ENGINE <6A1> -

On-vehicle Service

11B-8

5. Set the CO, HC tester.

6. Check the CO contents and the HC contents at idle.

Standard value

CO contents: 0.2% or less

HC contents: 100 ppm or less

7. If there is a deviation from the standard value, check

the following items:

D

Diagnosis output

D

Closed-loop control (When the closed-loop control

is normal, the output signal of the oxygen sensor

changes between 0- 400 mV and 600- 1,000 mV

at idle.)

D

Fuel pressure

D

Injector

D

Ignition coil, spark plug cable, spark plug

D

Leak in the EGR system and in the EGR valve

D

Evaporative emission control system

D

Compression pressure

NOTE

Replace the three way catalyst when the CO and HC

contents are not within the standard value, even though

the result of the inspection is normal on all items.

COMPRESSION PRESSURE CHECK

11100260482

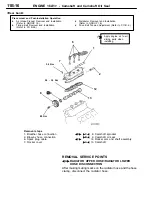

1. Before inspection, check that the engine oil, starter and

battery are normal. In addition, set the vehicle to the

pre-inspection condition.

2. Disconnect the spark plug cables.

3. Remove all of the spark plugs.

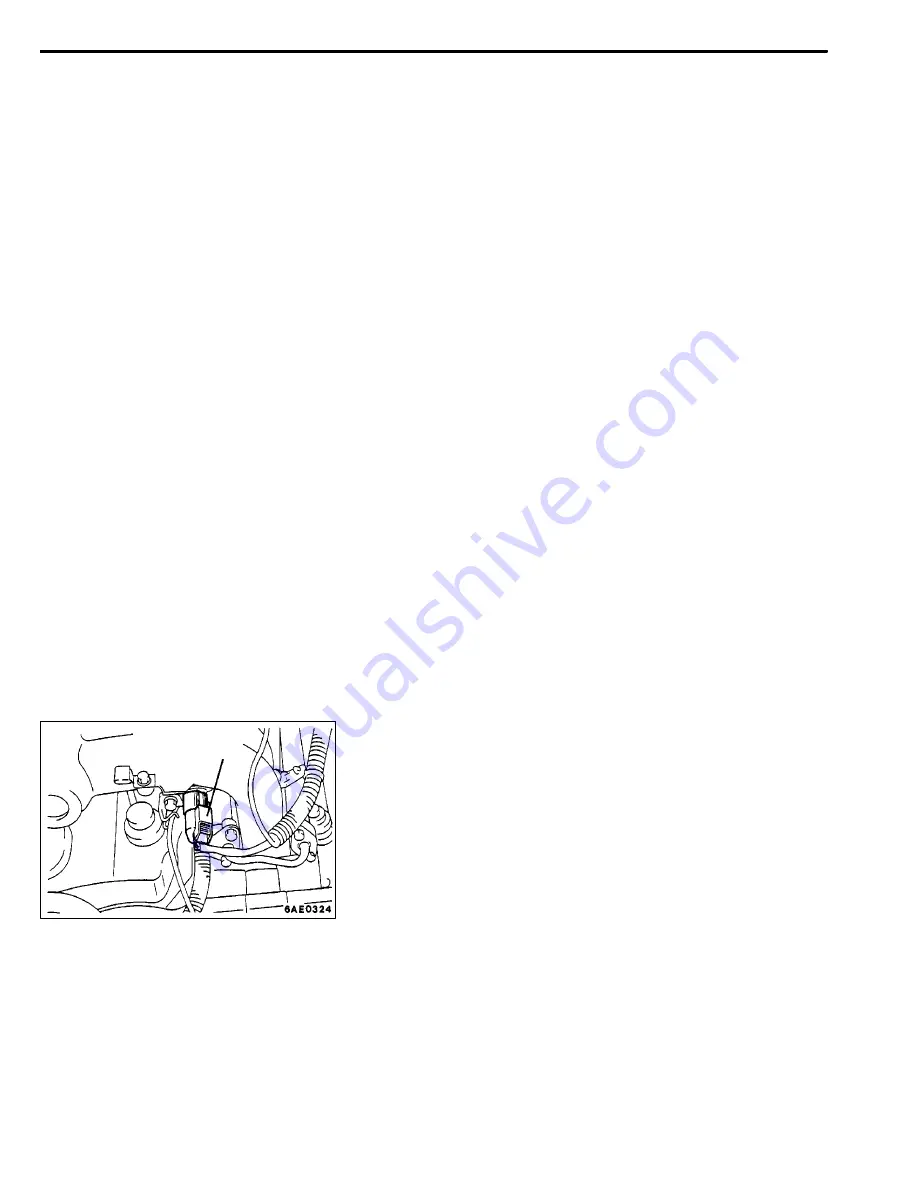

4. Disconnect the crank angle sensor connector.

NOTE

Doing this will prevent the engine-ECU from carrying out

ignition and fuel injection.

5. Cover the spark plug hole with a shop towel etc., and

after the engine has been cranked, check that no foreign

material is adhering to the shop towel.

Caution

1.

Keep away from the spark plug hole when

cranking.

2.

If compression is measured with water, oil, fuel,

etc., that has come from cracks inside the cylinder,

these materials will become heated and will gush

out from the spark plug hole, which is dangerous.

Crank angle

sensor connector