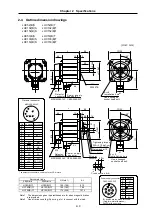

Chapter 2 Specifications

2–11

•

HC702S

•

HC453S

•

HC703S

(Unit : mm)

□

176

58

φ

20

0

45

°

15

0

φ

230

MS3102A22-14P

CE05-2A32-17P

KL

Oil seal

S40608B

75

3

18

44

L

79

21.5

Note 2

+0

.0

1

0

0

0

-0

.0

2

5

φ

11

4.

3

φ

35

Note 2

Note 2

81.

5

Power supply

connector

Detector

connector

4-

φ

13.5

Installation hole

Use a hexagon

socket head bolt.

Note 2

Servomotor type

2000r/min

3000r/min

L

KL

−

HC453S

234

148

HC702S

HC703S

297

211

Note 1. Use a friction coupling (Spun ring, etc.) to connect with the load.

Note 2. This is for the HC702S and HC703S. The HC453S does not have

a screw hole (M8) for the suspension bolt.

Note 3. Refer to section 2-9 for details on the detector connector.

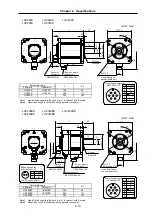

•

HC702BS

•

HC453BS

•

HC703BS

(Unit : mm)

Note 2

11

7

81

.5

0

-0

.0

2

5

φ

11

4.

3

44

L

73.5

KL

Brake connector

MS3102A10SL-4P

CE05-2A32-17P

Oil seal

S40608B

75

3

79

18

+0.

0

1

0

0

φ

35

Note 2

MS3102A22-14P

□

176

58

φ

230

φ

20

0

45

°

15

0

Note 2

21.5

Power supply

connector

Detector

connector

4-

φ

13.5

Installation hole

Use a hexagon

socket head bolt.

Note 2

Servomotor type

2000r/min

3000r/min

L

KL

−

HC453BS

282

148

HC702BS

HC703BS

345

211

Note 1. Use a friction coupling (Spun ring, etc.) to connect with the load.

Note 2. This is for the HC702BS and HC703BS. The HC453BS does not have a screw hole (M8) for the suspension bolt.

Note 3. Refer to section 2-9 for details on the detector connector.

Brake connector

MS3102A10SL-4P

Signal

B1

B2

B

A

Pin

A

B

24VDC with no polarity.

CE05-2A32-17P

D

Signal

U

V

W

B

A

Pin

C

A

B

C

D

Power supply connector

Grounding

CE05-2A32-17P

D

Signal

U

V

W

B

A

Pin

C

A

B

C

D

Power supply connector

Grounding