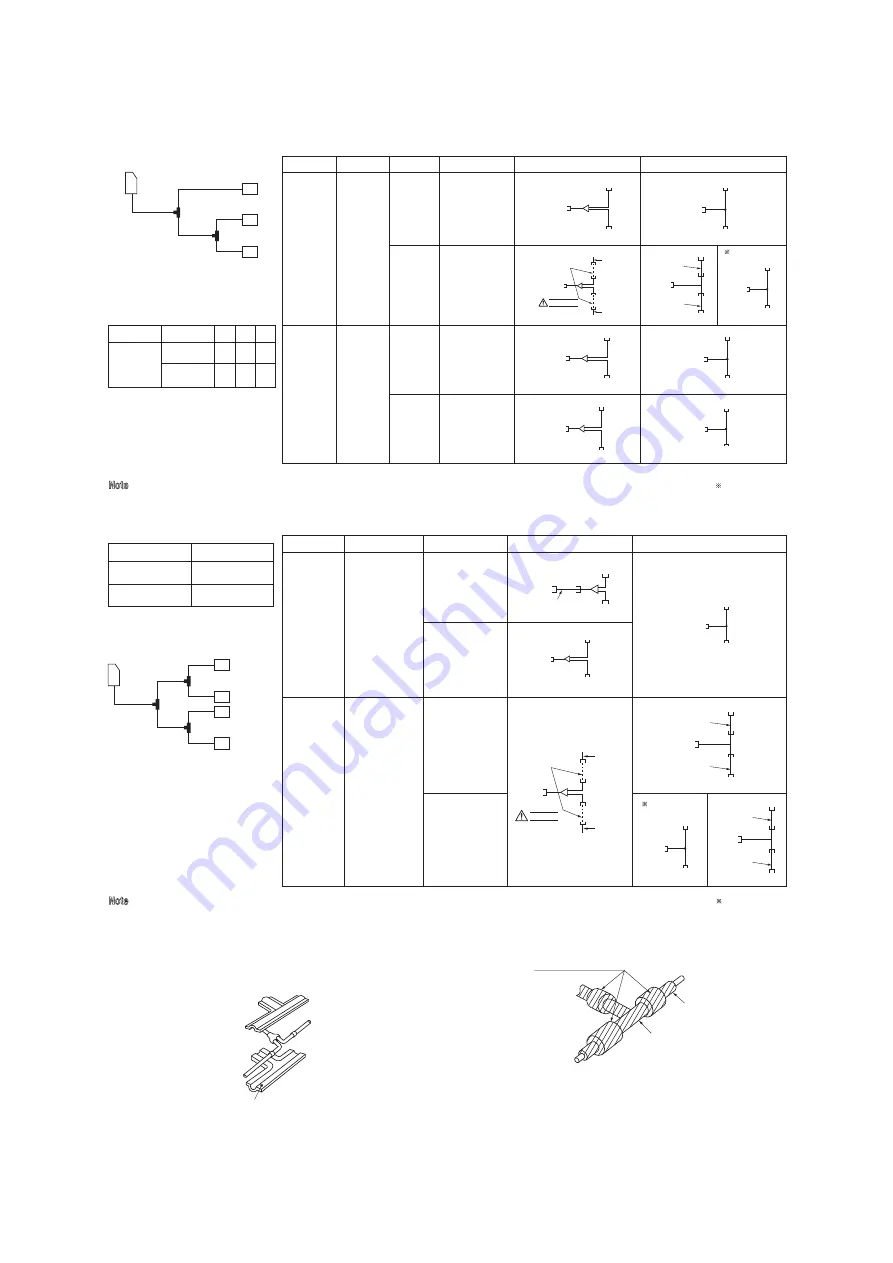

2-7. W-twin type

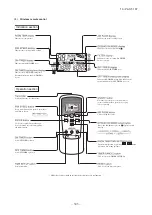

3. Heat insulation work

Heat insulation material

(for pipe insulation, etc.)

to be procured locally

Heat insulation material covering

the installation’s piping

Branching pipe’s heat insulation

Outdoor unit

Indoor unit

a

b

b

Outdoor unit capacity

Indoor unit capacity

8HP

10HP

2HP

×

4 units

2.5HP

×

4 units

(1) Condensation can also occur on liquid pipes with this model. Please provide good

heat insulation to both liquid and gas pipes.

(2) For the heat insulation of a branching pipe, always use the heat insulation material

supplied with the set and provide heat insulation according to the instructions set

out below.

1. It has an adhesive layer on the entire inner face.

Remove a separator and wrap it around the branching pipe.

2. Apply a heat insulation material (to be procured locally) to the joint between the

branching pipe’s heat insulation and the heat insulation material covering

the installation’s piping as described above and wrap a tape over the gap

shown as a hatched (///) area to complete dressing of the piping.

Pipes should be connected as follows for a W-twin installation (4 connected indoor units. The capacity of an outdoor unit available for this configuration

is either 8HP or 10HP only):

Applicable to the difference in length of pipes after the branch being less than 3 m

* Connection is not allowed when the difference in length of pipes is larger than 3 m.

2-6. Triple type for same model/different capacity or different model/different capacity

Outdoor unit

Indoor unit

a

A

B

C

b

2.5HP

+

2.5HP

+

5HP

10HP

Branching pipe Branching pipe set type

Outdoor unit model

Liquid branching pipe

Gas branching pipe

a

b

8HP

10HP

8HP

10HP

DIS-WB1

DIS-WA1

ID12.7

ID9.52

ID9.52

①

②

③

ID25.4

①

②

③

ID15.88

ID15.88

Joint C

ID9.52

ID9.52

ID9.52

①

②

③

Joint B

Joint B

ID15.88

①

②

③

ID12.7

ID12.7

Joint B

Joint B

ID15.88

① ②

③

ID12.7

ID12.7

Joint A

Joint A

ID9.52

①

②

③

Connecting pipe

(

φ

9.52)

Flare joint (

φ

6.35)

Flare joint (

φ

6.35)

CAUTION

Reference

Joint A

Joint A

ID9.52

①

②

③

Connecting pipe

(

φ

9.52)

Flare joint (

φ

6.35)

Flare joint (

φ

6.35)

CAUTION

Reference

Branching pipe

Indoor unit model

Outdoor unit model

Branching pipe set type

Liquid branching pipe

Gas branching pipe

a

b

DIS-WB1

DIS-WA1

ID12.7

ID9.52

ID9.52

①

②

③

ID25.4

①

②

③

ID15.88

ID15.88

ID15.88

①

②

ID15.88

ID15.88

③

3HP

+

3HP

+

4HP

10HP

a

b

DIS-WB1

DIS-WA1

ID12.7

ID9.52

ID9.52

①

②

③

ID9.52

ID9.52

ID9.52

①

②

③

ID25.4

①

②

③

ID15.88

ID15.88

ID15.88

①

②

③

ID15.88

ID15.88

Indoor unit model

Outdoor unit model

A

2.5HP

+

2.5HP

+

5HP

3HP

+

3HP

+

4HP

4HP

5HP

B

3HP

2.5HP

C

3HP

2.5HP

10HP

Connecting position

A

Joint B

Joint B

ID15.88

①

②

③

ID12.7

ID12.7

ID15.88

①

②

ID15.88

ID15.88

③

A

Note When connect the indoor unit of an old model that is shown in the model list, use the joint supplied with the branch piping set like A.

Note When connect the indoor unit of an old model that is shown in the model list, use the joint supplied with the branch piping set like A.

Double Twin type

Double Twin installation (4 connected indoor units. The capacity of an outdoor unit available for this configuration

Summary of Contents for V Multi 100VNX

Page 98: ... 97 13 PAC T 197 Models FDT100VF1 125VF 140VF H H H H H C B A F G D G PJF000Z285 A ...

Page 101: ... 100 13 PAC T 197 Models FDEN60VF 71VF1 C2 C1 A B A B D C1 C2 C1 C2 E G F C PFA003Z817 ...

Page 116: ... 115 13 PAC T 197 b Wireless remote control RCN E1R 60 17 150 Unit mm ...

Page 291: ... 290 13 PAC T 197 261 12 PAC T 173 ー K ...

Page 590: ... 589 13 PAC T 197 3 8 SUPER LINK E BOARD SC ADNA E F ...

Page 591: ... 590 13 PAC T 197 ...