15-10

1. Measurement and Adjustment of Turbocharger Boost Pressure

Service standards

(1) Preparation

•

Put the transmission in N range.

•

Turn the steering wheel in neutral position.

•

Turn off all lamps and accessories.

•

Connect the Multi-Use Tester.

•

Check diagnosis code of each electronic control system. If any

fault exists, rectify it.

•

Warm up the engine until the engine coolant has been heated to

more than 60

°

C. (verify from Service Data “2E: Water Tempera-

ture”)

•

Check that the non-load minimum speed (idling speed) is as

specified. (See Gr13.)

(2) Measurement and correction of boost pressure

•

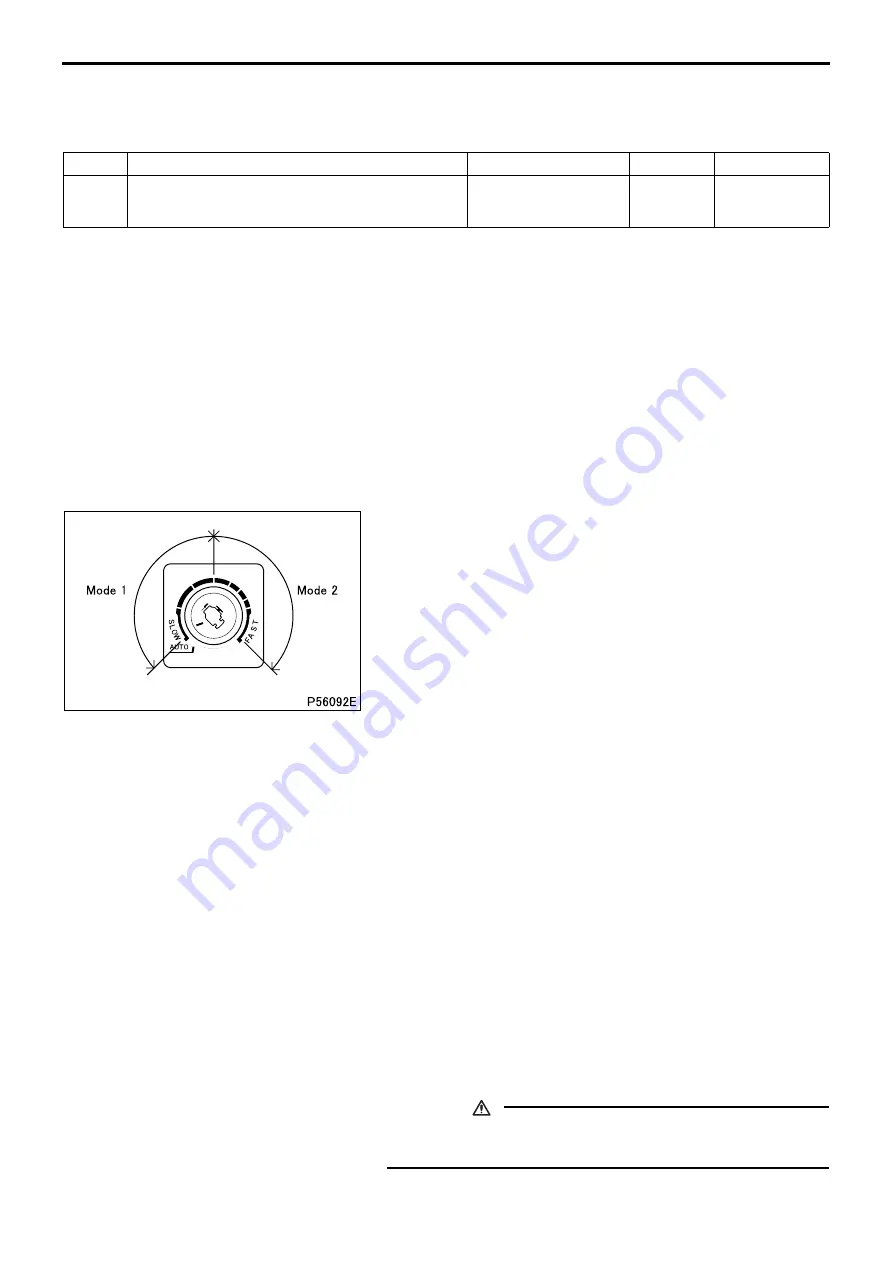

Turn the idle adjust dial to any position within the illustrated

range of Mode 1.

•

Select [Engine Control] on the system select screen of the Multi-

Use Tester, then execute [BA: VGT Test] from [Actuator Tests].

•

When [BA: VGT Test] is executed, the engine speed should be

automatically increased to 1600 rpm (No. 2 magnetic valve acti-

vated).

•

Maintain the state of [BA: VGT Test] having been executed (for 5

to 15 minutes) until boost pressure is stabilized.

•

Measure the following items from among [Service Data].

26: Boost pressure (actual boost pressure)

2B: Intake air temperature (actual intake air temperature)

30: Atmospheric pressure (actual atmospheric pressure)

•

Obtain corrected boost pressure by calculating above Service

Data.

[Correction with intake air temperature]

Corrected boost pressure [kPa] = Measured boost pr 0.43

(measured intake air temperature - 25)

[Correction with boost temperature (Exhaust gas recirculation

temperature)]

Corrected boost pressure [kPa] = Measured boost pr 0.02

(measured boost temperature - 33)

[Correction with atmospheric pressure]

Corrected boost pressure [kPa] = Measured boost pressure -

(measured atmospheric pressure - 101.5)

•

If corrected boost pressure in any case above deviates from the

standard value, adjust the turbocharger.

CAUTION

• If the adjusting range of the air cylinder shaft exceeds ±1.5

turns, check the turbocharger.

Location

Maintenance item

Standard value

Limit

Remedy

–

Boost pressure

(when VGT test performed with ambient temperature at

25

°

C and atmospheric pressure at 101.5 kPa)

157

±

7 kPa

–

Adjust

ON-VEHICLE INSPECTION AND ADJUSTMENT

Summary of Contents for 6M70

Page 29: ...M E M O 11 19 11 ...

Page 35: ...M E M O 11 25 11 ...

Page 36: ...11 26 MITSUBISHI 6M70 ROCKER COVER ROCKER AND SHAFT ...

Page 40: ...11 30 MITSUBISHI 6M70 CAMSHAFT AND ROCKER CASE ...

Page 47: ...M E M O 11 37 11 ...

Page 48: ...11 38 MITSUBISHI 6M70 CYLINDER HEAD AND VALVE MECHANISM ...

Page 63: ...M E M O 11 53 11 ...

Page 71: ...M E M O 11 61 11 ...

Page 77: ...M E M O 11 67 11 ...

Page 81: ...M E M O 11 71 11 ...

Page 98: ...11 88 MITSUBISHI 6M70 CRANKSHAFT AND CRANKCASE ...

Page 127: ...M E M O 12 21 12 ...

Page 129: ...M E M O 12 23 12 ...

Page 135: ...M E M O 13 3 13 ...

Page 138: ...13 6 1 1 Mitsubishi 6M70 Supply pump STRUCTURE AND OPERATION ...

Page 150: ...13 18 10 Electronic control unit connection diagram STRUCTURE AND OPERATION ...

Page 151: ...13 13 19 ...

Page 155: ...M E M O 13 23 13 ...

Page 185: ...M E M O 13 53 13 ...

Page 189: ...M E M O 13 57 13 ...

Page 205: ...M E M O 13 73 13 ...

Page 211: ...M E M O 13 79 13 ...

Page 215: ...M E M O 13 83 13 ...

Page 219: ...M E M O 13 87 13 ...

Page 225: ...M E M O 13 93 13 ...

Page 226: ...13 94 INSTALLED LOCATIONS OF PARTS ...

Page 227: ...13 13 95 ...

Page 228: ...13 96 INSTALLED LOCATIONS OF PARTS ...

Page 229: ...13 13 97 ...

Page 230: ...13 98 INSTALLED LOCATIONS OF PARTS ...

Page 231: ...13 13 99 ...

Page 232: ...13 100 MITSUBISHI 6M70 INSTALLED LOCATIONS OF PARTS ...

Page 233: ...13 13 101 ...

Page 234: ...13 102 ELECTRIC CIRCUIT DIAGRAM ...

Page 235: ...13 13 103 ...

Page 236: ...13 104 ELECTRIC CIRCUIT DIAGRAM ...

Page 237: ...13 13 105 ...

Page 238: ...13 106 ELECTRIC CIRCUIT DIAGRAM ...

Page 241: ...14 14 3 1 Mitsubishi 6M70 Cooling System Flow of Coolant STRUCTURE AND OPERATION ...

Page 252: ...14 14 Periphery of Engine DISCONNECTION AND CONNECTION OF HOSES AND PIPES ...

Page 271: ...M E M O 14 33 14 ...

Page 286: ...M E M O 15 13 15 ...

Page 295: ...15 22 7 Installed Locations of Parts TURBOCHARGER CONTROL SYSTEM ...

Page 296: ...15 15 23 ...

Page 297: ...15 24 TURBOCHARGER CONTROL SYSTEM ...

Page 298: ...15 15 25 ...

Page 299: ...15 26 TURBOCHARGER CONTROL SYSTEM ...

Page 300: ...15 15 27 ...

Page 301: ...15 28 TURBOCHARGER CONTROL SYSTEM ...

Page 302: ...M E M O 15 29 15 ...

Page 303: ...15 30 8 Electric Circuit Diagram TURBOCHARGER CONTROL SYSTEM ...

Page 304: ...15 15 31 ...

Page 305: ...15 32 TURBOCHARGER CONTROL SYSTEM ...

Page 306: ...M E M O 15 33 15 ...

Page 330: ...M E M O 15 57 15 ...

Page 340: ...17 6 1 3 Electronic control unit connection diagram STRUCTURE AND OPERATION ...

Page 343: ...M E M O 17 9 17 ...

Page 351: ...M E M O 17 17 17 ...

Page 352: ...17 18 8 Installed Locations of Parts EXHAUST GAS RECIRCULATION SYSTEM ...

Page 353: ...17 17 19 ...

Page 354: ...17 20 EXHAUST GAS RECIRCULATION SYSTEM ...

Page 355: ...17 17 21 ...

Page 356: ...17 22 EXHAUST GAS RECIRCULATION SYSTEM ...

Page 357: ...17 17 23 ...

Page 358: ...17 24 9 Electric Circuit Diagram EXHAUST GAS RECIRCULATION SYSTEM ...

Page 359: ...17 17 25 ...

Page 360: ...17 26 MITSUBISHI 6M70 EGR VALVE EGR MAGNETIC VALVE EGR PIPE AND EGR COOLER ...