F940GOT Series(F94*GOT-*WD-E)

Installation Manual

JY992D94201E

This manual contains text, diagrams and explanations which will guide the reader in the correct

installation, safe use and operation of the F94*GOT-*WD-E and should be read and understood before

attempting to install or use the unit. Further information can be found in the associated manuals list below.

Specifications are subject to change without notice

Guidelines for the Safety of the User and Protection of the

F94*GOT-*WD-E

This manual has been written to be used by trained and competent personnel. The definition of such a

person or persons is as follows:

a) Any engineer using the product associated with this manual, should be of a competent nature,

trained and qualified to the local and national standards. These engineers should be fully aware of

all aspects of safety with regards to automated equipment.

b) Any commissioning or service engineer must be of a competent nature, trained and qualified to

the local and national standards.

c)

All operators of the completed equipment should be trained to use that product in a safe and

co-ordinated manner in compliance to established safety practices.

Note:

The term ‘completed equipment’ refers to a third party constructed device which contains or uses

the product associated with this manual.

Note’s on the Symbols Used in this Manual

At various times through out this manual certain symbols will be used to highlight points of information

which are intended to ensure the users personal safety and protect the integrity of equipment.

1) Indicates that the identified danger

WILL

cause physical and property damage.

2) Indicates that the identified danger could

POSSIBLY

cause physical and property

damage.

•

Under no circumstances will Mitsubishi Electric be liable or responsible for any consequential damage

that may arise as a result of the installation or use of this equipment.

•

All examples and diagrams shown in this manual are intended only as an aid to understanding the

text, not to guarantee operation. Mitsubishi Electric will accept no responsibility for actual use of the

product based on these illustrative examples.

•

Owing to the very great variety in possible application of this equipment, you must satisfy yourself as

to its suitability for your specific application.

Associated Manuals

Manual Name

Manual Number

Description

|

F940GOT Series

(F94*GOT-*WD-E)

Installation Manual

JY997D94201

Describes the specifications, wiring, and

installation of F940GOT Series graphic

operation terminal. (hardware)

~

GOT-F900

OPERATION MANUAL

(describes GT Designer2)

JY992D09101

(separate volume)

Describes the operation and use of the GOT-

F900 Series graphic operation terminals and

GT Designer2.

~

GOT-F900 Series

Operation Manual

JY992D94701

(separate volume)

Describes the operation and use of the GOT-

F900 Series graphic operation terminals, GT

Designer and FX-PCS-DU/WIN-E.

~

GOT-F900 Series

Hardware Manual

(connection diagram)

JY992D94801

(separate volume)

Describes wiring and installation of the GOT-

F900 Series graphic operation terminals.

|

GT Designer2 Version1

Operating Manual

(PDF files on CD-ROM

included with product)

Describes the operation of GT Designer2

(SW*D5C-GTD2-E) and data transfer to the

GOT-900 Series.

|

GT Designer2 Version1

Reference Manual

(PDF files on CD-ROM

included with product)

Describes the specifications and setting of

object functions in GT Designer2 (SW*D5C-

GTD2-E).

|

GT Designer

Operating Manual

Included with the screen

creation software

Describes the operation of GT Designer

(SW*D5C-GOTR-PACKE) and data transfer to

the GOT-900 Series. (Refer to the help file)

|

FX-PCS-DU/WIN-E

SOFTWARE MANUAL

JY992D68301

(included with the screen

creation software)

Describes the operation of FX-PCS-DU/WIN-

E screen creation software.

F9GT-40FMB

User’s Manual

JY992D98601

This manual contains explanations for

installation and operating procedure of F9GT-

40FMB data transfer adapter.

~

Indispensable manual

|

Either manual is necessary.

Refer if necessary, please.

Refer to the manual of the connected programmable controller for details concerning that unit.

1. Introduction

The F940GOT-*WD-E (hereafter called “GOT” or “F940GOT”) is

to be mounted on the face of a control panel or operations panel,

and connected to the programming por t (CPU por t) or the

communication port (communication port) of a PLC.

Various devices can be monitored and PLC data changed via the

GOT screens. Several display screens are built-in to the GOT,

and additional personalized screens can be created by the user.

1) The GOT can connect to MELSEC FX, A, QnA and Q PLCs

as well as a host of third party manufactured units. Further

information can be found in GOT-F900 Series Hardware

Manual.

2) PLC user programs can be downloaded, uploaded and

monitored using programming software GX-Developer or FX-PCS/WIN-E on a personal computer via

the GOT. Further information can be found in the GOT-F900 Series Operation Manual.

3) Display screens are created using the following software.

1.1 Product Lists

Caution

During abnormal communication (including cable breakages) when monitor is executed within

the GOT, communication between the GOT and programmable controller CPU is interrupted.

It is then impossible to operate switches or devices in the PLC through the GOT.

Communication and normal operation resumes when the GOT system is correctly configured.

DO NOT configure emergency stop or safety features to operate through the GOT, and be

sure that there is no adverse consequences in the event of a GOT - PLC communications

malfunction.

F9GT-40UMB

Manual

JY992D74101

This manual contains explanations for

installation and operating procedure of F9GT-

40UMB data transfer adapter.

Software Name

Version

GT Designer2

SW

D5C-GTD2-E

(

indicates version)

GOT-F900 and GOT-A900 Series (for Windows) screen creation software.

GT Designer

SW

D5C-GOTR-PACKE

(

indicates version)

GOT-F900 and GOT-A900 Series (for Windows) screen creation software.

SW1-A edition of SW1D5C-GOTR-PACKE or later

FX-PCS-DU/WIN-E

GOT-F900 Series (for Windows) screen creation software.

SW0PC-FXDU/WIN-E version 2.00 or later

Production Name

Description

F940GOT-SWD-E

Graphic operation terminal main unit

SWD: 8 colors

LWD: White and black

F940GOT-LWD-E

FX-50DU-CAB0

Communication cable (GOT

↔

CPU port in FX

0

, FX

0S

, FX

1S

, FX

0N

, FX

1N

, FX

2N

or FX

2NC

series PLC)

The connector on the GOT side is wired straight.

Cable length is 3m (9' 10").

FX-50DU-CAB0/EN

Communication cable (GOT

↔

CPU port in FX

0

, FX

0S

, FX

1S

, FX

0N

, FX

1N

, FX

2N

or FX

2NC

series PLC)

The connector on the GOT side is wired straight. Cable length is 3m (9' 10").

FX-50DU-CAB0-**M

Communication cable (GOT

↔

CPU port in FX

0

, FX

0S

, FX

1S

, FX

0N

, FX

1N

, FX

2N

or FX

2NC

series PLC)

The connector on the GOT side is wired straight.

** M is cable length. 1M: 1m (3' 3"), 10M: 10m (32' 9"), 20M: 20m (65' 7"),

30M: 30m (98' 5")

FX-40DU-CAB

Communication cable (GOT

↔

CPU port in FX, FX

2C

, A or QnA series PLC)

The connector on the GOT side is wired straight. Cable length is 3m (9' 10").

FX-40DU-CAB-**M

Communication cable (GOT

↔

CPU port in FX, FX

2C

, A or QnA series PLC)

The connector on the GOT side is wired straight.

** M is cable length. 10M: 10m (32' 9"), 20M: 20m (65' 7"), 30M: 30m (98' 5")

QC30R2

Communication cable (GOT

↔

CPU port in Q series PLC)

The connector on the GOT side is wired straight. Cable length is 3m (9' 10").

FX-232CAB-1

Data exchange cable (GOT

↔

Personal computer <9-pin D-sub>)

PM-20BL

Battery for Alarm history, sampling and current time data retertion.

F9GT-40PSC

Transparent protection sheet for F940GOT (5 pieces)

F9GT-40LTS

Backlight for F940GOT

F9GT-40UMB

Data transfer adapter

F9GT-40FMB

Data transfer adapter (Flash memory built in)

Manual Name

Manual Number

Description

P L C

P r o g r a m m i n g

p o r t

G O T

Note;

•

Do not lay signal cables near high voltage power cables or allow them to share the same

trunking duct, otherwise, effects of noise or surge induction are likely to take please. Keep

a safe distance of more than 100 mm from these wires.

•

Operate touch switches on the display screen by hand.

DO NOT use excessive force, or attempt operate them with hard or pointed objects.

The tip of a screw driver, pen or similar object for example may break the screen.

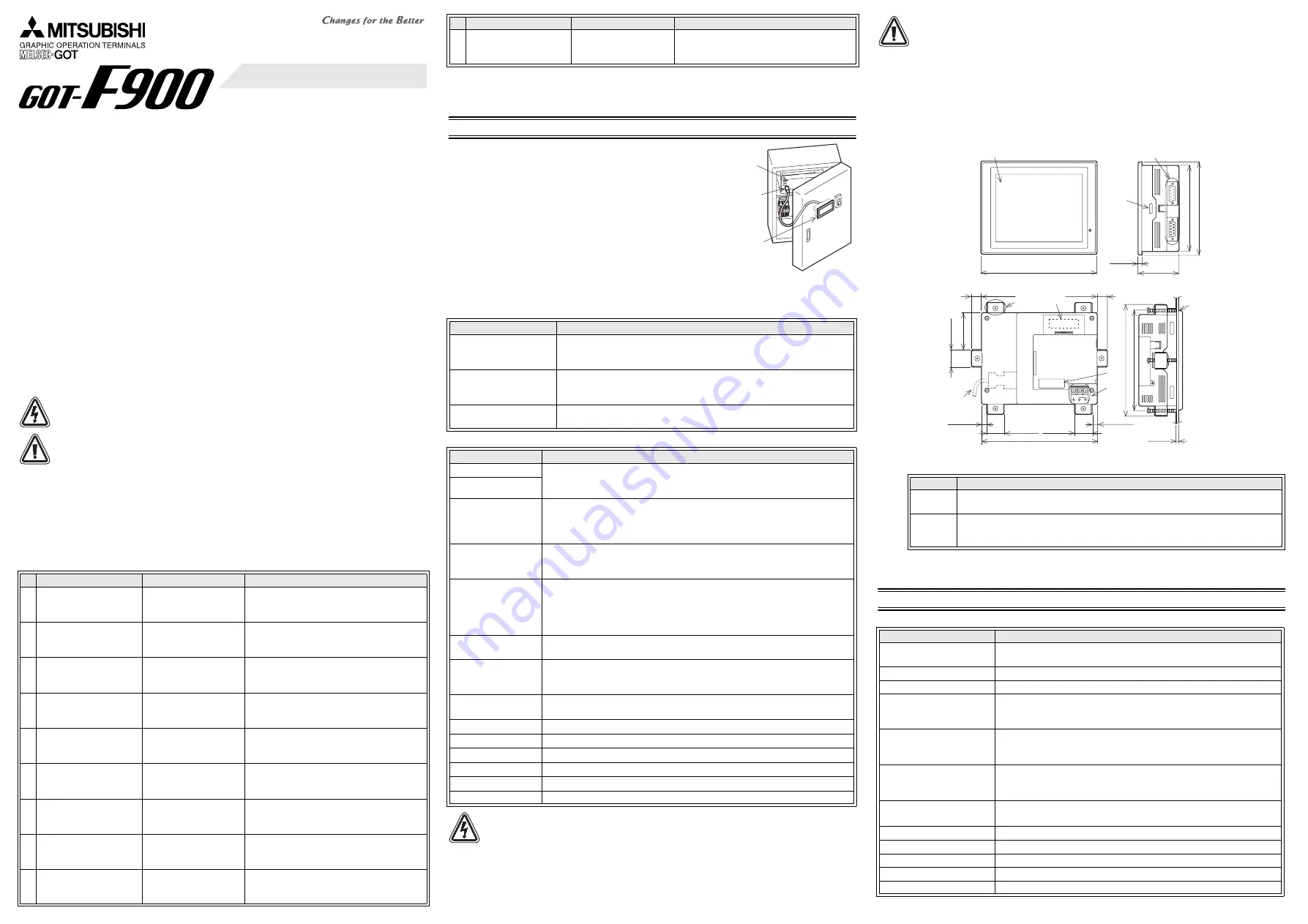

1.2 Dimensions and Each Part Name

Dimensions: mm (inches)

MASS (Weight): 1 kg (2.2 lbs)

Accessory:

Mounting brackets, Tightening bolt (M3, 6 bolts),

Packing seal for dust and water resistance

a) Display

b) Mounting bracket hole

c)

Communication ports

d) Mounting bracket and tightening bolt

e) PM-20BL battery

f)

Expansion interface

g) DC power supply terminal (M3)

h) Communication cable

i)

Packing seal

2. Specifications

2.1 General Specifications

Port

Description

RS-422

RS-422 Port for connecting either a PLC (including1:N connection) or

communication (computer link) unit <9-pin D-sub>

RS232C

RS-232C port for connecting eirher a personal computer, printer, bar-code reader

or 1:N connection

<9-pin D-sub>

Item

Specifications

Operating Temperature

0 ~ 50 °C (32 ~ 122 °F)

[With expansion module: 0 ~ 40 °C (32 ~ 104 °F)]

Storage Temperature

-20 ~ 60 °C (-4 ~ 140 °F)

Humidity

35 ~ 85% Relative Humidity, No condensation

Operating atmosphere

Must be free of lamp black, corrosive gas, flammable gas, or excessive

amount of electroconductive dust particles and must be no direct

sunlight. (Same as for saving)

Vibration Resistance

- intermittent vibration

10 ~ 57 Hz: 0.075 mm Half Amplitude

57 ~ 150 Hz: 9.8 m/s

2

Acceleration

Sweep Count for X, Y, Z: 10 times (80 min. in each direction)

Vibration Resistance

- Continuous vibration

10 ~ 57 Hz: 0.035 mm Half Amplitude

57 ~ 150 Hz: 4.9 m/s

2

Acceleration

Sweep Count for X, Y, Z: 10 times (80 min in each direction)

Shock Resistance

147m/s

2

Acceleration,

3 times in each direction X, Y, and Z

Noise Immunity

1000 Vp-p, 1micro second, 30 ~ 100 Hz, tested by noise simulator

Dielectric Withstand Voltage

500 V AC > 1 min, tested between power terminals and ground

Insulation Resistance

5 M

Ω

> at 500 V DC, tested between power terminals and ground

Ground

Grounding resistance of 100

Ω

or less. (class D)

Protection

IP 65F

48

.5

(1

.9

0"

)

23

(0

.9

1"

)

-

+

2 4 V D C

1 0 ( 0 . 3 9 " )

d )

1 0 ( 0 . 3 9 " )

h )

g )

f )

e )

14

0(

5.

51

")

13

0(

5.

12

")

1 5 2 ( 5 . 9 8 " )

6 . 5 ( 0 . 2 5 " )

2 3 ( 0 . 9 1 " ) 2 3 ( 0 . 9 1 " )

6 . 5 ( 0 . 2 5 " )

5 ( 0 . 2 0 " )

i )

P O W E R

R

S

23

2C

R

S

42

2

5 7 ( 2 . 2 4 " )

5 ( 0 . 2 0 " )

a )

1 6 2 ( 6 . 3 8 " )

b )

c )

12

0(

4.

72

")

13

0(

5.

12

")