00-22

1. Diagnosis Codes

•

Diagnosis codes indicate the faulty sections of the vehicle.

•

A fault can be repaired by reading out the diagnosis code(s) stored in the control unit and performing the remedy

for that code(s).

•

Diagnosis codes can be displayed in the following two methods. Select either of them according to the system to

be diagnosed.

•

Using a Multi-Use Tester

•

Using flashing of a warning lamp on meter cluster

•

The table below indicates the systems for which diagnosis codes can be displayed and the methods usable for in-

dividual systems.

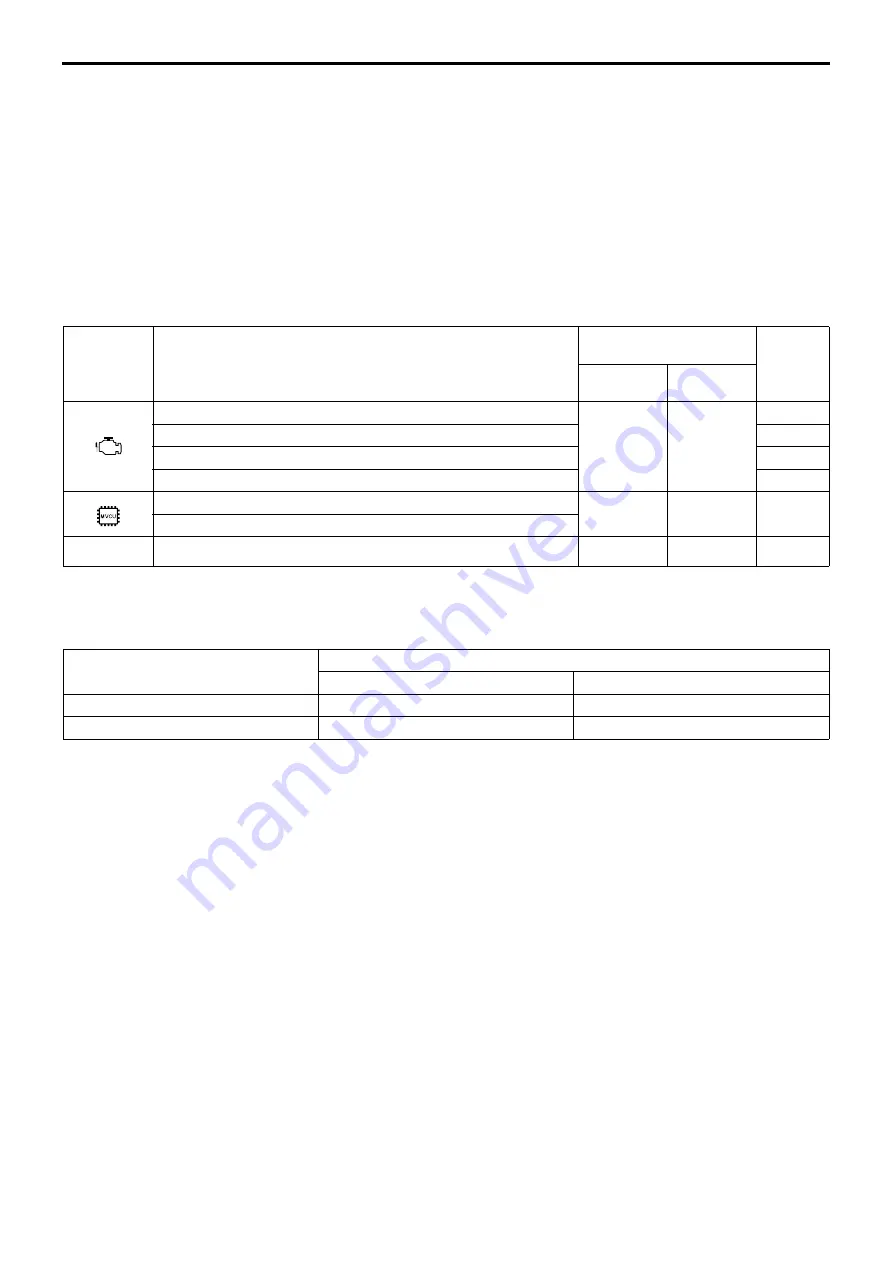

1.1 Systems and diagnosis code displaying methods

1.2 Types of diagnosis codes

•

There are two types of diagnosis code output method depending on the system: one has a distinction of present

and past codes, and the other does not have such a distinction.

(1) The system that has a distinction of present and past diagnosis codes

(1.1) Present diagnosis code

•

Fault developed in the vehicle after the starter switch is set to ON is indicated by corresponding diagnosis code.

•

The fault warning lamp is lit at the same time.

(1.2) Past diagnosis code

•

Past fault developed in the vehicle is indicated by corresponding diagnosis code stored in the memory of the elec-

tronic control unit.

•

With the vehicle restored to its normal condition or the starter switch turned from OFF to ON after inspection or re-

pair against present diagnosis codes, the present diagnosis code is stored as past diagnosis codes in the memory

of the electronic control unit.

•

When reading out the past diagnosis codes, the warning lamp does not illuminate as such codes do not indicate

the current fault.

(2) The system that does not have a distinction of present and past diagnosis codes

•

The present and past diagnosis codes are displayed together without distinction.

Warning

lamp

System

Diagnosis codes

displaying methods

Reference

Gr

Multi-Use

Tester

Flashing of

warning lamp

Common rail

O

O

13

Turbocharger

15

Exhaust gas recirculation

17

Starter continuous energizing preventing function

54

Vehicle speed limiting (SLD)

O

O

54

Auto cruise

–

Full auto air conditioner

O

O

55

System

Diagnosis code

With distinction of present and past

Without distinction

Except below

O

–

Full auto air conditioner

–

O

DIAGNOSIS CODES

Summary of Contents for 6M70

Page 29: ...M E M O 11 19 11 ...

Page 35: ...M E M O 11 25 11 ...

Page 36: ...11 26 MITSUBISHI 6M70 ROCKER COVER ROCKER AND SHAFT ...

Page 40: ...11 30 MITSUBISHI 6M70 CAMSHAFT AND ROCKER CASE ...

Page 47: ...M E M O 11 37 11 ...

Page 48: ...11 38 MITSUBISHI 6M70 CYLINDER HEAD AND VALVE MECHANISM ...

Page 63: ...M E M O 11 53 11 ...

Page 71: ...M E M O 11 61 11 ...

Page 77: ...M E M O 11 67 11 ...

Page 81: ...M E M O 11 71 11 ...

Page 98: ...11 88 MITSUBISHI 6M70 CRANKSHAFT AND CRANKCASE ...

Page 127: ...M E M O 12 21 12 ...

Page 129: ...M E M O 12 23 12 ...

Page 135: ...M E M O 13 3 13 ...

Page 138: ...13 6 1 1 Mitsubishi 6M70 Supply pump STRUCTURE AND OPERATION ...

Page 150: ...13 18 10 Electronic control unit connection diagram STRUCTURE AND OPERATION ...

Page 151: ...13 13 19 ...

Page 155: ...M E M O 13 23 13 ...

Page 185: ...M E M O 13 53 13 ...

Page 189: ...M E M O 13 57 13 ...

Page 205: ...M E M O 13 73 13 ...

Page 211: ...M E M O 13 79 13 ...

Page 215: ...M E M O 13 83 13 ...

Page 219: ...M E M O 13 87 13 ...

Page 225: ...M E M O 13 93 13 ...

Page 226: ...13 94 INSTALLED LOCATIONS OF PARTS ...

Page 227: ...13 13 95 ...

Page 228: ...13 96 INSTALLED LOCATIONS OF PARTS ...

Page 229: ...13 13 97 ...

Page 230: ...13 98 INSTALLED LOCATIONS OF PARTS ...

Page 231: ...13 13 99 ...

Page 232: ...13 100 MITSUBISHI 6M70 INSTALLED LOCATIONS OF PARTS ...

Page 233: ...13 13 101 ...

Page 234: ...13 102 ELECTRIC CIRCUIT DIAGRAM ...

Page 235: ...13 13 103 ...

Page 236: ...13 104 ELECTRIC CIRCUIT DIAGRAM ...

Page 237: ...13 13 105 ...

Page 238: ...13 106 ELECTRIC CIRCUIT DIAGRAM ...

Page 241: ...14 14 3 1 Mitsubishi 6M70 Cooling System Flow of Coolant STRUCTURE AND OPERATION ...

Page 252: ...14 14 Periphery of Engine DISCONNECTION AND CONNECTION OF HOSES AND PIPES ...

Page 271: ...M E M O 14 33 14 ...

Page 286: ...M E M O 15 13 15 ...

Page 295: ...15 22 7 Installed Locations of Parts TURBOCHARGER CONTROL SYSTEM ...

Page 296: ...15 15 23 ...

Page 297: ...15 24 TURBOCHARGER CONTROL SYSTEM ...

Page 298: ...15 15 25 ...

Page 299: ...15 26 TURBOCHARGER CONTROL SYSTEM ...

Page 300: ...15 15 27 ...

Page 301: ...15 28 TURBOCHARGER CONTROL SYSTEM ...

Page 302: ...M E M O 15 29 15 ...

Page 303: ...15 30 8 Electric Circuit Diagram TURBOCHARGER CONTROL SYSTEM ...

Page 304: ...15 15 31 ...

Page 305: ...15 32 TURBOCHARGER CONTROL SYSTEM ...

Page 306: ...M E M O 15 33 15 ...

Page 330: ...M E M O 15 57 15 ...

Page 340: ...17 6 1 3 Electronic control unit connection diagram STRUCTURE AND OPERATION ...

Page 343: ...M E M O 17 9 17 ...

Page 351: ...M E M O 17 17 17 ...

Page 352: ...17 18 8 Installed Locations of Parts EXHAUST GAS RECIRCULATION SYSTEM ...

Page 353: ...17 17 19 ...

Page 354: ...17 20 EXHAUST GAS RECIRCULATION SYSTEM ...

Page 355: ...17 17 21 ...

Page 356: ...17 22 EXHAUST GAS RECIRCULATION SYSTEM ...

Page 357: ...17 17 23 ...

Page 358: ...17 24 9 Electric Circuit Diagram EXHAUST GAS RECIRCULATION SYSTEM ...

Page 359: ...17 17 25 ...

Page 360: ...17 26 MITSUBISHI 6M70 EGR VALVE EGR MAGNETIC VALVE EGR PIPE AND EGR COOLER ...