1

1. Overview

This user's manual explains specifications and names of individual parts of the

CL2XY16-DTP1C5V type CC-Link/LT remote I/O module (hereinafter

abbreviated as remote I/O module).

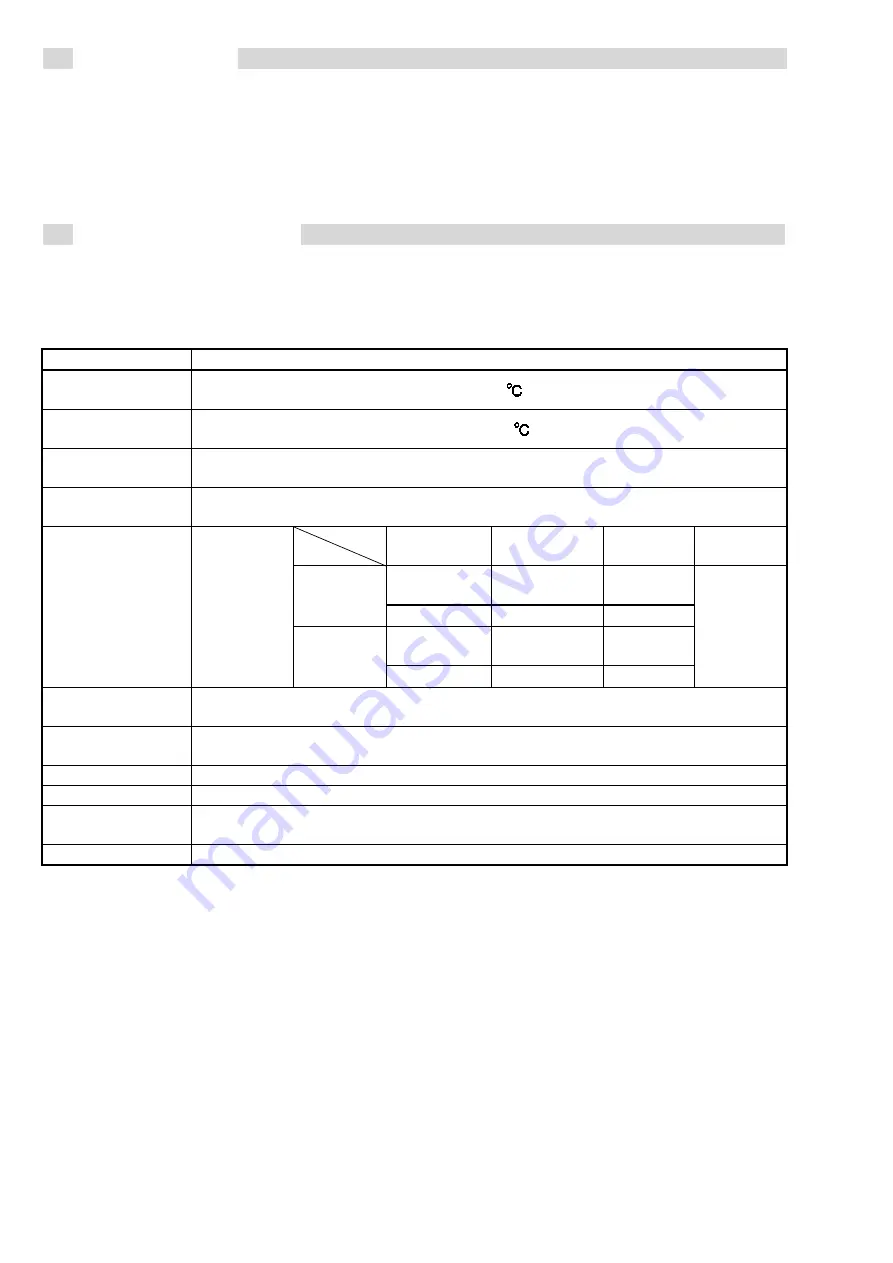

2. Specifications

2.1 General Specifications

The General specifications for the remote I/O module are shown in the following

table.

Item Specifications

Operating ambient

temperature

0 to 55

Storage ambient

temperature

-25 to 75

Operating ambient

humidity

5 to 95%RH, non-condensing

Storage ambient

humidity

5 to 95%RH, non-condensing

Frequency Acceleration Amplitude

Sweep

count

10 to 57Hz

———

0.075mm

(0.003in.)

Under

intermittent

vibration

57 to 150Hz

9.8m/s

2

———

10 to 57Hz

———

0.035mm

(0.001in.)

Vibration

resistance

Conforming

to JIS

B 3502, IEC

61131-2

Under

continuous

vibration

57 to 150Hz

4.9m/s

2

———

10 times

each in

X, Y, Z

directions

(for 80

min.)

Shock resistance

Conforming to JIS B 3502,

IEC 61131-2 (147 m/s

2

, 3 times in each of 3 directions X, Y, Z)

Operating

ambience

No corrosive gases

Operating altitude

2000m (6562ft.) max.

Installation location

Inside control panel *3

Overvoltage

category *1

II max.

Pollution level *2

2 max.

*1: This indicates the section of the power supply to which the equipment is assumed to be

connected between the public electrical power distribution network and the machinery

within premises. Category II applies to equipment for which electrical power is supplied

from fixed facilities.

The surge voltage withstand level for up to the rated voltage of 300 V is 2500 V.

*2: This index indicates the degree to which conductive material is generated in terms of the

environment in which the equipment is used.

Pollution level 2 is when only non-conductive pollution occurs. A temporary conductivity

caused by condensing must be expected occasionally.

*3: It can also be used in an environment other than on the control panel if the conditions such

as usage ambient temperature and humidity are satisfied.