ENGINE <6A1> -

On-vehicle Service

11B-6

POWER STEERING OIL PUMP AND AIR CONDITIONER

COMPRESSOR DRIVE BELT TENSION CHECK AND

ADJUSTMENT

11100130134

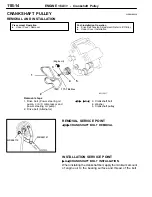

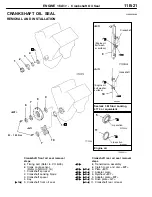

1. Use a belt tension gauge to check that the belt tension

is at the standard value at a point half-way between the

two pulleys (indicated by an arrow in the illustration).

In addition, press this section with a force of 98 N and

check that the amount of belt deflection is at the standard

value.

Standard value:

Items

When

checked

When a

used belt is

installed

When a new

belt is

installed

Tension N

490 - 686

539 - 637

784 - 980

Deflection

(Reference

value) mm

11.0 - 15.0

12.0 - 14.0

8.0-12.0

2. If the tension or deflection is outside the standard value,

adjust by the following procedure.

(1) Loosen tensioner pulley fixing nut A.

(2) Adjust the amount of belt deflection using adjusting

bolt B.

(3) Tighten fixing nut A.

Tightening torque: 49 Nm

(4) Check the belt deflection amount and tension, and

readjust if necessary.

Caution

Check after turning the crankshaft once or more

clockwise (right turn).

IGNITION TIMING CHECK

11100170280

1. Before inspection, set the vehicle to the pre-inspection

condition.

2. Connect the MUT-

II

to the diagnosis connector.

3. Set up a timing light.

4. Start the engine and run at idle.

5. Check that engine idle speed is within the standard value.

Standard value: 650

±

100 r/min

6. Select No.17 of the MUT-

II

Actuator test.

7. Check that basic ignition timing is within the standard

value.

Standard value: 5

_

BTDC

±

3

_

8. If the basic ignition timing is outside the standard value,

inspect the MPI system while referring to GROUP 13A

- Troubleshooting.

A

B

Power steering

oil pump pulley

Crankshaft

pulley

A/C compressor

pulley