-

346

-

'13 • PAC-T-197

(7) Silent mode

(a) As “Silent mode start” signal is received from the remote control, it operates by dropping the outdoor unit fan tap and the

compressor speed (frequency).

(b) For details, refer to items (1) and (4) above.

(8) Test run

(a) It is possible to operate from the outdoor unit using the dip switch on the outdoor unit control PCB.

SW3-3

(SW5-3)

ON

SW3-4

(SW5-4)

OFF

Cooling test run

ON

Heating test run

OFF

Normal and end of test run

Make sure to turn SW3-3 (SW5-3) to OFF after the end of operation.

Note (1) Value in (

) are for the model 71.

(b) Test run control

(i) Operation is performed at the maximum compressor speed (frequency), which is determined for each model.

(ii) Each protective control and error detection control are effective.

(iii) If SW3-4 (SW5-4) is switched during test run, the compressor is stoped for once by the stop control and the cooling/

heating operation is switched.

Note (1) Value in (

) is for the model 71.

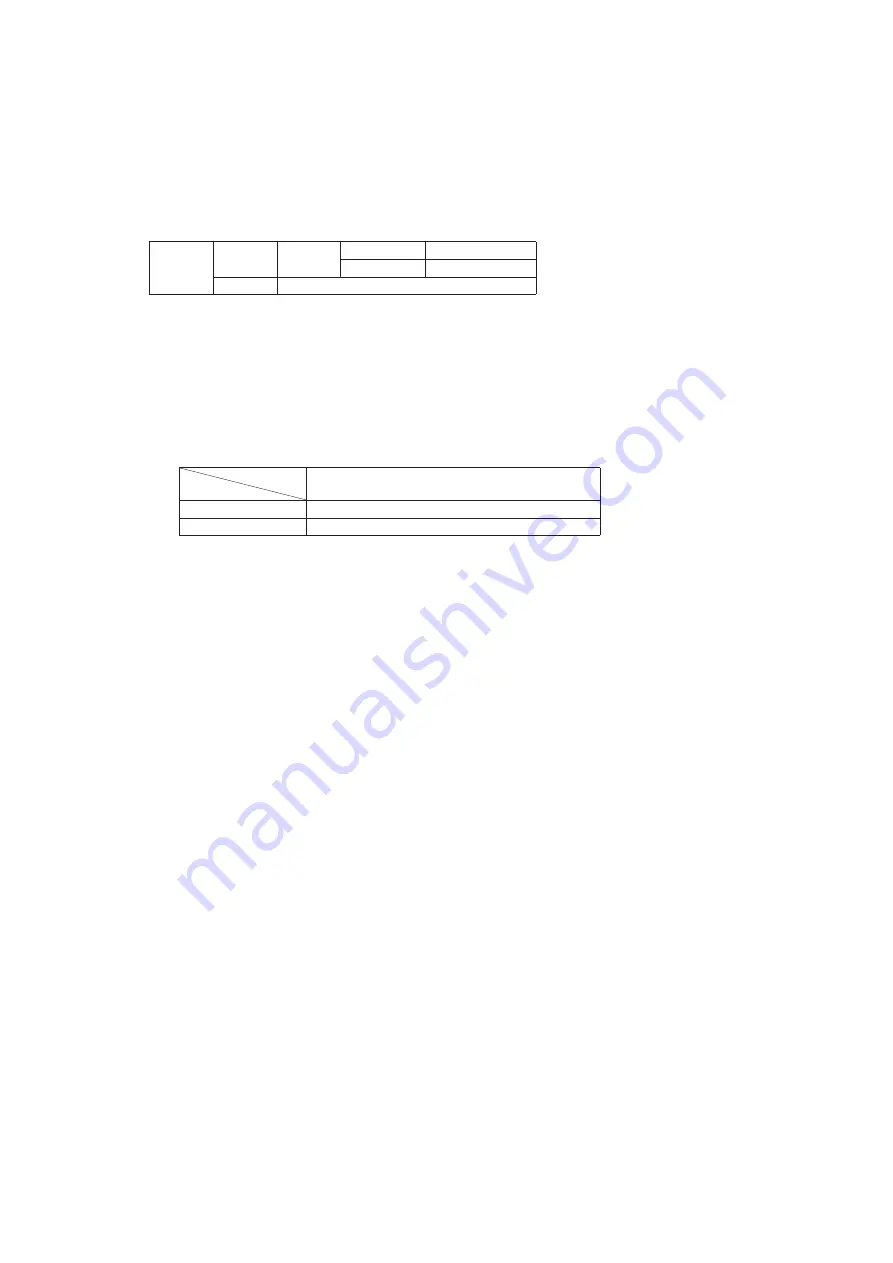

(iv) Setting and display of remote control during test run

Item

Mode

Contents of remote controller setting/display

Cooling test run

Setting temperature of cooling is 5°C.

Heating test run

Setting temperature of heating (preparation) is 30°C.

(9) Pump-down control

Turning ON the pump-down switch SW1 (SW9) for 2 seconds during the operation stop or anomalous stop (excluding the

thermostat OFF), the pump-down operation is performed. (This is invalid when the indoor unit is operating. This is effective

even when the indoor unit is stopped by the anomalous stop or the power supply is turned OFF.)

Note (1) Value in (

) is for the model 71.

(a) Control contents

(i) Close the service valve at the liquid side. (It is left open at the gas side.)

(ii) Compressor is started with the target speed (frequency) at 71:62, 100. 125

・

140:45 rps in the cooling mode.

(iii) Red and green lamps (LED) flash continuously on the outdoor unit control PCB.

(iv) Each of protection and error detection controls, excluding the low pressure control, anti-frost control and dewing

prevention control, is effective.

(v) Outdoor unit fan is controlled as usual.

(vi) Electronic expansion valve is fully opened.

(b) Control ending conditions

Stop control is initiated depending on any of the following conditions.

(i) Low pressure of 0.087MPa or lower is detected for 5 seconds continuously.

1) Red LED: Light, Green LED: Flashing, Remote control: Displays stop.

2) It is possible to restart when the low pressure is 0.087MPa or higher.

3) Electronic expansion valve (cooling/heating) is kept fully open.

(ii) Stop by the error detection control

1) Red LED: Keeps flashing, Green LED: Flashing

2) Restart is prohibited. To return to normal operation, reset the power supply.

3) Electronic expansion valve (cooling/heating) is left fully open.

(iii) When the cumulative operation time of compressor under the pump-down control becomes 5 minutes.

1) Red LED: stays OFF, Green LED: Flashing, Remote control: Stop

2) It is possible to pump-down again.

3) Electronic expansion valve (cooling/heating) is left fully open.

Note (1) After the stop of compressor, close the service valve at the gas side.

Caution: Since pressing the pump-down switch cancels communications with the indoor unit, the indoor unit and the

remote control display “Transmission error – E5”. This is normal.

Summary of Contents for V Multi 100VNX

Page 98: ... 97 13 PAC T 197 Models FDT100VF1 125VF 140VF H H H H H C B A F G D G PJF000Z285 A ...

Page 101: ... 100 13 PAC T 197 Models FDEN60VF 71VF1 C2 C1 A B A B D C1 C2 C1 C2 E G F C PFA003Z817 ...

Page 116: ... 115 13 PAC T 197 b Wireless remote control RCN E1R 60 17 150 Unit mm ...

Page 291: ... 290 13 PAC T 197 261 12 PAC T 173 ー K ...

Page 590: ... 589 13 PAC T 197 3 8 SUPER LINK E BOARD SC ADNA E F ...

Page 591: ... 590 13 PAC T 197 ...