-

361

-

'13 • PAC-T-197

①

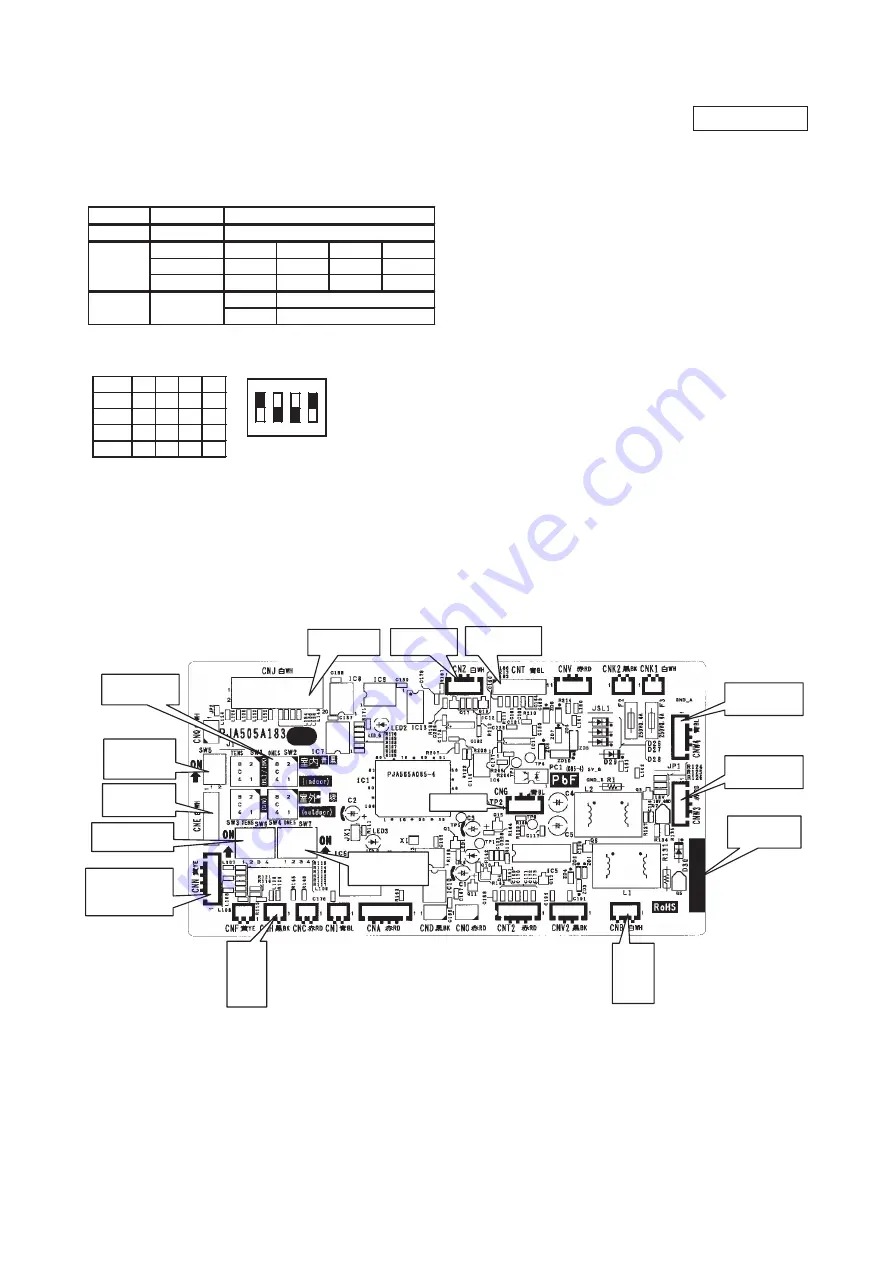

Set to an appropriate address and function using switch on PCB.

Select the same setting with the removed PCB.

②

Set to an appropriate capacity using the model selector switch(SW6).

Select the same capacity with the PCB removed from the unit.

③

Replace the PCB

1. Fix the PCB so as not to pitch the cords.

2. Connect connectors to the PCB. Connect a cable connector with the PCB connector of the same color.

3.Do not pass CPU surrounding about wirings.

④

Control PCB

Parts mounting are different by the kind of PCB.

Part number

SW2 (Blue)

Address setting

SW5

Master/Slave

setting

SW7

Function setting

CNT(Blue)

External switch

CNJ(White)

Louver motor

CNN(Yellow)

Thermistor

(Heat exchanger)

C

N

H

(B

la

c

k)

T

h

e

rm

is

to

r

(R

e

tu

rn

a

ir

)

CNW3(Red)

Power PCB

C

N

B

(W

h

it

e

)

R

e

m

o

te

c

o

n

tr

o

l

CNG(Blue)

CNZ(White)

HA

CNE(White)

RAM checker

CNW4(Blue)

Power PCB

SW6

Capacity setting

item

switch

Address

SW2

Master

Slave1

Slave2

Slave3

SW5-1

-

-

〇

〇

SW5-2

-

〇

-

〇

-

〇

Content of control

Plural indoor units control by1 remote control

Master /Slave

setting

Test run

SW7-1

Normal

Operation check/drain motor test run

SW6

-1

-2

-3

-4

100V

〇

〇

-

〇

125V

-

-

〇

〇

140V

〇

-

〇

〇

71V

〇

-

-

〇

SW6

ON

1

2

3

4

Example setting for 71V

a)

Control PCB

Replace and set up the PCB according to this instruction.

PSB012D976C

4)

Model FDF series

Summary of Contents for V Multi 100VNX

Page 98: ... 97 13 PAC T 197 Models FDT100VF1 125VF 140VF H H H H H C B A F G D G PJF000Z285 A ...

Page 101: ... 100 13 PAC T 197 Models FDEN60VF 71VF1 C2 C1 A B A B D C1 C2 C1 C2 E G F C PFA003Z817 ...

Page 116: ... 115 13 PAC T 197 b Wireless remote control RCN E1R 60 17 150 Unit mm ...

Page 291: ... 290 13 PAC T 197 261 12 PAC T 173 ー K ...

Page 590: ... 589 13 PAC T 197 3 8 SUPER LINK E BOARD SC ADNA E F ...

Page 591: ... 590 13 PAC T 197 ...