4G1 ENGINE (E–W) –

Pistons and Connecting Rods

(A–C) – (B–D)

L=

2

11A-11-3

PWEE9520

E

Nov. 1995

Mitsubishi Motors Corporation

2. CRANKSHAFT PIN OIL CLEARANCE (PLASTIC

GAUGE METHOD)

(1) Wipe all oil off the crankshaft pin and connecting rod

bearing.

(2) On the pin, place a plastic gauge that is cut to the same

length as the bearing’s width. The plastic gauge must

be centered on the pin in parallel with the pin’s axis.

(3) Gently place the connecting rod cap in position and tighten

the bolts to the specified torque.

(4) Remove the bolts and gently remove the connecting rod

cap.

(5) Measure the compressed part of the plastic gauge at

its widest point using the scale printed on the plastic

gauge bag.

Standard value: 0.02 – 0.04 mm

Limit: 0.1 mm

INSTALLATION SERVICE POINTS

"

A

A

PISTON PIN INSTALLATION

(1) When replacing the piston, read off the cylinder bore

size mark on the cylinder block as illustrated, and select

a piston according to the flowing table.

CYLINDER BORE SIZE

MARK

PISTON SIZE MARK

A

A

B

None

C

C

NOTE:

The piston size mark shows on the top of the piston.

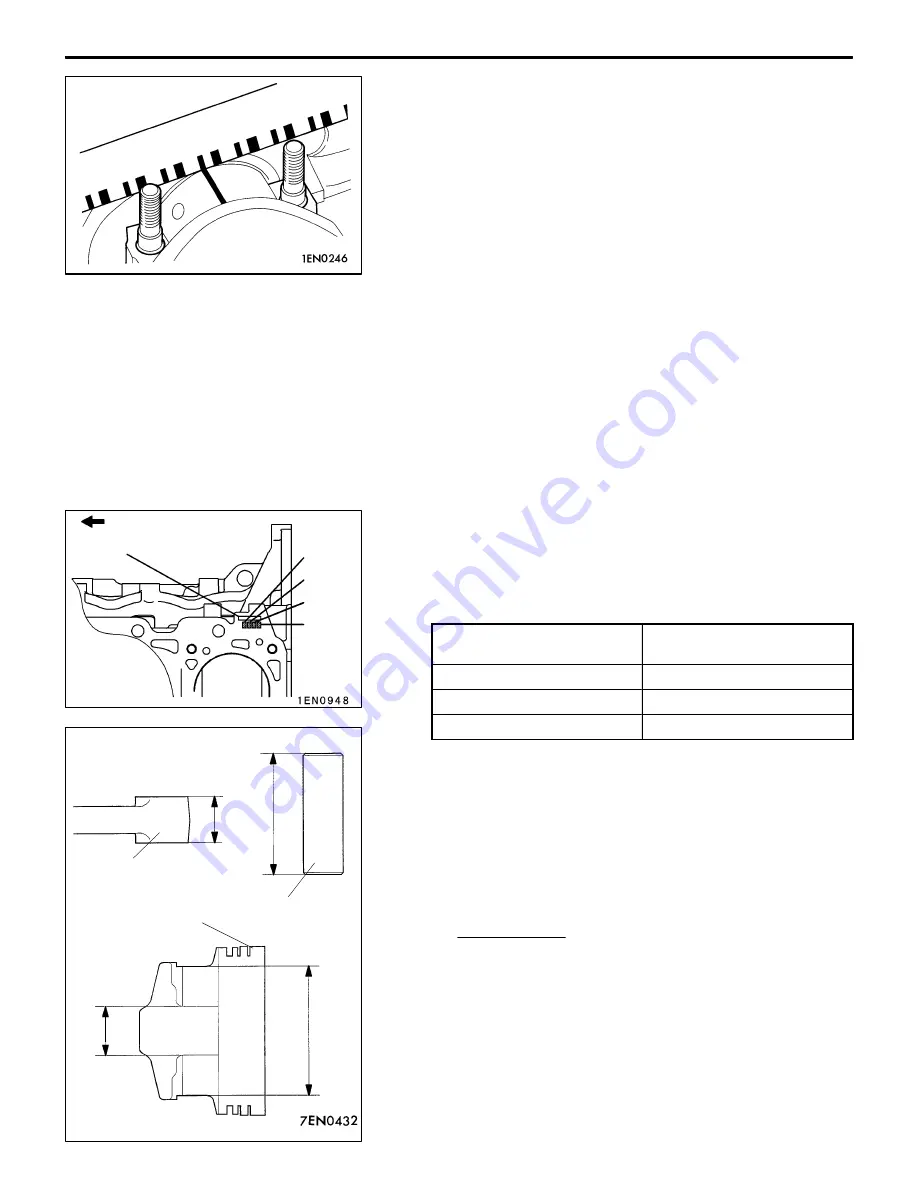

(2) Measure the following lengths (as shown):

A: Piston boss-to-piston boss outside dimension

B: Piston boss-to-piston boss inside dimension

C: Piston pin length

D: Connecting rod small end eye thickness

(3) Enter the measured values into the following formula:

(4) Insert the Push Rod (special tool) into the piston pin,

then fit Guide A (special tool).

(5) Fit the piston and connecting rod together such that their

front marks are on the same side.

(6) Apply engine oil to the outside of the piston pin.

(7) Into the front-mark side of the piston, insert the Guide

A, piston pin, and Push Rod, starting with guide A.

PWEE9520-G

E

Apr. 2003

Mitsubishi Motors Corporation

Revised

No. 1

No. 2

No. 3

No. 4

Timing belt side

Production date

Connecting rod

Piston

Piston pin

D

B

A

C

Summary of Contents for 4G1 series

Page 2: ...11A 0 2 PWEE9520 E Nov 1995 Mitsubishi Motors Corporation NOTES ...

Page 4: ...4G1 ENGINE E W General Information 11A 0 4 PWEE9520 E Nov 1995 Mitsubishi Motors Corporation ...

Page 22: ...NOTES ...

Page 139: ...Service Bulletins Click on the applicable bookmark to select the Service Bulletin ...