5 - 64

MELSEC-A

5 DATA USED FOR POSITIONING CONTROL

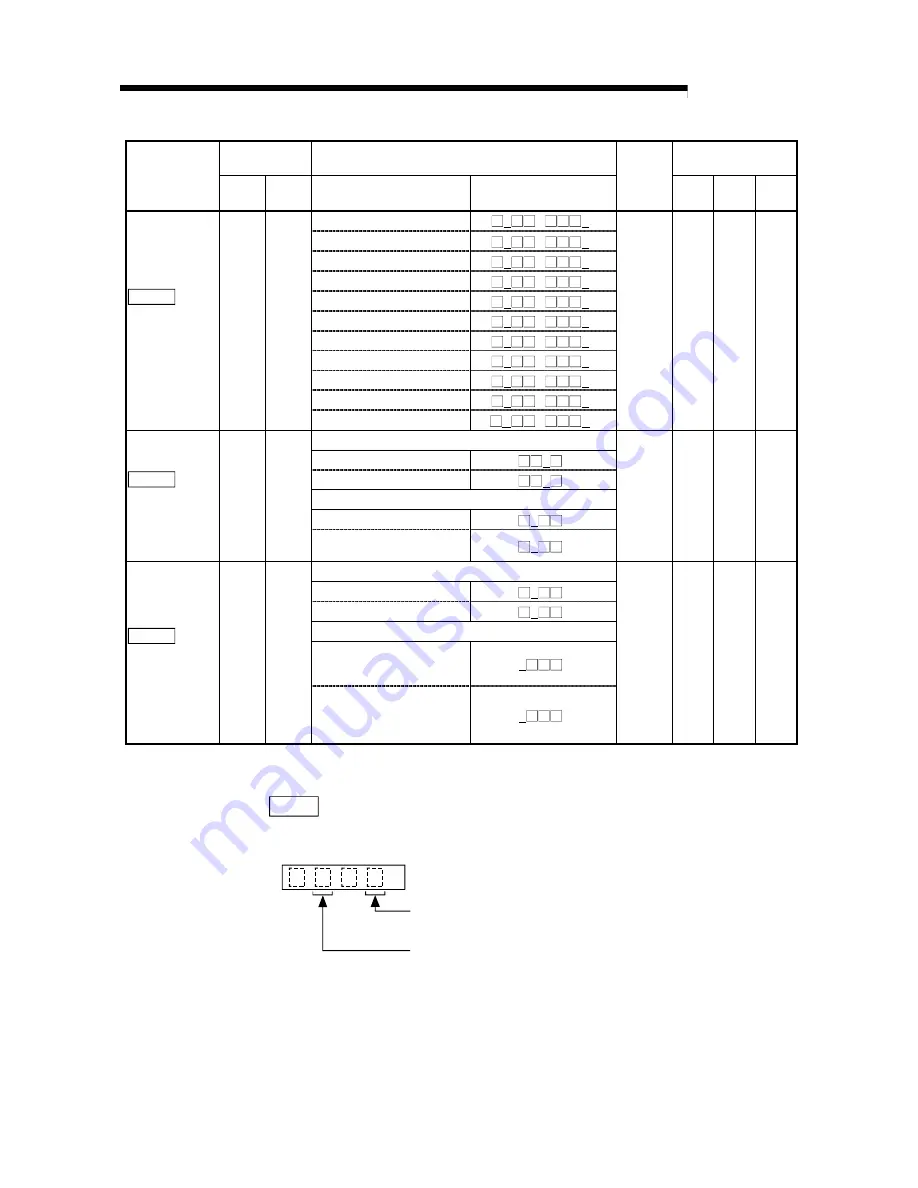

Servo amplifier

side parameter

Setting value, setting range

Setting value buffer

memory address

Item

No.

Abbre-

viation

Value set with peripheral

device

Value set with sequence

program

Default

value

Axis 1 Axis 2 Axis 3

0 : Servomotor speed

0

H

/

0

H

1 :

Torque

1

H

/

1

H

2 : Servomotor speed (+)

2

H

/

2

H

3 : Torque (+)

3

H

/

3

H

4 : Current command

4

H

/

4

H

5 : Command speed

5

H

/

5

H

6 : Droop pulse 1/1

6

H

/

6

H

7 : Droop pulse 1/4

7

H

/

7

H

8 : Droop pulse 1/16

8

H

/

8

H

9 : Droop pulse 1/32

9

H

/

9

H

Pr.122

Monitor output

mode

selection

No.22 MOD

A : Droop pulse 1/64

A

H

/

A

H

0001

H

122 272 422

Carrier frequency selection

0 : 2.25KHz (Standard)

0

H

3 : 9.0KHz (Low noise)

3

H

Serial encoder cable selection

0 :

2-wire

0

H

Pr.123

Option

function 1

No.23 *OP1

1 : 4-wire (Supports long

distance cables)

1

H

0000

H

123 273 423

Motor-less operation selection

0 :

Invalid

0

H

1 :

Valid

1

H

Solenoid brake interlock output selection

0 : Independent of motor

speed (Output under

specific condition)

0

H

Pr.124

Option

function 2

No.24 *OP2

1 : Output under specific

condition at motor

speed of zero speed or

less

1

H

0000

H

124 274 424

* This parameter is made valid when the servo amplifier is powered OFF, then ON again after it has been transferred

from the AD75 to the servo amplifier.

Pr.122

Monitor output mode selection

Select the signals to be output from the analog monitor CH1 and CH2 of the servo

amplifier.

H

Monitor output 2 selection

Set any of 0 to A. (Refer to the settings of the following monitor output 1)

Monitor output 1 selection

0: Servomotor speed

1: Torque

2: Servomotor speed (+)

3: Torque (+)

4: Current command

5: Command speed

6: Droop pulse 1/1

7: Droop pulse 1/4

8: Droop pulse 1/16

9: Droop pulse 1/32

A: Droop pulse 1/64

0

0

Summary of Contents for A1SD75M1

Page 2: ......

Page 20: ...A 18 MEMO...

Page 22: ...MEMO...

Page 27: ...1 5 MELSEC A 1 PRODUCT OUTLINE MEMO...

Page 42: ...1 20 MELSEC A 1 PRODUCT OUTLINE MEMO...

Page 52: ...2 10 MELSEC A 2 SYSTEM CONFIGURATION MEMO...

Page 111: ...5 21 MELSEC A 5 DATA USED FOR POSITIONING CONTROL MEMO...

Page 115: ...5 25 MELSEC A 5 DATA USED FOR POSITIONING CONTROL MEMO...

Page 123: ...5 33 MELSEC A 5 DATA USED FOR POSITIONING CONTROL MEMO...

Page 127: ...5 37 MELSEC A 5 DATA USED FOR POSITIONING CONTROL MEMO...

Page 167: ...5 77 MELSEC A 5 DATA USED FOR POSITIONING CONTROL MEMO...

Page 193: ...5 103 MELSEC A 5 DATA USED FOR POSITIONING CONTROL MEMO...

Page 276: ...5 186 MELSEC A 5 DATA USED FOR POSITIONING CONTROL MEMO...

Page 332: ...7 18 MELSEC A 7 MEMORY CONFIGURATION AND DATA PROCESS MEMO...

Page 334: ...MEMO...

Page 422: ...9 64 MELSEC A 9 MAIN POSITIONING CONTROL MEMO...

Page 446: ...10 24 MELSEC A 10 ADVANCED POSITIONING CONTROL MEMO...

Page 472: ...11 26 MELSEC A 11 MANUAL CONTROL MEMO...

Page 576: ...12 104 MELSEC A 12 CONTROL AUXILIARY FUNCTIONS MEMO...

Page 745: ......