Appendix - 45

MELSEC-A

APPENDICES

SPEED LOOP GAIN

This is one item in the servo parameters of the

positioning data. It expresses the speed of the

control response during speed control. When

the load inertia moment ratio increases, the

control system speed response decreases and

the operation may become unstable. If this

happens, the operation can be improved by

raising this setting value.

The overshoot will become larger if the speed

loop gain is raised too far, and motor vibration

noise will occur during operation and when

stopped.

SPEED LOOP MODE

This is one servo control mode used in

positioning. It is a mode for carrying out speed

control. Refer to "POSITION LOOP MODE".

SPEED/POSITION CONTROL

CHANGEOVER MODE

This is one method used for positioning. It is

an application for operations such as high-

speed movement to a point unrelated to

positioning, then set dimension movement

from the changeover signal activation point.

Start

Changeover signal

High speed

Increment positioning

START COMPLETE

This signal gives an immediate response

notifying the user that the AD75 that was

started is now in a normal state and can start

positioning.

STARTING AXIS

One of the AD75 axis system axes (axis 1,

axis 2, or axis 3) or the reference axis for the

interpolation operation is designated as the

starting axis.

STATUS

Data showing the state of the machine.

Collectively refers to signals that turn ON when

the battery voltage drops, during zero point

requests, during dwell time, etc.

STEP FUNCTION

When the operation is designed so that

several positioning data Nos. are

consecutively run, this function can be used to

carry out a test operation for 1 data item at a

time.

STOP SETTLING TIME

Refer to the term "DWELL TIME".

STOP SIGNAL

In positioning control, this is the input signal X

that directly stops the operation from an

external source.

The operation stops when the external STOP

signal (a contact) turns ON (continuity), and X

turns ON.

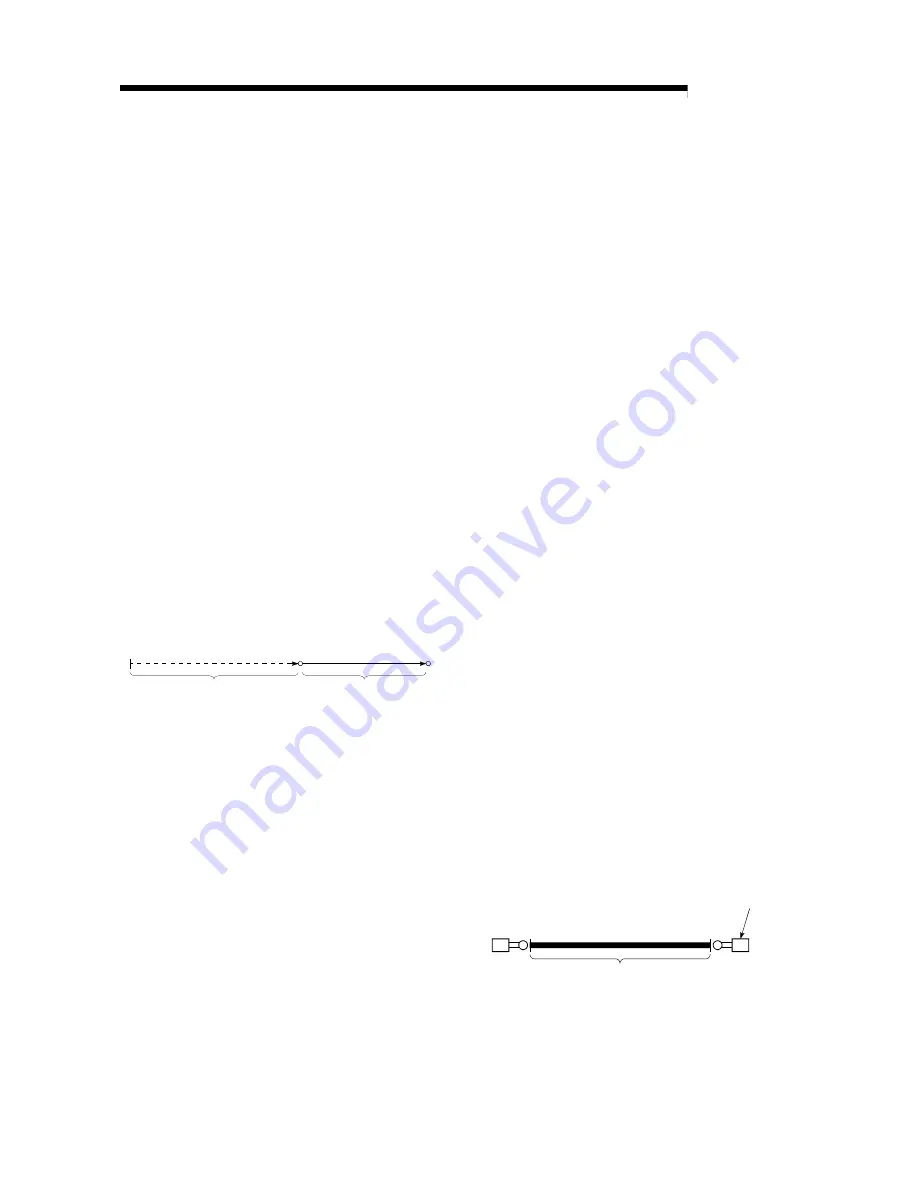

STROKE

The stroke is the variation in the operation by

the distance from a stopped state to the next

stopped state after a movement.

STROKE LIMIT

This is the range in which a positioning

operation is possible, or the range in which the

machine can be moved without damage

occurring.

For operations using a worm gear, the stroke

limit is determined by the length of the screw.

For operations using a fixed-dimension feed, it

is determined by the max. dimension to be cut.

The upper and lower limits are set in the

parameters, but a separate limit switch should

be established and an emergency stop circuit

outside the PLC should be created. Refer to

the term "LIMIT SWITCH".

Lower limit

0

Upper limit

3m

Limit switch

for emergency

stop

Positioning possible in a 3m range

Summary of Contents for A1SD75M1

Page 2: ......

Page 20: ...A 18 MEMO...

Page 22: ...MEMO...

Page 27: ...1 5 MELSEC A 1 PRODUCT OUTLINE MEMO...

Page 42: ...1 20 MELSEC A 1 PRODUCT OUTLINE MEMO...

Page 52: ...2 10 MELSEC A 2 SYSTEM CONFIGURATION MEMO...

Page 111: ...5 21 MELSEC A 5 DATA USED FOR POSITIONING CONTROL MEMO...

Page 115: ...5 25 MELSEC A 5 DATA USED FOR POSITIONING CONTROL MEMO...

Page 123: ...5 33 MELSEC A 5 DATA USED FOR POSITIONING CONTROL MEMO...

Page 127: ...5 37 MELSEC A 5 DATA USED FOR POSITIONING CONTROL MEMO...

Page 167: ...5 77 MELSEC A 5 DATA USED FOR POSITIONING CONTROL MEMO...

Page 193: ...5 103 MELSEC A 5 DATA USED FOR POSITIONING CONTROL MEMO...

Page 276: ...5 186 MELSEC A 5 DATA USED FOR POSITIONING CONTROL MEMO...

Page 332: ...7 18 MELSEC A 7 MEMORY CONFIGURATION AND DATA PROCESS MEMO...

Page 334: ...MEMO...

Page 422: ...9 64 MELSEC A 9 MAIN POSITIONING CONTROL MEMO...

Page 446: ...10 24 MELSEC A 10 ADVANCED POSITIONING CONTROL MEMO...

Page 472: ...11 26 MELSEC A 11 MANUAL CONTROL MEMO...

Page 576: ...12 104 MELSEC A 12 CONTROL AUXILIARY FUNCTIONS MEMO...

Page 745: ......