2-3

VEHICLE ELECTRICAL COMPONENTS

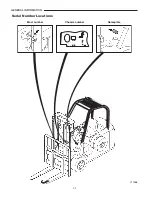

Selection of KPH or MPH

1.

Apply the parking brake.

2.

Place the direction lever in NEUTRAL.

3.

Turn the key switch to the

I

(ON) position.

4.

Push and hold button 1 for one to two seconds.

NOTICE

:

Display will show KPH and a 24-hour clock

until it is changed. When MPH is selected, the

clock will change to a 12-hour clock.

Setting the clock

1.

Apply the parking brake.

2.

Place the direction lever in NEUTRAL.

3.

Turn the key switch to the

I

(ON) position.

4.

Push and hold button

1

until the minutes’ display

flashes.

5.

Release button

1

.

6.

Adjust the minutes with button

2

.

7.

Push button

1

and release when the hours’ display

flashes.

8.

Adjust the hour with button

2

.

9.

Push button

1

to lock in the time.

103043