13

13-51

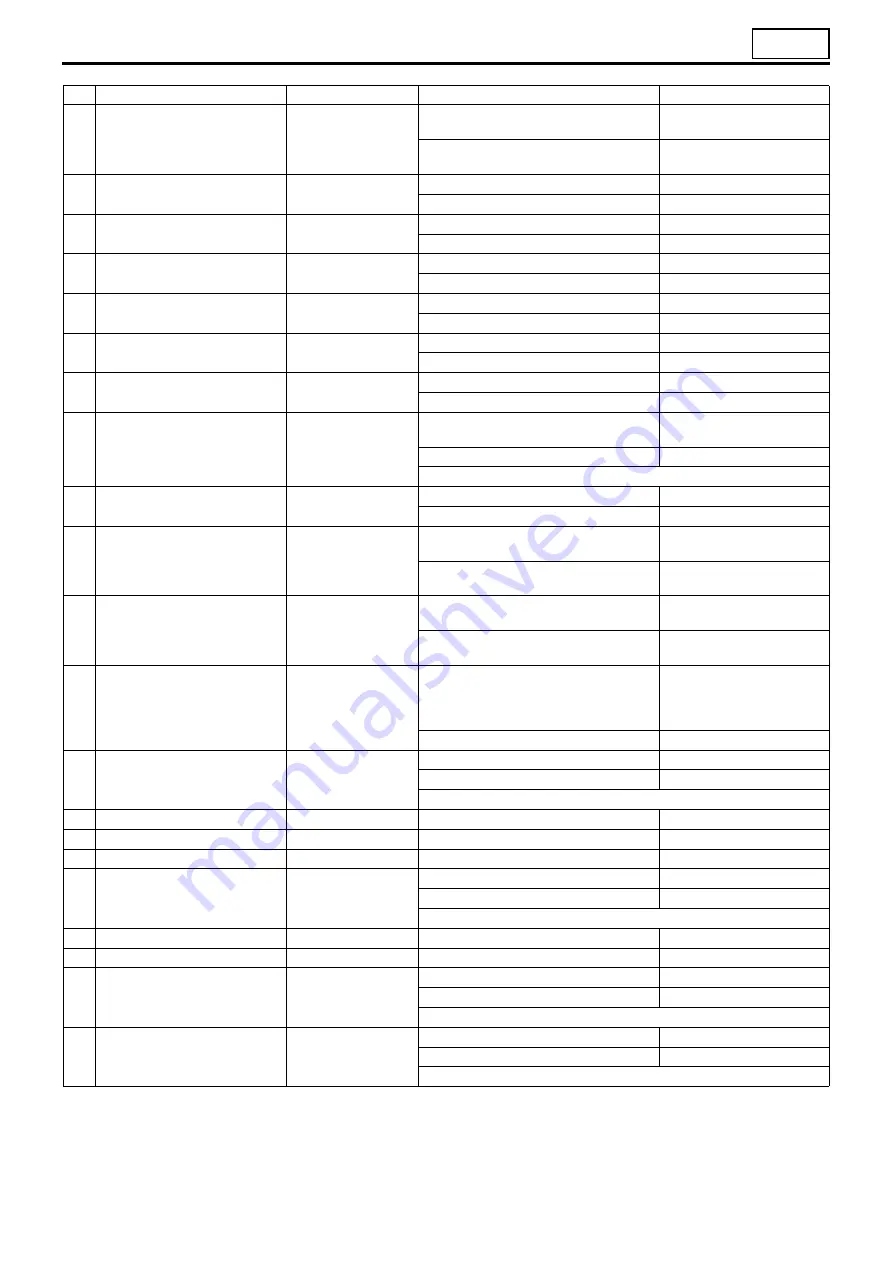

71 Starter SW (S)

ON/OFF

Engine cranked by means of starter

switch

ON

Starter switch in position except

START

OFF

72 Starter SW (M)

ON/OFF

Starter switch in ON position

ON

Starter switch in position except ON

OFF

73 Accel SW

ON/OFF

Accelerator pedal not pressed

ON

Accelerator pedal pressed

OFF

74 Powertard SW 1

ON/OFF

Powertard switch (1st step): ON

ON

Powertard switch (1st step): OFF

OFF

75 Powertard SW 2

ON/OFF

Powertard switch (2nd step): ON

ON

Powertard switch (2nd step): OFF

OFF

76 Clutch SW

ON/OFF

Clutch pedal pressed

ON

Clutch pedal not pressed

OFF

77 Neutral SW

ON/OFF

Transmission not in neutral

ON

Transmission in neutral

OFF

78 Idle Up Cancel SW

ON/OFF

Actuator test is performed

ON (5 times, for 1.5 sec.

each)

Actuator test is not performed

OFF

[Actuator test] B8: Idle Up Cancel SW

7C PTO SW

ON/OFF

Governor control switch ON

ON

Governor control switch OFF

OFF

7D Diagnosis SW

ON/OFF

Diagnosis switch OFF

(with connector connected)

ON

Diagnosis switch ON

(with connector disconnected)

OFF

7E Memory Clear SW

ON/OFF

Memory clear switch OFF

(with connector connected)

ON

Memory clear switch ON

(with connector disconnected)

OFF

7F Auxiliary Brake SW 1

ON/OFF

Operated under following conditions

•

Accelerator and clutch pedals are

pressed

•

Transmission in neutral position

ON

Other than above conditions

OFF

80 Powertard M/V

ON/OFF

Powertard operating

ON

Powertard not operating

OFF

[Actuator test] A6: Powertard M/V

82 VGT M/V 1

ON/OFF

See Gr15.

–

83 VGT M/V 2

ON/OFF

See Gr15.

–

84 VGT M/V 3

ON/OFF

See Gr15.

–

85 Auxiliary Brake Indicator Lamp ON/OFF

Auxiliary brake operating

ON

Auxiliary brake not operating

OFF

[Actuator test] AE: Auxiliary Brake Indicator Lamp

88 Starter Safety Relay

ON/OFF

See Gr54.

–

89 EDU Power Relay

ON/OFF

See Gr17.

–

8A MIL LAMP

ON/OFF

Starter switch ON (engine not started) ON

No error after engine startup

OFF

[Actuator test] B3: MIL Lamp

8B Diagnosis Lamp

ON/OFF

Starter switch ON (engine not started) ON

No error after engine startup

OFF

[Actuator test] B4: Diagnosis Lamp

No.

Item

Data

Inspection condition

Requirement

Summary of Contents for 6M70

Page 29: ...M E M O 11 19 11 ...

Page 35: ...M E M O 11 25 11 ...

Page 36: ...11 26 MITSUBISHI 6M70 ROCKER COVER ROCKER AND SHAFT ...

Page 40: ...11 30 MITSUBISHI 6M70 CAMSHAFT AND ROCKER CASE ...

Page 47: ...M E M O 11 37 11 ...

Page 48: ...11 38 MITSUBISHI 6M70 CYLINDER HEAD AND VALVE MECHANISM ...

Page 63: ...M E M O 11 53 11 ...

Page 71: ...M E M O 11 61 11 ...

Page 77: ...M E M O 11 67 11 ...

Page 81: ...M E M O 11 71 11 ...

Page 98: ...11 88 MITSUBISHI 6M70 CRANKSHAFT AND CRANKCASE ...

Page 127: ...M E M O 12 21 12 ...

Page 129: ...M E M O 12 23 12 ...

Page 135: ...M E M O 13 3 13 ...

Page 138: ...13 6 1 1 Mitsubishi 6M70 Supply pump STRUCTURE AND OPERATION ...

Page 150: ...13 18 10 Electronic control unit connection diagram STRUCTURE AND OPERATION ...

Page 151: ...13 13 19 ...

Page 155: ...M E M O 13 23 13 ...

Page 185: ...M E M O 13 53 13 ...

Page 189: ...M E M O 13 57 13 ...

Page 205: ...M E M O 13 73 13 ...

Page 211: ...M E M O 13 79 13 ...

Page 215: ...M E M O 13 83 13 ...

Page 219: ...M E M O 13 87 13 ...

Page 225: ...M E M O 13 93 13 ...

Page 226: ...13 94 INSTALLED LOCATIONS OF PARTS ...

Page 227: ...13 13 95 ...

Page 228: ...13 96 INSTALLED LOCATIONS OF PARTS ...

Page 229: ...13 13 97 ...

Page 230: ...13 98 INSTALLED LOCATIONS OF PARTS ...

Page 231: ...13 13 99 ...

Page 232: ...13 100 MITSUBISHI 6M70 INSTALLED LOCATIONS OF PARTS ...

Page 233: ...13 13 101 ...

Page 234: ...13 102 ELECTRIC CIRCUIT DIAGRAM ...

Page 235: ...13 13 103 ...

Page 236: ...13 104 ELECTRIC CIRCUIT DIAGRAM ...

Page 237: ...13 13 105 ...

Page 238: ...13 106 ELECTRIC CIRCUIT DIAGRAM ...

Page 241: ...14 14 3 1 Mitsubishi 6M70 Cooling System Flow of Coolant STRUCTURE AND OPERATION ...

Page 252: ...14 14 Periphery of Engine DISCONNECTION AND CONNECTION OF HOSES AND PIPES ...

Page 271: ...M E M O 14 33 14 ...

Page 286: ...M E M O 15 13 15 ...

Page 295: ...15 22 7 Installed Locations of Parts TURBOCHARGER CONTROL SYSTEM ...

Page 296: ...15 15 23 ...

Page 297: ...15 24 TURBOCHARGER CONTROL SYSTEM ...

Page 298: ...15 15 25 ...

Page 299: ...15 26 TURBOCHARGER CONTROL SYSTEM ...

Page 300: ...15 15 27 ...

Page 301: ...15 28 TURBOCHARGER CONTROL SYSTEM ...

Page 302: ...M E M O 15 29 15 ...

Page 303: ...15 30 8 Electric Circuit Diagram TURBOCHARGER CONTROL SYSTEM ...

Page 304: ...15 15 31 ...

Page 305: ...15 32 TURBOCHARGER CONTROL SYSTEM ...

Page 306: ...M E M O 15 33 15 ...

Page 330: ...M E M O 15 57 15 ...

Page 340: ...17 6 1 3 Electronic control unit connection diagram STRUCTURE AND OPERATION ...

Page 343: ...M E M O 17 9 17 ...

Page 351: ...M E M O 17 17 17 ...

Page 352: ...17 18 8 Installed Locations of Parts EXHAUST GAS RECIRCULATION SYSTEM ...

Page 353: ...17 17 19 ...

Page 354: ...17 20 EXHAUST GAS RECIRCULATION SYSTEM ...

Page 355: ...17 17 21 ...

Page 356: ...17 22 EXHAUST GAS RECIRCULATION SYSTEM ...

Page 357: ...17 17 23 ...

Page 358: ...17 24 9 Electric Circuit Diagram EXHAUST GAS RECIRCULATION SYSTEM ...

Page 359: ...17 17 25 ...

Page 360: ...17 26 MITSUBISHI 6M70 EGR VALVE EGR MAGNETIC VALVE EGR PIPE AND EGR COOLER ...