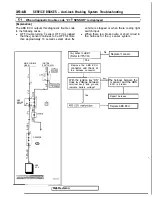

SERVICE BRAKES

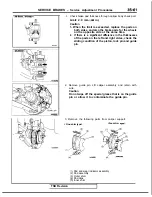

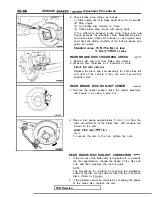

Service Adjustment Procedures

Delay

valve

Bleeder screw

(for the left rear brakes)

Bleeder screw

valve bolt

N m

ORDINARY AIR-BLEEDING PROCEDURES

Depress the brake pedal several times until resistance is

felt; then, with the pedal depressed, loosen the bleeder

screw

to

turn and then tighten it before the fluid

pressure is all gone.

(2) Release the brake pedal. Repeat this procedure until there

are no more air bubbles in the brake fluid.

AIR BLEEDING FROM DELAY VALVE

(1) Return the check valve bolt of the delay valve by about

one turn and then bleed the air by following the steps

described above in “Ordinary air-bleeding procedures”.

Caution

There is a delay valve bleeder screw for the left rear

wheel brake and for the right rear wheel brake, ensure

the correct one is used.

Be sure to tighten the check valve bolt at the specified

torque after completing the air bleeding.

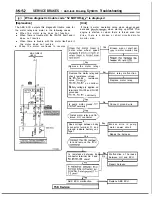

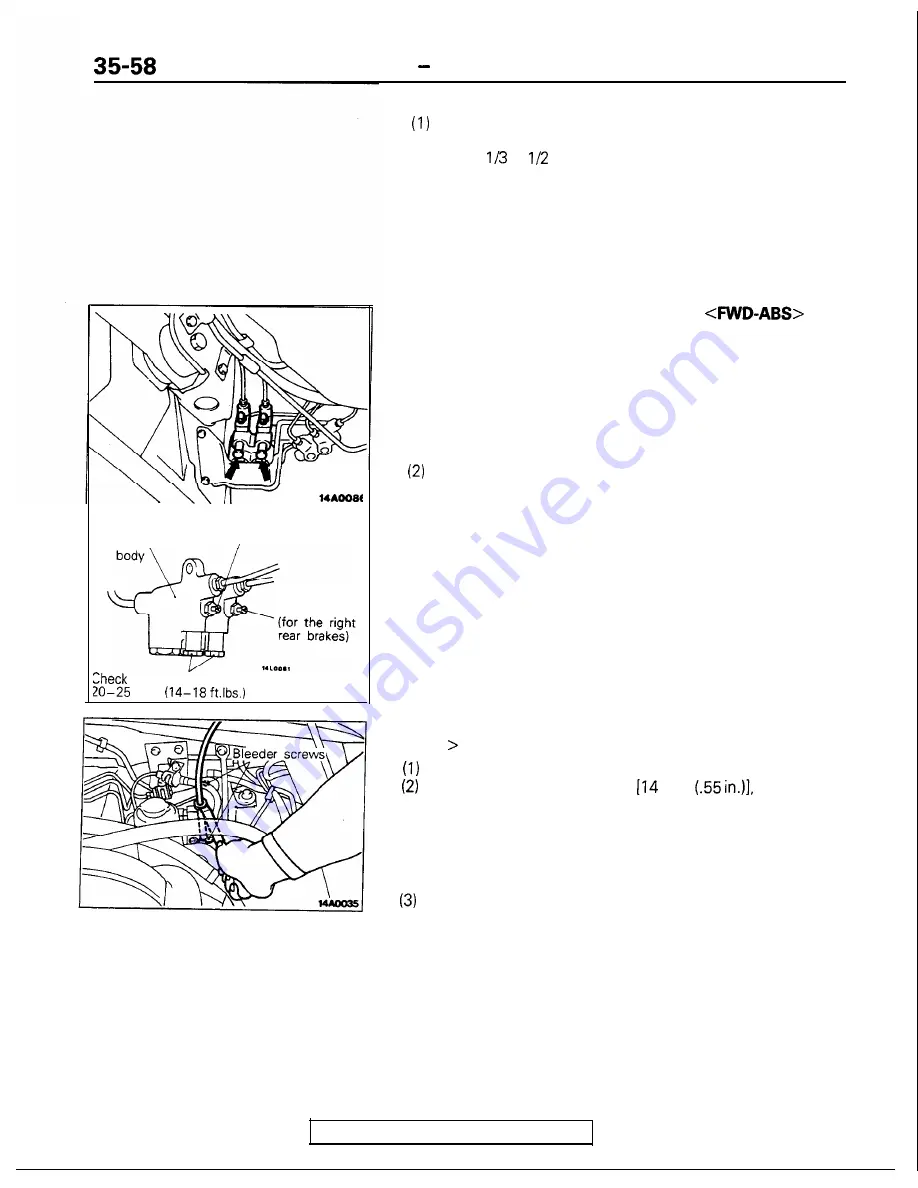

AIR BLEEDING FROM HYDRAULIC UNIT <VEHICLES WITH

A.B.S.

Attach the brake bleeder wrench to the bleeder screw.

Using an offset (box) wrench

mm

loosen the

bleeder screw.

Caution

Use an offset (box) wrench to open and close the

bleeder, not a spanner wrench, because a spanner

wrench might cause deformation of the hexagonal part.

Bleed the air by following the steps described above in

“Ordinary air-bleeding procedures”.

TSB Revision

Summary of Contents for 1989 Galant

Page 2: ......

Page 4: ...00 z NOTES ...

Page 274: ...13 132 NOTE ...

Page 586: ...NOTES ...

Page 650: ...NOTE ...

Page 664: ...NOTES ...

Page 688: ...NOTES ...

Page 690: ......

Page 692: ......

Page 694: ......

Page 696: ......

Page 698: ......

Page 700: ...c ...

Page 702: ......

Page 704: ......

Page 706: ......

Page 708: ......

Page 710: ......

Page 712: ......

Page 714: ......

Page 716: ......

Page 718: ......

Page 720: ......

Page 722: ......

Page 724: ......

Page 729: ...23 23 NOTES ...

Page 860: ...NOTES ...

Page 921: ...NOTES ...

Page 948: ...33B 9 NOTES ...

Page 1121: ...NOTES ...

Page 1200: ...SERVICE BRAKES Brake Pedal 35 79 Lubrication points Part A 14AO256 1 14UOO5l TSB Revision ...

Page 1273: ...NOTES t ...